-

What happened?

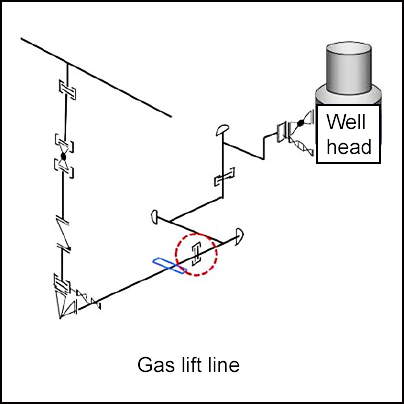

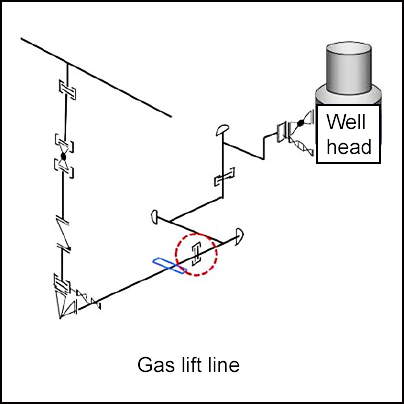

Repairs were scheduled to a gas lift line as part of platform shutdown maintenance.

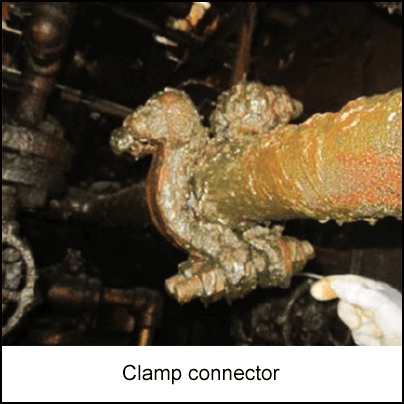

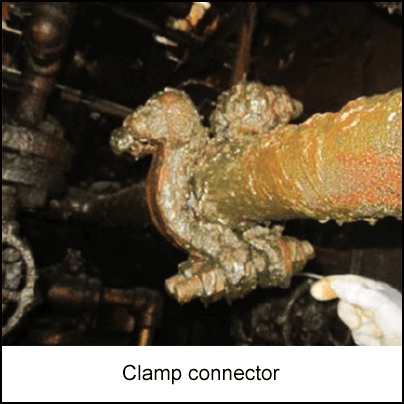

Four workers were trying to remove a grayloc clamp located on a gas lift line.

One of the four bolts was removed, and the other three were cut off when removing the clamp.

A worker knocked on the clamp with a brass hammer to free the connection.

A hydrocarbon release occurred (the fluid in production causing annulus).

-

Why did it happen?

Production casing valve on the wellhead was stuck.

- This limited workers’ ability to prove that there was no energy on the well-side of the gas lift choke.

Workers thought zero energy was demonstrated before starting work.

Isolation work and verification was not fully effective (revealed by investigation).

-

What did they learn?

Verify and recognise the production casing valve’s integrity.

Evaluate the knowledge of workers. Ensure they are trained and understand:

- Interfaces between surface and subsurface equipment

- Work management requirements for isolation control

- Independent verification of zero energy

Provide appropriate training if required.

-

Ask yourself or your crew

What should the workers have done differently?

What pre-use checks should you do before maintenance works on well gas lines?

How do you confirm production casing valve integrity? Why is that important?

What measures do we have in place to prevent this from happening on our site? How can we improve?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

Repairs were scheduled to a gas lift line as part of platform shutdown maintenance.

Four workers were trying to remove a grayloc clamp located on a gas lift line.

One of the four bolts was removed, and the other three were cut off when removing the clamp.

A worker knocked on the clamp with a brass hammer to free the connection.

A hydrocarbon release occurred (the fluid in production causing annulus).

Why did it happen?

Production casing valve on the wellhead was stuck.

- This limited workers’ ability to prove that there was no energy on the well-side of the gas lift choke.

Workers thought zero energy was demonstrated before starting work.

Isolation work and verification was not fully effective (revealed by investigation).

What did they learn?

Verify and recognise the production casing valve’s integrity.

Evaluate the knowledge of workers. Ensure they are trained and understand:

- Interfaces between surface and subsurface equipment

- Work management requirements for isolation control

- Independent verification of zero energy

Provide appropriate training if required.

Ask yourself or your crew

What should the workers have done differently?

What pre-use checks should you do before maintenance works on well gas lines?

How do you confirm production casing valve integrity? Why is that important?

What measures do we have in place to prevent this from happening on our site? How can we improve?

A hydrocarbon release occurred during removal of a clamp connector on a well gas lift flow line. No personnel were injured.