-

What happened?

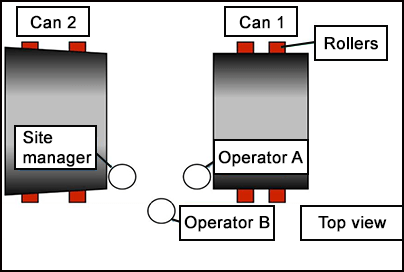

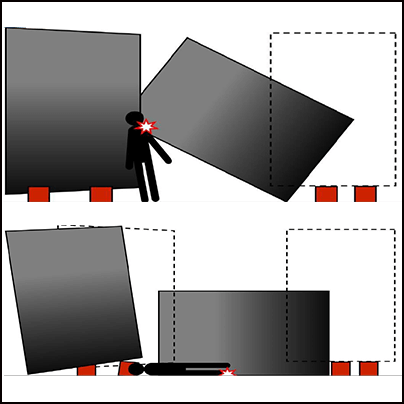

During work on a wind turbine foundation, Technicians A and B were grinding cans back-to-back while the cans were positioned on rollers.

The technicians would grind the can surface, turn it by a third, and continue grinding until the whole can was completed.

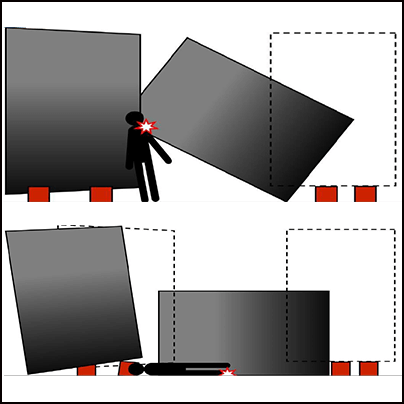

A can weighing 9 tonnes spiraled off the rolling assembly. Technician A noticed the sudden movement of the can and tried to pull technician B behind him and away from the line of fire.

As a result, the jacket can grazed technician A’s hand.

Technician B was in the line of fire and was subjected to a blow on the right humerus and suffered a foot injury when the flat bevel edge of the can fell on his foot.

All work was stopped. First aid was provided on site and the injured technician was transported to hospital by ambulance. Sadly, the foot injury resulted in amputation.

-

Why did it happen?

Improper work environment

- The workstation for the cans were placed 3 metres (10 feet) apart and directly in front of each other. This allowed the technicians to work back-to-back, leaving them directly in the line of fire.

- The rollers for each can were not firmly secured down to the floor or braced which allowed movement during rotations.

Insufficient planning of work activities/control of work (COW)

- Workers stated that the work procedure at that time allowed them to move or rearrange the machines if necessary, allowing them to utilize the limited assigned working space in the fabrication yard.

- When the technicians would mechanically turn the cans, they would first have to stand away from the line of fire and then use the wireless controller to start the rotation.

Complacency

- There were no pre-use checks of the equipment.

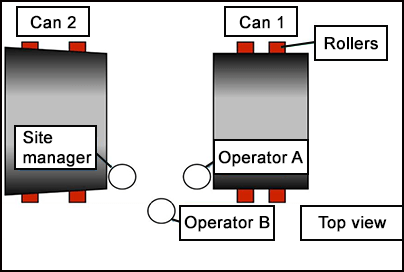

- After the incident occurred, the rollers and cans were placed horizontally and space between each roller was extended by 2 metres (6.5 feet).

-

What did they learn?

Working back-to-back should not be allowed.

When technicians mechanically turn cans, they should step away from the line of fire.

Conduct toolbox talk to remind technicians of the potential risk of being in the line of fire.

Ensure that all personnel responsible for writing, reviewing, or approving Risk Assessment and Method Statements (RAMS) are trained to do so. Retrain personnel and update RAMS if necessary.

Evaluate engineering solutions for safer work practices.

-

Ask yourself or your crew

How can something like this happen on our site?

What safety measures (i.e. procedures, controls/barriers) do we have in place to mitigate the risk? How do we know if they are working?

How do you ensure you stay out of the line of fire at all times?

What should you do if you see a colleague working in unsafe conditions?

What improvements or changes should we make to the procedures, controls/barriers, or the way we work?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

During work on a wind turbine foundation, Technicians A and B were grinding cans back-to-back while the cans were positioned on rollers.

The technicians would grind the can surface, turn it by a third, and continue grinding until the whole can was completed.

A can weighing 9 tonnes spiraled off the rolling assembly. Technician A noticed the sudden movement of the can and tried to pull technician B behind him and away from the line of fire.

As a result, the jacket can grazed technician A’s hand.

Technician B was in the line of fire and was subjected to a blow on the right humerus and suffered a foot injury when the flat bevel edge of the can fell on his foot.

All work was stopped. First aid was provided on site and the injured technician was transported to hospital by ambulance. Sadly, the foot injury resulted in amputation.

Why did it happen?

Improper work environment

- The workstation for the cans were placed 3 metres (10 feet) apart and directly in front of each other. This allowed the technicians to work back-to-back, leaving them directly in the line of fire.

- The rollers for each can were not firmly secured down to the floor or braced which allowed movement during rotations.

Insufficient planning of work activities/control of work (COW)

- Workers stated that the work procedure at that time allowed them to move or rearrange the machines if necessary, allowing them to utilize the limited assigned working space in the fabrication yard.

- When the technicians would mechanically turn the cans, they would first have to stand away from the line of fire and then use the wireless controller to start the rotation.

Complacency

- There were no pre-use checks of the equipment.

- After the incident occurred, the rollers and cans were placed horizontally and space between each roller was extended by 2 metres (6.5 feet).

What did they learn?

Working back-to-back should not be allowed.

When technicians mechanically turn cans, they should step away from the line of fire.

Conduct toolbox talk to remind technicians of the potential risk of being in the line of fire.

Ensure that all personnel responsible for writing, reviewing, or approving Risk Assessment and Method Statements (RAMS) are trained to do so. Retrain personnel and update RAMS if necessary.

Evaluate engineering solutions for safer work practices.

Ask yourself or your crew

How can something like this happen on our site?

What safety measures (i.e. procedures, controls/barriers) do we have in place to mitigate the risk? How do we know if they are working?

How do you ensure you stay out of the line of fire at all times?

What should you do if you see a colleague working in unsafe conditions?

What improvements or changes should we make to the procedures, controls/barriers, or the way we work?

During work on a wind turbine foundation, two technicians were grinding cans back-to-back while the cans were positioned on the rollers. A can weighing 9 tonnes spiraled off the rolling assembly, severely injuring one of the technicians.