-

What happened?

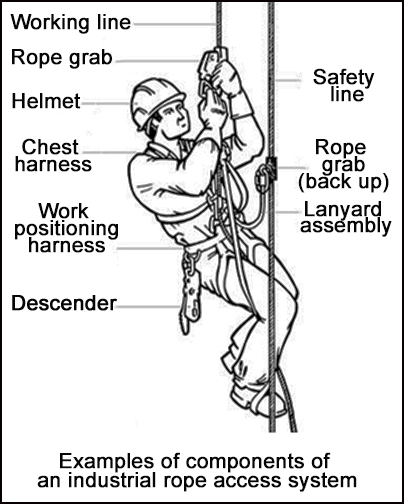

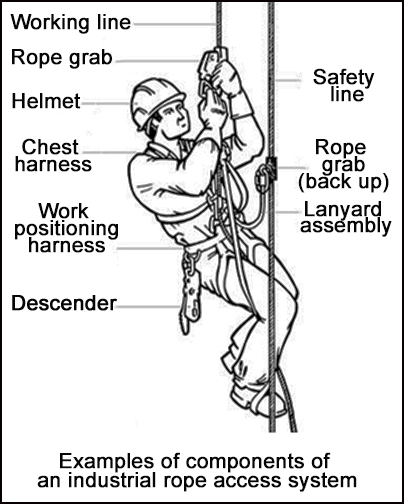

Two serious incidents occurred when workers were using rope access systems.

Incident 1 – Rope failure incident

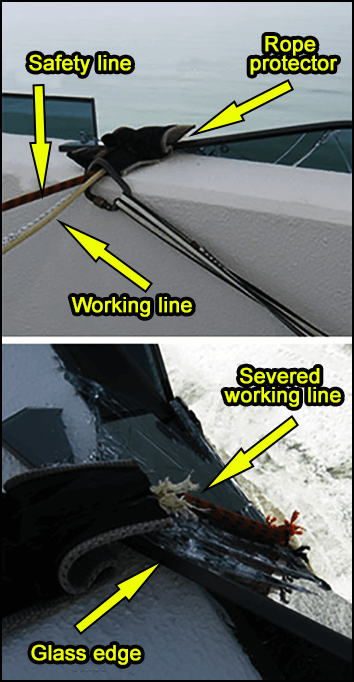

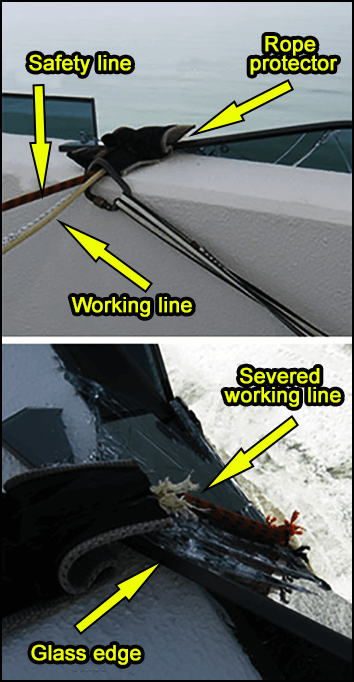

The working line and safety line were set up to pass over the top of a glass balustrade.

The glass panel smashed, cutting the working line and damaging the safety line.

The worker fell several floors before the rope grab on the second (safety) line locked onto the rope.

They repeatedly struck the building and were injured.

Incident 2 – Pendulum incident

The worker was standing on a ledge of the building while still connected to the suspension system.

They moved a horizontal distance away from the original vertical path of the suspension lines.

They fell and a pendulum effect occurred.

They swung across the face of the building 15 metres (50 feet) before hitting a window on a balcony.

-

Why did it happen?

Rope failure incident:

- The load from the ropes caused the glass panel to break, cutting the working and safety lines.

- The rope grab device should have locked the safety rope – the worker should not have fallen so far before he stopped.

- Photographs 1 and 2 show the working line and safety line passing over the top of a glass balustrade following the incident

Pendulum incident:

- The worker was using an incorrect set up and was not working directly below the anchor point.

-

What did they learn?

Workers should be provided with appropriate instruction, training, and supervision.

Working and safety lines should never pass over glass panels or sharp edges. Where working and safety lines have to pass over an edge, protection should be installed to prevent damage to the lines.

Ensure that:

- A suitable work method statement is developed, and it includes suitable anchor points.

- The rope grab device is fit for purpose.

- Minimum two competent workers are on site for any working at height activity.

- The structure is capable of safely withstanding shock loading.

- A rescue plan is developed and tested every year.

Anchor plans and instructions for use should be referenced before conducting risk assessments.

-

Ask yourself or your crew

What are the hazards of moving horizontally while connected to a vertical suspension system?

Do any of your working and safety lines have to pass over glass panels or sharp edges? What protection should we install to prevent the lines from becoming damaged?

What other hazards are there when working at height?

What are our procedures for working at height? How can we improve them?

Do you have a rescue plan? What is it?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

Two serious incidents occurred when workers were using rope access systems.

Incident 1 – Rope failure incident

The working line and safety line were set up to pass over the top of a glass balustrade.

The glass panel smashed, cutting the working line and damaging the safety line.

The worker fell several floors before the rope grab on the second (safety) line locked onto the rope.

They repeatedly struck the building and were injured.

Incident 2 – Pendulum incident

The worker was standing on a ledge of the building while still connected to the suspension system.

They moved a horizontal distance away from the original vertical path of the suspension lines.

They fell and a pendulum effect occurred.

They swung across the face of the building 15 metres (50 feet) before hitting a window on a balcony.

Why did it happen?

Rope failure incident:

- The load from the ropes caused the glass panel to break, cutting the working and safety lines.

- The rope grab device should have locked the safety rope – the worker should not have fallen so far before he stopped.

- Photographs 1 and 2 show the working line and safety line passing over the top of a glass balustrade following the incident

Pendulum incident:

- The worker was using an incorrect set up and was not working directly below the anchor point.

What did they learn?

Workers should be provided with appropriate instruction, training, and supervision.

Working and safety lines should never pass over glass panels or sharp edges. Where working and safety lines have to pass over an edge, protection should be installed to prevent damage to the lines.

Ensure that:

- A suitable work method statement is developed, and it includes suitable anchor points.

- The rope grab device is fit for purpose.

- Minimum two competent workers are on site for any working at height activity.

- The structure is capable of safely withstanding shock loading.

- A rescue plan is developed and tested every year.

Anchor plans and instructions for use should be referenced before conducting risk assessments.

Ask yourself or your crew

What are the hazards of moving horizontally while connected to a vertical suspension system?

Do any of your working and safety lines have to pass over glass panels or sharp edges? What protection should we install to prevent the lines from becoming damaged?

What other hazards are there when working at height?

What are our procedures for working at height? How can we improve them?

Do you have a rescue plan? What is it?

Two serious incidents occurred causing injuries to workers due to the incorrect selection and use of rope access systems.