-

What happened?

Workers were drilling after bottom hole assembly (BHA) bit trip.

A worker observed an increase in gas flow and discovered a fire at the shakers.

The driller shut off the pump, left the rig floor and went to the accumulator house to secure the well.

Local fire department attended to put out the fire.

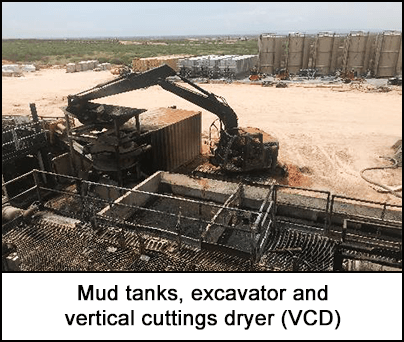

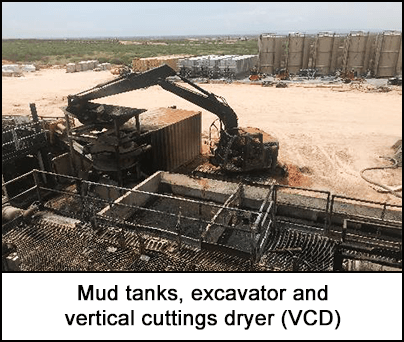

No loss of containment occurred. There was damage to the shaker tank, rig substructure and track hoe.

-

Why did it happen?

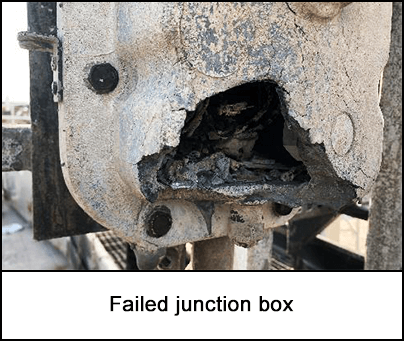

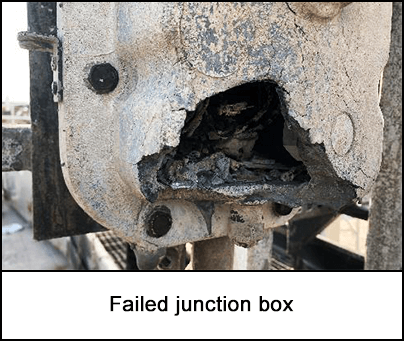

A failure of the electrical system at the shaker and mud pit tanks was the probable ignition source.

No procedure in place for managing trip gas – which was circulating down the flow line at the time.

Inadequate configuration for the volume of tripping gas - system was reliant on a vent line coming off the flow line to handle the gas.

-

What did they learn?

Verify the integrity of rig electrical systems.

Establish standards for the mud/gas separator flow path configurations and managing gas at the surface.

- Modify existing rig separator configurations as required.

Confirm all workers had been trained and are competent to perform their duties.

Strategically locate firefighting materials and ensure communication with fire support services.

-

Ask yourself or your crew

Have you ever had a fire on your worksite? What happened?

How do we manage tripping gas on our site? What more could we do?

What should you do if you discover a fire?

Do we have a designated person onsite that communicates with the fire support services? If not, should we have one?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

Workers were drilling after bottom hole assembly (BHA) bit trip.

A worker observed an increase in gas flow and discovered a fire at the shakers.

The driller shut off the pump, left the rig floor and went to the accumulator house to secure the well.

Local fire department attended to put out the fire.

No loss of containment occurred. There was damage to the shaker tank, rig substructure and track hoe.

Why did it happen?

A failure of the electrical system at the shaker and mud pit tanks was the probable ignition source.

No procedure in place for managing trip gas – which was circulating down the flow line at the time.

Inadequate configuration for the volume of tripping gas - system was reliant on a vent line coming off the flow line to handle the gas.

What did they learn?

Verify the integrity of rig electrical systems.

Establish standards for the mud/gas separator flow path configurations and managing gas at the surface.

- Modify existing rig separator configurations as required.

Confirm all workers had been trained and are competent to perform their duties.

Strategically locate firefighting materials and ensure communication with fire support services.

Ask yourself or your crew

Have you ever had a fire on your worksite? What happened?

How do we manage tripping gas on our site? What more could we do?

What should you do if you discover a fire?

Do we have a designated person onsite that communicates with the fire support services? If not, should we have one?

Workers were drilling when they noticed an increase in gas flow to their area and discovered a fire. There were no injuries to personnel but damage to equipment.