-

What happened?

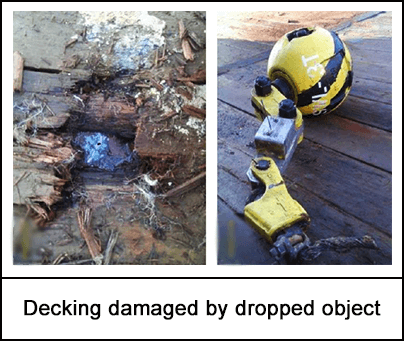

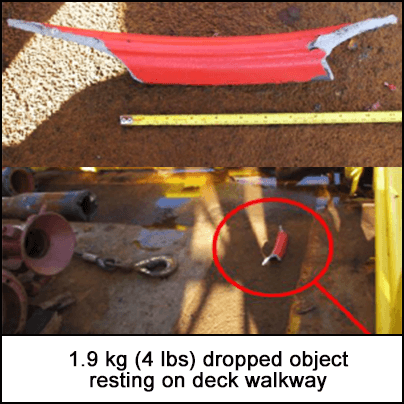

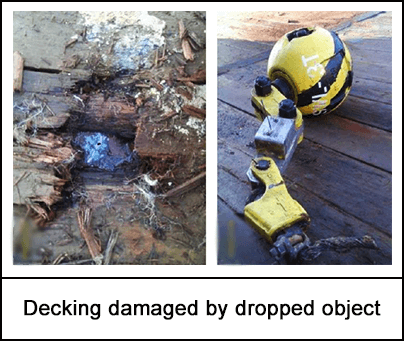

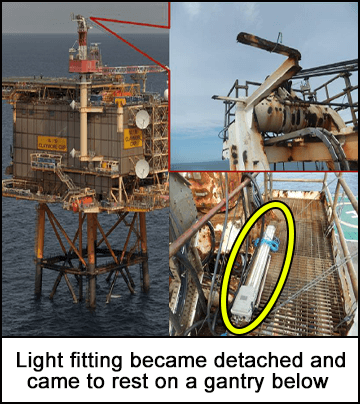

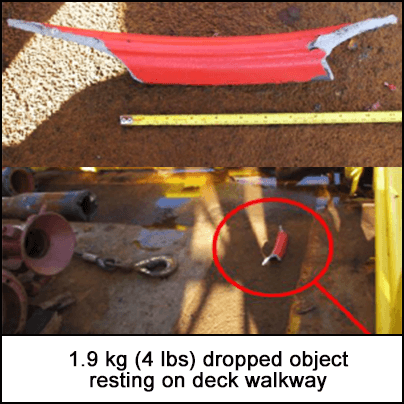

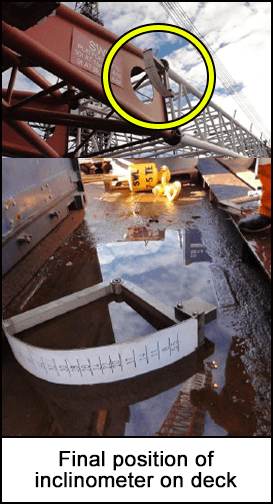

Serious injuries and fatalities occur regularly as a result of dropped objects when using cranes for lifting.

The number of dropped objects is very high and a common problem for those in the oil, gas and marine industries.

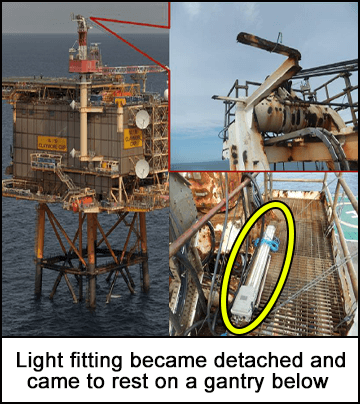

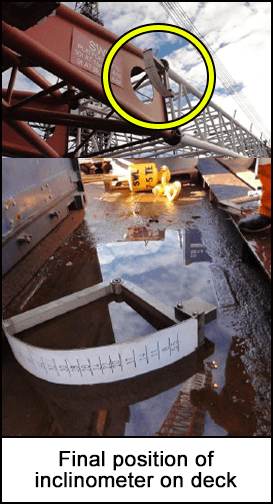

Some examples of dropped objects are parts of the crane, tools, floodlights, as well as the items being lifted.

-

Why did it happen?

The five top causes of dropped objects are:

- Inadequate securing (floodlights, tools and the loads).

- Poor hazard identification and risk assessment (lifting without adequate end stops, personnel working nearby, hatches left open).

- Inadequate maintenance (walkway kickplates missing, stored spares).

- Corrosion (end fixtures and fittings, handrails, gratings).

- Failed fixtures and fittings (redundant crane parts, old scaffolding shelving).

-

What did they learn?

Ensure all tools, equipment and materials are secured.

Take measures to prevent dropped objects when working at height or over grating.

Erect barriers over drop zones below worksites.

Remove all tools, equipment and materials from worksites when work is completed.

Have an independent advisor inspect structures and equipment at risk of falling.

Use the DROPS scheme to help eliminate damage to people, structures and equipment.

-

Ask yourself or your crew

How can a dropped object happen here, during our lifting operation?

How do we know the load is secure?

What hazards have we identified? Have we missed any?

How do we know the crane and other equipment has been properly maintained?

Can you spot any corrosion?

How would you report something that needed attention?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

Serious injuries and fatalities occur regularly as a result of dropped objects when using cranes for lifting.

The number of dropped objects is very high and a common problem for those in the oil, gas and marine industries.

Some examples of dropped objects are parts of the crane, tools, floodlights, as well as the items being lifted.

Why did it happen?

The five top causes of dropped objects are:

- Inadequate securing (floodlights, tools and the loads).

- Poor hazard identification and risk assessment (lifting without adequate end stops, personnel working nearby, hatches left open).

- Inadequate maintenance (walkway kickplates missing, stored spares).

- Corrosion (end fixtures and fittings, handrails, gratings).

- Failed fixtures and fittings (redundant crane parts, old scaffolding shelving).

What did they learn?

Ensure all tools, equipment and materials are secured.

Take measures to prevent dropped objects when working at height or over grating.

Erect barriers over drop zones below worksites.

Remove all tools, equipment and materials from worksites when work is completed.

Have an independent advisor inspect structures and equipment at risk of falling.

Use the DROPS scheme to help eliminate damage to people, structures and equipment.

Ask yourself or your crew

How can a dropped object happen here, during our lifting operation?

How do we know the load is secure?

What hazards have we identified? Have we missed any?

How do we know the crane and other equipment has been properly maintained?

Can you spot any corrosion?

How would you report something that needed attention?

Serious injuries and fatalities occur regularly as a result of dropped objects when using cranes for lifting.