-

What happened?

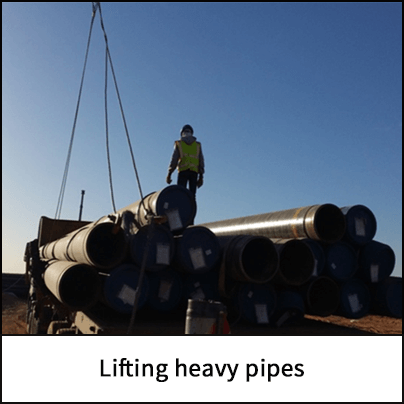

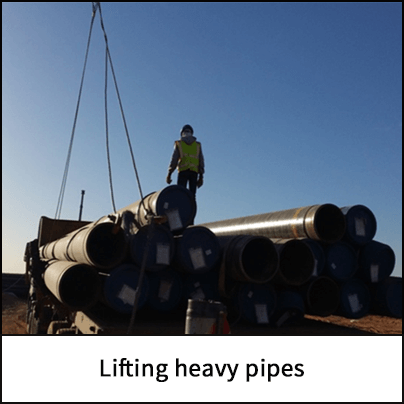

While unloading pipes from a truck trailer, worker A was at the rear of the trailer securing the load for lifting.

At the same time, worker B was performing the same activity at the front of the trailer.

Worker B stepped down from the trailer and signalled the crane operator to begin lifting the load.

The load began to be lifted, with worker A unaware of this. When he realized, he jumped from the truck, injuring himself in the fall.

Worker A was transported to the nearest hospital with a broken ankle, requiring recovery time (lost days). This incident had potential for very serious personal injuries or death.

-

Why did it happen?

Competence:

- Lack of knowledge and training: the workers had little training and weren’t aware of the lifting plan and risks associated with their tasks.

Procedures and processes:

- Workers were positioned in the line of fire.

- The indications for lifting the load were not given by a signaler.

- The hazard identification was insufficient.

- There was no work permit for the task.

- The work authorization did not specify compliance with the requirements for safe work.

Equipment:

- There was no ladder at the rear the truck.

- There was no equipment to control the operation from the ground.

Planning:

- Insufficient consideration of human factors such as rushing to finish, heavy workload and fatigue.

- Deficient supervision of lifting/unloading operations. Decision to continue although the supervisor had left after finishing their workday.

-

What did they learn?

The lift team should comprise at a minimum of a manager, a supervisor, a signaller, a slinger or rigger of the lifted load, a lifting crane operator, and a technical authority.

Each lift requires a lifting plan as part of the work permit. Determine the requirements according to the type of lift, the degree of complexity, and the associated risks. Extend the permit when necessary and stop the work if the lift deviates from the plan.

Review and validate your area’s lifting procedure and keep it up-to-date. In the case of joint ventures (JV) or contractors, ensure there is a safe lifting operation procedure.

Have a checklist prior to beginning work. For non-routine activities, have a lift authority separate from the contractor.

Ensure sufficient supervision, adjusting it to operators’ level of training and risk. Supervisor should remain in the working area until the end of the activities.

Take into account factors such as fatigue, particularly at the end of the shifts or where you observe complacency. Avoid overtime and establish a protocol for this type of work.

Ensure that everyone who participates in the planning, execution, and maintenance of the lifting equipment is sufficiently trained and authorised (follow industry standards for defining the skills and training). Establish what is the minimum training for supervisors.

During planning, determine the critical activities, their authorisation, identify the hazards, and evaluate the risk. Pay special attention to non-routine operations, both simple and complex.

-

Ask yourself or your crew

How can we prevent something like this from happening here?

Who is in your lift team today, and what responsibilities do each one of you have? How do you know that everyone is sufficiently trained and has the skills to perform the job?

What should you do if you find yourself or observe a colleague positioned in the line of fire?

What changes should we make to the way we work to improve safety?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

While unloading pipes from a truck trailer, worker A was at the rear of the trailer securing the load for lifting.

At the same time, worker B was performing the same activity at the front of the trailer.

Worker B stepped down from the trailer and signalled the crane operator to begin lifting the load.

The load began to be lifted, with worker A unaware of this. When he realized, he jumped from the truck, injuring himself in the fall.

Worker A was transported to the nearest hospital with a broken ankle, requiring recovery time (lost days). This incident had potential for very serious personal injuries or death.

Why did it happen?

Competence:

- Lack of knowledge and training: the workers had little training and weren’t aware of the lifting plan and risks associated with their tasks.

Procedures and processes:

- Workers were positioned in the line of fire.

- The indications for lifting the load were not given by a signaler.

- The hazard identification was insufficient.

- There was no work permit for the task.

- The work authorization did not specify compliance with the requirements for safe work.

Equipment:

- There was no ladder at the rear the truck.

- There was no equipment to control the operation from the ground.

Planning:

- Insufficient consideration of human factors such as rushing to finish, heavy workload and fatigue.

- Deficient supervision of lifting/unloading operations. Decision to continue although the supervisor had left after finishing their workday.

What did they learn?

The lift team should comprise at a minimum of a manager, a supervisor, a signaller, a slinger or rigger of the lifted load, a lifting crane operator, and a technical authority.

Each lift requires a lifting plan as part of the work permit. Determine the requirements according to the type of lift, the degree of complexity, and the associated risks. Extend the permit when necessary and stop the work if the lift deviates from the plan.

Review and validate your area’s lifting procedure and keep it up-to-date. In the case of joint ventures (JV) or contractors, ensure there is a safe lifting operation procedure.

Have a checklist prior to beginning work. For non-routine activities, have a lift authority separate from the contractor.

Ensure sufficient supervision, adjusting it to operators’ level of training and risk. Supervisor should remain in the working area until the end of the activities.

Take into account factors such as fatigue, particularly at the end of the shifts or where you observe complacency. Avoid overtime and establish a protocol for this type of work.

Ensure that everyone who participates in the planning, execution, and maintenance of the lifting equipment is sufficiently trained and authorised (follow industry standards for defining the skills and training). Establish what is the minimum training for supervisors.

During planning, determine the critical activities, their authorisation, identify the hazards, and evaluate the risk. Pay special attention to non-routine operations, both simple and complex.

Ask yourself or your crew

How can we prevent something like this from happening here?

Who is in your lift team today, and what responsibilities do each one of you have? How do you know that everyone is sufficiently trained and has the skills to perform the job?

What should you do if you find yourself or observe a colleague positioned in the line of fire?

What changes should we make to the way we work to improve safety?

Two workers were unloading pipes from a truck trailer. One of them signalled the crane operator to begin lifting the load, with the second one being unaware of this. When he realised, he jumped out of the trailer and injured his ankle.