-

What happened?

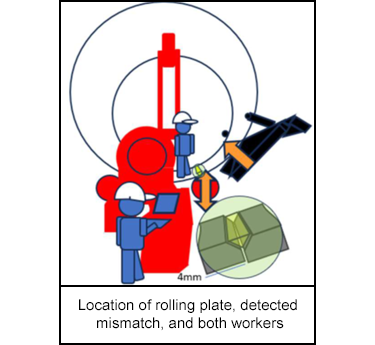

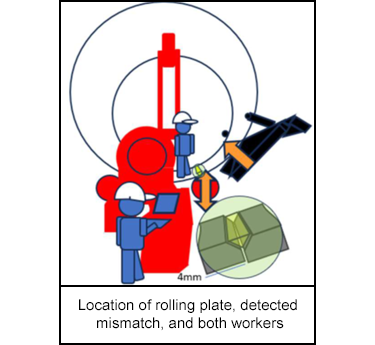

A steel plate rolling machine was being used to manufacture components for offshore wind.

Two workers were involved in the operation, one at the control desk and the other providing support.

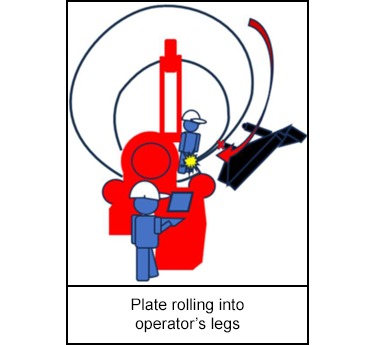

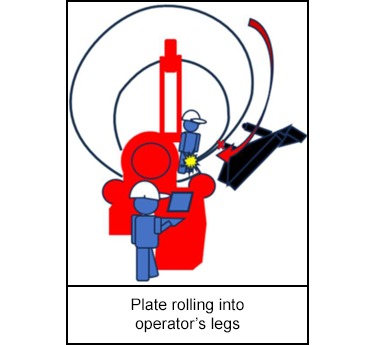

The steel plate was being rolled when a slight mismatch was detected. The support worker entered the machine to try and fix this. The worker at the controls pushed the plate when his colleague was still inside, producing an unexpected movement that caused him serious injuries.

-

Why did it happen?

The workers didn’t follow the established work instruction or their training: they did not vacate the machine before starting the rolling operation, and they started operation of the machine before confirming that nobody was inside it.

Misjudgement of potential plate movement reactions.

Slight over-rolling on plate might have made the plate movement easier.

-

What did they learn?

Do not stand in locations where the steel plate may reach you if something goes wrong (line of fire).

Strictly follow established procedures and instructions.

Implement refresher training to understand potential consequences of non-compliance with operating procedure and established safety barriers and controls.

The company gained a better understanding that unexpected events or decisions can still happen and accidents can take place, even when machines are CE certified, external safety barriers have been implemented, operating procedures described and the operators trained in them.

Promote the continuous improvement of machinery safety, including new safety devices and safer designs, in cooperation with machine manufacturers.

-

Ask yourself or your crew

How can something like this happen here?

What can we do to prevent this type of incident?

What would you do if your colleague tells you not to follow the rules and take a shortcut?

What should you do if you observe somebody working in an unsafe manner? How can we help them? If they do not react to your suggestion, is there anything more you can do?

Have you thought what may happen if the equipment you are handling fails, or somebody acts in the wrong way? What basic precautionary measures can you take so as not to be in the line of fire?

How can we, as a team, strengthen our safety culture to ensure that we don’t collectively overlook significant deviations from established rules?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A steel plate rolling machine was being used to manufacture components for offshore wind.

Two workers were involved in the operation, one at the control desk and the other providing support.

The steel plate was being rolled when a slight mismatch was detected. The support worker entered the machine to try and fix this. The worker at the controls pushed the plate when his colleague was still inside, producing an unexpected movement that caused him serious injuries.

Why did it happen?

The workers didn’t follow the established work instruction or their training: they did not vacate the machine before starting the rolling operation, and they started operation of the machine before confirming that nobody was inside it.

Misjudgement of potential plate movement reactions.

Slight over-rolling on plate might have made the plate movement easier.

What did they learn?

Do not stand in locations where the steel plate may reach you if something goes wrong (line of fire).

Strictly follow established procedures and instructions.

Implement refresher training to understand potential consequences of non-compliance with operating procedure and established safety barriers and controls.

The company gained a better understanding that unexpected events or decisions can still happen and accidents can take place, even when machines are CE certified, external safety barriers have been implemented, operating procedures described and the operators trained in them.

Promote the continuous improvement of machinery safety, including new safety devices and safer designs, in cooperation with machine manufacturers.

Ask yourself or your crew

How can something like this happen here?

What can we do to prevent this type of incident?

What would you do if your colleague tells you not to follow the rules and take a shortcut?

What should you do if you observe somebody working in an unsafe manner? How can we help them? If they do not react to your suggestion, is there anything more you can do?

Have you thought what may happen if the equipment you are handling fails, or somebody acts in the wrong way? What basic precautionary measures can you take so as not to be in the line of fire?

How can we, as a team, strengthen our safety culture to ensure that we don’t collectively overlook significant deviations from established rules?

During a plate rolling operation, a slight mismatch was detected, yet one worker pushed the plate while his colleague was still inside, resulting in severe leg injuries.

For insights into a similar incident, please visit: Bending machine fatality.