-

What happened?

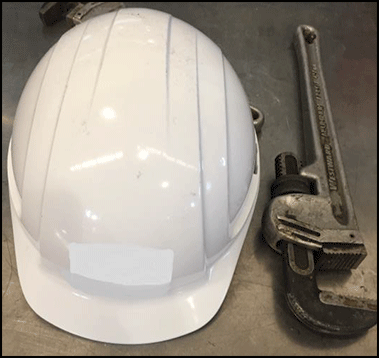

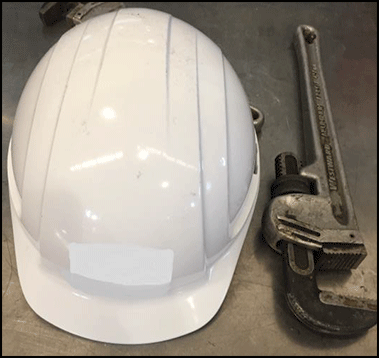

A worker was struck in the chest by a pipe wrench and sustained six broken ribs and a

damaged spleen. The impacted worker was a contracted fishing operator, or “fisherman”, on a service rig.The fisherman was on the rig floor while waiting for the service rig crew to complete their tasks.

A service rig crew member removed the last drill collar and installed a lift sub using a pipe wrench. A worker installed the sub and fisherman then operated the power tongs to allow the tightening of the lift sub’s remaining threads.

At the same time, another crew member released winch controls, which redirected all hydraulic power to the power tongs and revved the engine.

The extra engine capacity in the power tongs spun the equipment and attached pipe wrench into the fisherman. The impact threw the fisherman several feet, he was immediately transported to the hospital.

-

Why did it happen?

A pipe wrench was left on the lift sub while power tongs were being operated, and the re-direction of all hydraulic power to power tongs when the engine revved.

Contributing factors:

- Unable to disable hydraulic power to power tongs due to rig design.

- Fisherman operated the equipment while not formally authorized.

- Incomplete risk assessment highlighting potential hazards and outcomes.

-

What did they learn?

- Communicate any equipment energy hazards (potential hydraulic power issues) to workers on site.

- Formal turnover and authority procedures should be in place and used.

- Ensure no third party workers are in the area until control of authority has been transferred.

- Companies could inventory all their equipment where the hydraulic power hazards remain and determine whether or not feasible to retrofit.

-

Ask yourself or your crew

- How can something like this happen here (e.g. on our site)?

- What safety measures (i.e. procedures, controls/barriers) do we have in place to mitigate the risk?

- How do we know the risk controls/barriers are working?

- What improvements or changes should we make to the procedures, controls/barriers or the way we work?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A worker was struck in the chest by a pipe wrench and sustained six broken ribs and a

damaged spleen. The impacted worker was a contracted fishing operator, or “fisherman”, on a service rig.

The fisherman was on the rig floor while waiting for the service rig crew to complete their tasks.

A service rig crew member removed the last drill collar and installed a lift sub using a pipe wrench. A worker installed the sub and fisherman then operated the power tongs to allow the tightening of the lift sub’s remaining threads.

At the same time, another crew member released winch controls, which redirected all hydraulic power to the power tongs and revved the engine.

The extra engine capacity in the power tongs spun the equipment and attached pipe wrench into the fisherman. The impact threw the fisherman several feet, he was immediately transported to the hospital.

Why did it happen?

A pipe wrench was left on the lift sub while power tongs were being operated, and the re-direction of all hydraulic power to power tongs when the engine revved.

Contributing factors:

- Unable to disable hydraulic power to power tongs due to rig design.

- Fisherman operated the equipment while not formally authorized.

- Incomplete risk assessment highlighting potential hazards and outcomes.

What did they learn?

- Communicate any equipment energy hazards (potential hydraulic power issues) to workers on site.

- Formal turnover and authority procedures should be in place and used.

- Ensure no third party workers are in the area until control of authority has been transferred.

- Companies could inventory all their equipment where the hydraulic power hazards remain and determine whether or not feasible to retrofit.

Ask yourself or your crew

- How can something like this happen here (e.g. on our site)?

- What safety measures (i.e. procedures, controls/barriers) do we have in place to mitigate the risk?

- How do we know the risk controls/barriers are working?

- What improvements or changes should we make to the procedures, controls/barriers or the way we work?

On a service rig, a fishing operator was struck in the chest by a pipe wrench, sustaining six broken ribs and a damaged spleen. The cause of the incident was a pipe wrench being left on the lift sub while power tongs were being operated, combined with the redirection of all hydraulic power to the power tongs when the engine revved.

Original material courtesy of Energy Safety Canada