-

What happened?

A well service crew was swabbing when the swab assembly reached the top of the well and parted the sand line.

The rig manager was manually spooling the last six wraps of the sand line and became entangled in the parted line.

The driller reacted, moving the throttle in the wrong direction and energized the line, which cinched on the rig manager’s leg.

The rig manager was launched into the raising ram of the service rig and sustained a leg amputation and other serious injuries.

-

Why did it happen?

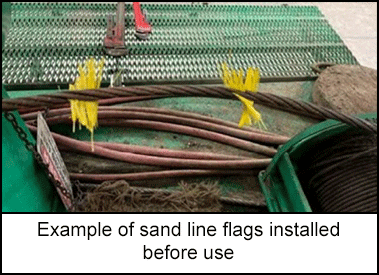

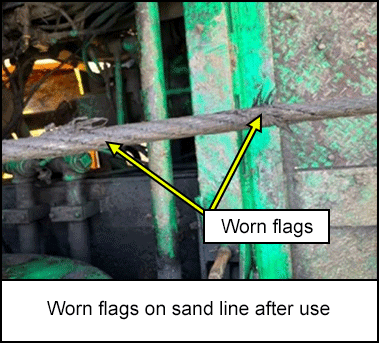

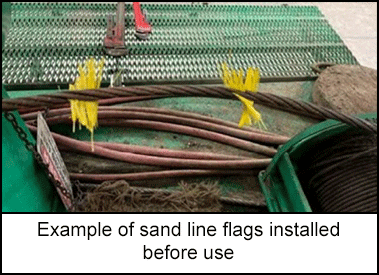

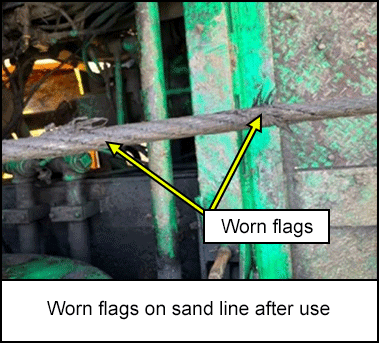

- Several sets of flags, 3-2-1, in use and visible on the second swab were no longer visible on the third swab of this horizontal well.

- Personnel did not recognize how close the swab assembly was to the surface (at the top of the lubricator) because of sun in their eyes, multitasking and other distractions.

- The throttle control configuration on this rig operates in the opposite direction of the typical driller’s draw works controls. During this high stress moment, the driller activated the throttle control in the wrong direction.

-

What did they learn?

- Ensure flags are designed to withstand the conditions of the well they are being used for.

- Investigate the use of fail-safe measures so the swabbing assembly is not pulled up too far, even if flags become worn/not visible or an error or mistake is made (i.e., ensure there is capacity to fail safely).

- Review control configurations to ensure they are consistent.

- Review the incident and job safety analysis (JSA) with all operations personnel prior to swabbing.

- Prior to conducting swabbing operations, the rig manager must get approval from the field superintendent to ensure safeguards are in place and everyone understands their roles and responsibilities.

-

Ask yourself or your crew

- How can something like this happen here (e.g. on our site)?

- What safety measures (i.e. procedures, controls/barriers) do we have in place to mitigate the risk?

- How do we know the risk controls/barriers are working?

- What improvements or changes should we make to the procedures, controls/barriers or the way we work?

Add to homescreen

If you want to add this app to home screen tap and then ‘Add to Home Screen’.

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A well service crew was swabbing when the swab assembly reached the top of the well and parted the sand line.

The rig manager was manually spooling the last six wraps of the sand line and became entangled in the parted line.

The driller reacted, moving the throttle in the wrong direction and energized the line, which cinched on the rig manager’s leg.

The rig manager was launched into the raising ram of the service rig and sustained a leg amputation and other serious injuries.

Why did it happen?

- Several sets of flags, 3-2-1, in use and visible on the second swab were no longer visible on the third swab of this horizontal well.

- Personnel did not recognize how close the swab assembly was to the surface (at the top of the lubricator) because of sun in their eyes, multitasking and other distractions.

- The throttle control configuration on this rig operates in the opposite direction of the typical driller’s draw works controls. During this high stress moment, the driller activated the throttle control in the wrong direction.

What did they learn?

- Ensure flags are designed to withstand the conditions of the well they are being used for.

- Investigate the use of fail-safe measures so the swabbing assembly is not pulled up too far, even if flags become worn/not visible or an error or mistake is made (i.e., ensure there is capacity to fail safely).

- Review control configurations to ensure they are consistent.

- Review the incident and job safety analysis (JSA) with all operations personnel prior to swabbing.

- Prior to conducting swabbing operations, the rig manager must get approval from the field superintendent to ensure safeguards are in place and everyone understands their roles and responsibilities.

Ask yourself or your crew

- How can something like this happen here (e.g. on our site)?

- What safety measures (i.e. procedures, controls/barriers) do we have in place to mitigate the risk?

- How do we know the risk controls/barriers are working?

- What improvements or changes should we make to the procedures, controls/barriers or the way we work?

Published on 04/05/23

1714 Views

A well service crew was swabbing when the swab assembly reached the top of the well and parted the sand line. The rig manager was manually spooling in the last six wraps of the sand line and became entangled in the parted line. The driller reacted, moving the throttle in the wrong direction and energized the line, which cinched on the rig manager’s leg. The rig manager was launched into the raising ram of the service rig sustained a leg amputation and other serious injuries.

Original material courtesy of Energy Safety Canada

Other resources:

Life Saving Rules

Building Capacity to Manage Pressure Program

Fit for Duty Guideline