-

What happened?

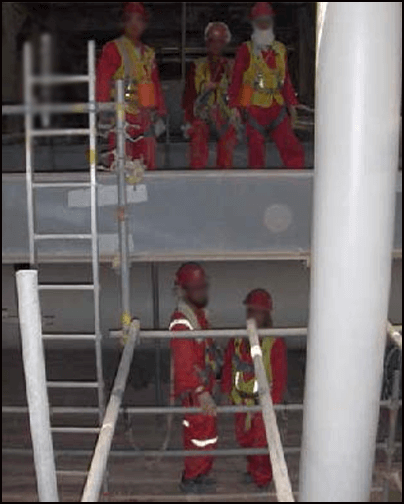

A scaffolding team were working in a ‘man chain’, passing materials down the scaffolding.

A 2 metre (6ft) wooden plank fell 6 metres (19 ft) down the man chain.

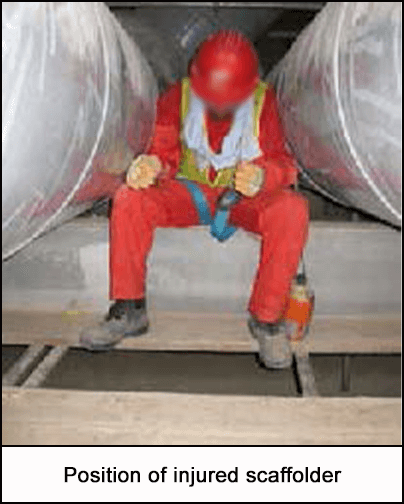

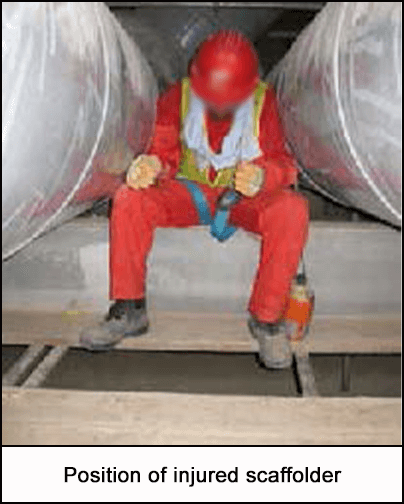

It hit a worker on their helmet, causing a 4cm (1.5 inch) laceration to their forehead and neck pain.

The scaffolder made a full recovery.

-

Why did it happen?

The crew were feeding equipment too quickly down the man chain.

There was no clear communication process for the materials being passed down the man chain (to confirm that the receiving person has taken control of the item that is being passed).

The method statement and job safety analysis were too generic (it did not address communication).

-

What did they learn?

Make sure that materials are only passed down a man chain as fast as they can be lowered safely.

Workers should use a clear system to indicate that the receiving person has accepted and has hold of the item. If noisy, non-verbal communication, such as twisting the item, can be used.

Make sure that all work method statements are specific to the task being carried out, including the need for communication.

Make sure that all workers are trained and competent to perform their duties.

Every task should be approached as if it were ‘new’, even if it is a routine job.

-

Ask yourself or your crew

Have you ever known anybody to be injured in a similar incident? What happened?

What procedures are in place at your worksite for safe descent of equipment via a man chain?

How will we communicate that the receiver has safely taken hold of an item in man chain?

Without the worker’s helmet, this incident would have been a lot more serious. Does everyone on your site have, and wear, the correct PPE?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A scaffolding team were working in a ‘man chain’, passing materials down the scaffolding.

A 2 metre (6ft) wooden plank fell 6 metres (19 ft) down the man chain.

It hit a worker on their helmet, causing a 4cm (1.5 inch) laceration to their forehead and neck pain.

The scaffolder made a full recovery.

Why did it happen?

The crew were feeding equipment too quickly down the man chain.

There was no clear communication process for the materials being passed down the man chain (to confirm that the receiving person has taken control of the item that is being passed).

The method statement and job safety analysis were too generic (it did not address communication).

What did they learn?

Make sure that materials are only passed down a man chain as fast as they can be lowered safely.

Workers should use a clear system to indicate that the receiving person has accepted and has hold of the item. If noisy, non-verbal communication, such as twisting the item, can be used.

Make sure that all work method statements are specific to the task being carried out, including the need for communication.

Make sure that all workers are trained and competent to perform their duties.

Every task should be approached as if it were ‘new’, even if it is a routine job.

Ask yourself or your crew

Have you ever known anybody to be injured in a similar incident? What happened?

What procedures are in place at your worksite for safe descent of equipment via a man chain?

How will we communicate that the receiver has safely taken hold of an item in man chain?

Without the worker’s helmet, this incident would have been a lot more serious. Does everyone on your site have, and wear, the correct PPE?

A scaffolding team were working in a man chain passing materials down the scaffolding. A wooden plank fell down the man chain, injuring a worker.