-

What happened?

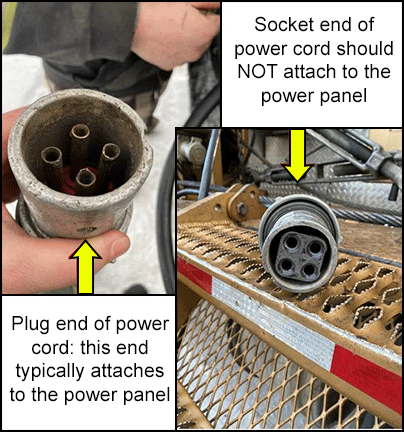

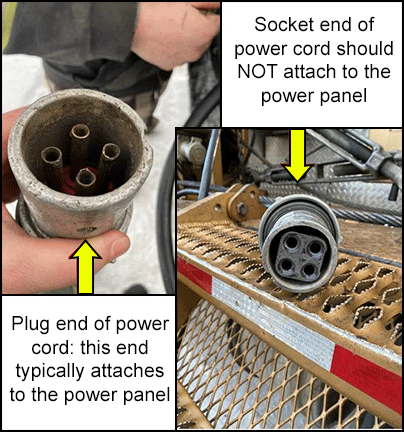

A rig crew was in the process of rigging out. One worker verified that the plug (“male”) end of a 240- volt power cord was not connected and placed the cord alongside the pipe rack.

NOTE: Like a household power cord, the plug is the end that would normally be inserted into the electrical outlet, or panel, for power. Unbeknownst to these workers, this electrical panel had the opposite configuration, and the socket (female) end of the cord was still attached to the power panel.

Another worker was instructed to wrap up the power cord and was collecting it from under the pipe rack when it became stuck. While trying to grab the end of the cord to free it, the worker’s fingers touched the exposed plug end posts and received an electric shock resulting in severe and prolonged muscle spasms.

-

Why did it happen?

- The rig’s power panel had a connection for a socket end, which is contrary to the typical configuration. When the worker confirmed the plug end was not connected to the panel, it was incorrectly assumed that the cord was not energized.

- No one confirmed isolation of power by removing the cord from the rig’s power panel.

- The exposed posts on the plug end allowed the worker to inadvertently touch the energized components.

- The job safety analysis (JSA) that was reviewed had not been approved and did not identify the hazards or proper controls for unplugging and handling power cords.

-

What did they learn?

- All power panels must be configured to receive/connect with plug ends.

- Power cords must be locked into place and controlled by the rig manager when live. The rig manager is responsible to ensure the system is de-energized before unplugging.

- Personnel must access JSAs from the central system to ensure the most recent and approved version is in use.

-

Ask yourself or your crew

- How can something like this happen here (e.g. on our site)?

- What safety measures (i.e. procedures, controls/barriers) do we have in place to mitigate the risk?

- How do we know the risk controls/barriers are working?

- What improvements or changes should we make to the procedures, controls/barriers or the way we work?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A rig crew was in the process of rigging out. One worker verified that the plug (“male”) end of a 240- volt power cord was not connected and placed the cord alongside the pipe rack.

NOTE: Like a household power cord, the plug is the end that would normally be inserted into the electrical outlet, or panel, for power. Unbeknownst to these workers, this electrical panel had the opposite configuration, and the socket (female) end of the cord was still attached to the power panel.

Another worker was instructed to wrap up the power cord and was collecting it from under the pipe rack when it became stuck. While trying to grab the end of the cord to free it, the worker’s fingers touched the exposed plug end posts and received an electric shock resulting in severe and prolonged muscle spasms.

Why did it happen?

- The rig’s power panel had a connection for a socket end, which is contrary to the typical configuration. When the worker confirmed the plug end was not connected to the panel, it was incorrectly assumed that the cord was not energized.

- No one confirmed isolation of power by removing the cord from the rig’s power panel.

- The exposed posts on the plug end allowed the worker to inadvertently touch the energized components.

- The job safety analysis (JSA) that was reviewed had not been approved and did not identify the hazards or proper controls for unplugging and handling power cords.

What did they learn?

- All power panels must be configured to receive/connect with plug ends.

- Power cords must be locked into place and controlled by the rig manager when live. The rig manager is responsible to ensure the system is de-energized before unplugging.

- Personnel must access JSAs from the central system to ensure the most recent and approved version is in use.

Ask yourself or your crew

- How can something like this happen here (e.g. on our site)?

- What safety measures (i.e. procedures, controls/barriers) do we have in place to mitigate the risk?

- How do we know the risk controls/barriers are working?

- What improvements or changes should we make to the procedures, controls/barriers or the way we work?

A rig crew was in the process of rigging out. One worker verified that the plug end of a 240-volt power cord was not connected and place the cord alongside the pipe rack. Another worker was instructed to wrap up the power cord and was collecting it from under the pipe rack when it became stuck. While trying to grab the end of the cord to free it, the worker’s fingers touched the exposed plug end posts and received an electric shock resulting in sever and prolonged muscle spasms.

Original material courtesy of Energy Safety Canada

Other industry resources:

Video - Energy Isolation

Life Saving Rules

Safety Critical Procedures Safety Bulletin

Canadian Electrical Code