-

What happened?

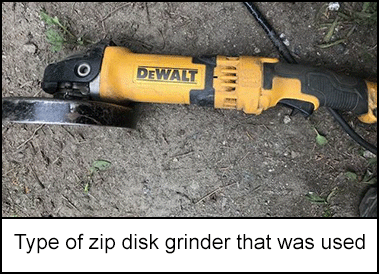

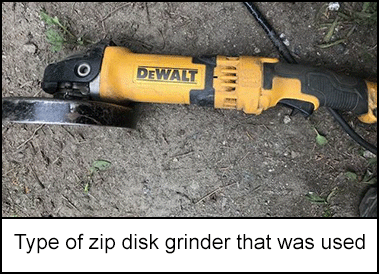

A welder’s thumb was injured when the blade of zip disk grinder made contact while cutting a piece of 1/8 inch metal plate.

The worker had one hand on the handle of the grinder and the other hand on the metal plate. The plate began to heat up making it warp and bind, which caused the zip disk to shift forward. The disk then contacted the back of the welder’s thumb, resulting in a serious laceration.

-

Why did it happen?

- Worker’s hand was in the line of fire.

- The plate was not secured (e.g. in a vice).

- Grinder should have had a side handle.

Contributing factors:

- The use of a straight handle-style tool is a contributing factor. The manufacturers specifications state that a side handle should be used if the grinder comes with one. The worker may have had better positioning and control of tool with a side handle.

-

What did they learn?

- The company re-enforced the importance of body positioning during job set up with all the crew members, including coaching the supervisors to take time to assess.

- Enforce the use of both hands on the grinder when using buffing, grinding and cutting disks.

- Work with manufacturer to determine appropriate handle style for operations.

-

Ask yourself or your crew

How can we prevent something like this from happening here?

What are other risks are associated with forklift operations? How can you mitigate those risks at your work site?

What safety recommendations should be included in the operational instructions?

How can we, as a company, implement a practical training plan that focuses on the job position, and make sure pedestrians are safer from forklifts in the future?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A welder’s thumb was injured when the blade of zip disk grinder made contact while cutting a piece of 1/8 inch metal plate.

The worker had one hand on the handle of the grinder and the other hand on the metal plate. The plate began to heat up making it warp and bind, which caused the zip disk to shift forward. The disk then contacted the back of the welder’s thumb, resulting in a serious laceration.

Why did it happen?

- Worker’s hand was in the line of fire.

- The plate was not secured (e.g. in a vice).

- Grinder should have had a side handle.

Contributing factors:

- The use of a straight handle-style tool is a contributing factor. The manufacturers specifications state that a side handle should be used if the grinder comes with one. The worker may have had better positioning and control of tool with a side handle.

What did they learn?

- The company re-enforced the importance of body positioning during job set up with all the crew members, including coaching the supervisors to take time to assess.

- Enforce the use of both hands on the grinder when using buffing, grinding and cutting disks.

- Work with manufacturer to determine appropriate handle style for operations.

Ask yourself or your crew

How can we prevent something like this from happening here?

What are other risks are associated with forklift operations? How can you mitigate those risks at your work site?

What safety recommendations should be included in the operational instructions?

How can we, as a company, implement a practical training plan that focuses on the job position, and make sure pedestrians are safer from forklifts in the future?

A welder’s thumb was injured when the blade of zip disk grinder made contact while cutting a piece of metal plate. The plate began to heat up making it warp and bind, which caused the zip disk to shift forward. The disk then contacted the back of the welder’s thumb, resulting in a serious laceration.

Original material courtesy of Energy Safety Canada

Additional resources:

ACSA Cut Off Disk & Zip Disk Safety, watch video