-

What happened?

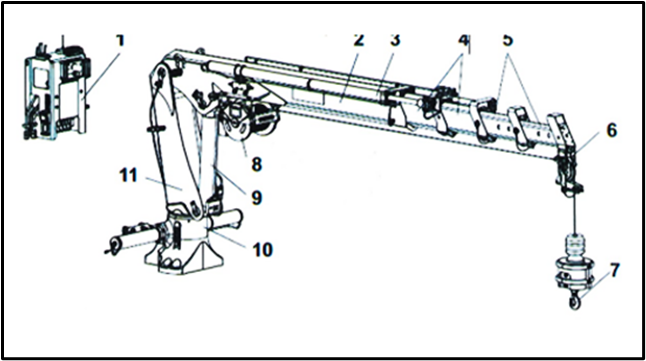

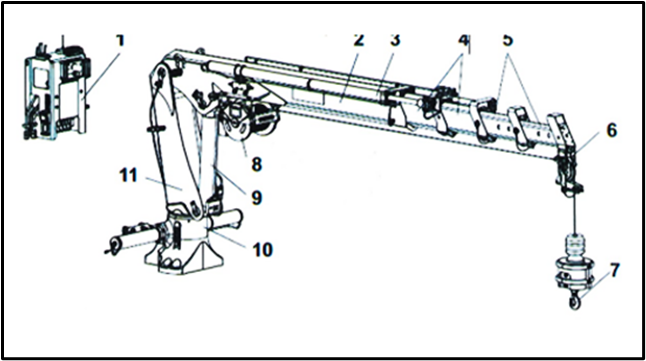

A team of technicians had been working to install a new secondary evacuation retrofit. This task requires manual extension on the nacelle crane (HIAB) to be deployed.

Once the task was completed, two technicians stayed in the nacelle to finalise the craning and retract the manual HIAB extension.

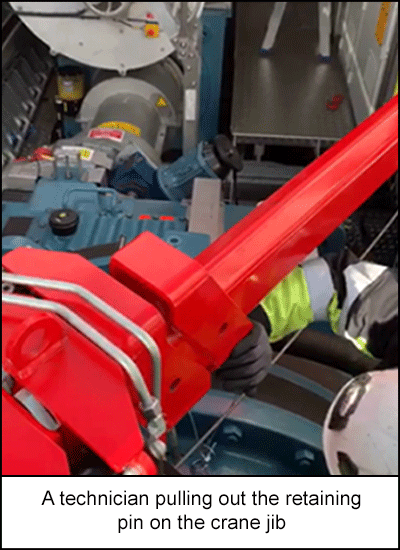

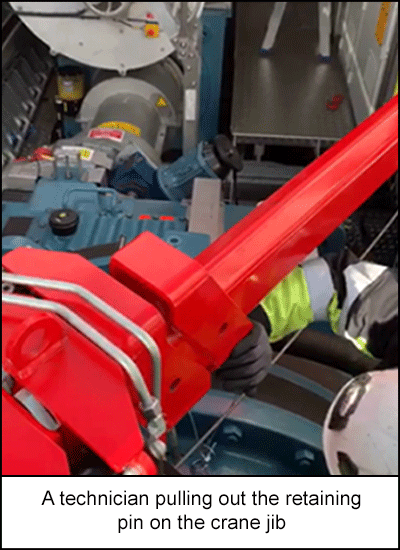

One of the technicians pulled out the retaining pin on the crane jib and the manual extension retracted in an uncontrolled manner crushing their hand in the jib.

The injured technician then descended to the crew transfer vessel (CTV) and received first aid.

The incident resulted in two broken bones to the back of the hand.

-

Why did it happen?

The task allowed / required the worker to place their hand close to a pinch point which resulted in their hand being crushed.

It has not been identified that there is an uncontrolled risk that could result in a significant injury. There was no evidence that the task had been risk assessed.

In all the existing procedures the critical control measures are either not identified at all or are included but not in a logical and clear way.

Unclear procedures - the critical control measures were either not identified, or included but not in a logical and clear way.

-

What did they learn?

- The technician carried out the task in accordance with the instruction in the OEM manual for the crane.

- There is a lack of risk assessment, work instruction and training for this task.

A robust system needs to be developed encompassing all these factors with improved risk mitigations to prevent reoccurrence.

-

Ask yourself or your crew

What would we do in this situation?

How can something like this happen here?

How can we improve the way we do this task?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A team of technicians had been working to install a new secondary evacuation retrofit. This task requires manual extension on the nacelle crane (HIAB) to be deployed.

Once the task was completed, two technicians stayed in the nacelle to finalise the craning and retract the manual HIAB extension.

One of the technicians pulled out the retaining pin on the crane jib and the manual extension retracted in an uncontrolled manner crushing their hand in the jib.

The injured technician then descended to the crew transfer vessel (CTV) and received first aid.

The incident resulted in two broken bones to the back of the hand.

Why did it happen?

The task allowed / required the worker to place their hand close to a pinch point which resulted in their hand being crushed.

It has not been identified that there is an uncontrolled risk that could result in a significant injury. There was no evidence that the task had been risk assessed.

In all the existing procedures the critical control measures are either not identified at all or are included but not in a logical and clear way.

Unclear procedures - the critical control measures were either not identified, or included but not in a logical and clear way.

What did they learn?

- The technician carried out the task in accordance with the instruction in the OEM manual for the crane.

- There is a lack of risk assessment, work instruction and training for this task.

A robust system needs to be developed encompassing all these factors with improved risk mitigations to prevent reoccurrence.

Ask yourself or your crew

What would we do in this situation?

How can something like this happen here?

How can we improve the way we do this task?

A team of technicians had been working to install a new secondary evacuation retrofit. This task requires manual extension on the nacelle crane (HIAB) to be deployed. One of the technicians pulled out the retaining pin on the crane jib and the manual extension retracted in an uncontrolled manner crushing their hand in the jib.