-

What happened?

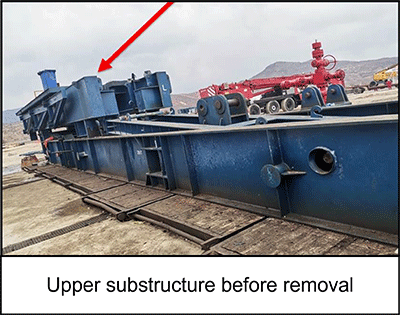

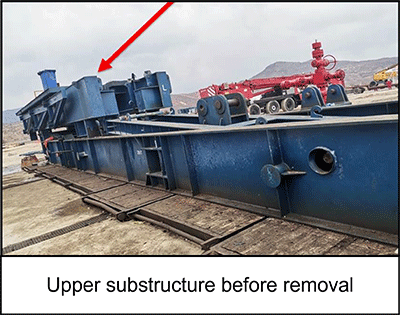

An operation was underway to rig down the substructure of a drilling rig by removing the securing pins and disassembling two parts of the substructure.

The crew was waiting on trucks and was in the process of repositioning cranes in preparation to rig up the crane and disassemble the substructure by removing the pins.

The upper substructure was still in place, so no crane could be hooked up to the support leg to take the 5 tons of weight.

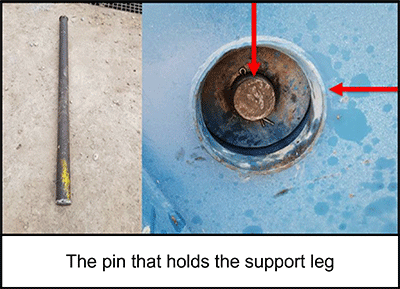

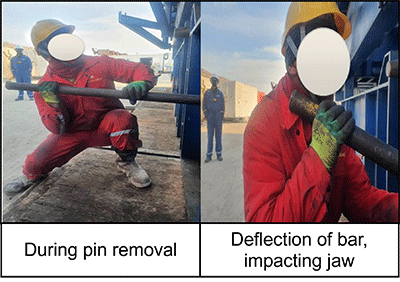

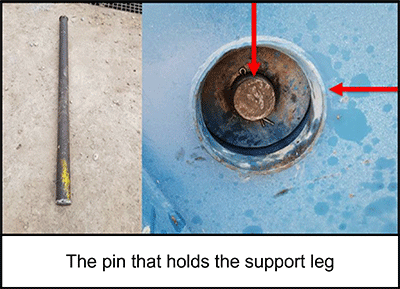

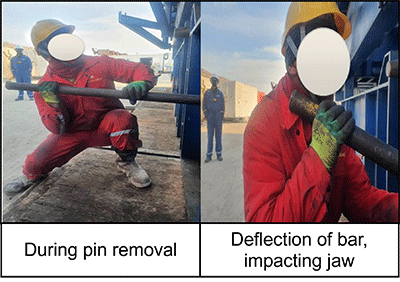

A drift bar was used to remove one of the pins of the support leg. The derrickman removed one pin, as instructed by the driller. This is not normal procedure on this rig but was not detailed in the standard operating procedure (SOP). This had no effect on the support leg because the pin on the other side was still holding the full weight of the support leg.

The injured person (IP) watched them remove the pin. He took the drift bar to the other side of the substructure and began striking the second pin. He had not been instructed to remove this second pin as work was suspended to wait for a crane to come and hook on to the support leg to take the weight.

When he knocked the pin entirely through the pivot point of the support leg, the weight of the leg dropped onto the bar and caused it to deflect 20cm (7 inches), fracturing the IP’s jaw.

-

Why did it happen?

The SOP did not clearly state that the leg should be supported before removing the pins. There was a lack of cohesion between the SOP, job safety analysis (JSA) and lifting plan regarding the sequence of works.

Written procedures are vital in maintaining consistency and in ensuring that everyone has the same basic level of information, which was not the case in this instance.

Equally essential is the requirement to implement processes for communicating job related risks, hazards and control measures to employees and contractors as detailed within permits, risk assessments and job safety analysis, which was neglected and lead to this incident occurring.

-

What did they learn?

Review the substructure SOPs and ensure that they are relevant to the contractor crew of the rig, and clearly state that pins shall only be removed on the lower substructure with the crane is in place.

Ensure that the lifting plan for the lower substructure clearly covers supporting the load before removing pins.

Communicate the incident in safety meetings to emphasise the importance of following instructions and checking with supervisors before starting any new tasks.

Implement a line of fire safety campaign covering a line of fire and heavy impact tools utilised during rig site operations.

-

Ask yourself or your crew

What factors might cause this type of incident happening here? Consider communications, and a ‘can do’ attitude.

How can we improve communication during this type of task?

What would you have done if you saw someone doing this?

Think about today’s operation: what parts of the procedure are unclear?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

An operation was underway to rig down the substructure of a drilling rig by removing the securing pins and disassembling two parts of the substructure.

The crew was waiting on trucks and was in the process of repositioning cranes in preparation to rig up the crane and disassemble the substructure by removing the pins.

The upper substructure was still in place, so no crane could be hooked up to the support leg to take the 5 tons of weight.

A drift bar was used to remove one of the pins of the support leg. The derrickman removed one pin, as instructed by the driller. This is not normal procedure on this rig but was not detailed in the standard operating procedure (SOP). This had no effect on the support leg because the pin on the other side was still holding the full weight of the support leg.

The injured person (IP) watched them remove the pin. He took the drift bar to the other side of the substructure and began striking the second pin. He had not been instructed to remove this second pin as work was suspended to wait for a crane to come and hook on to the support leg to take the weight.

When he knocked the pin entirely through the pivot point of the support leg, the weight of the leg dropped onto the bar and caused it to deflect 20cm (7 inches), fracturing the IP’s jaw.

Why did it happen?

The SOP did not clearly state that the leg should be supported before removing the pins. There was a lack of cohesion between the SOP, job safety analysis (JSA) and lifting plan regarding the sequence of works.

Written procedures are vital in maintaining consistency and in ensuring that everyone has the same basic level of information, which was not the case in this instance.

Equally essential is the requirement to implement processes for communicating job related risks, hazards and control measures to employees and contractors as detailed within permits, risk assessments and job safety analysis, which was neglected and lead to this incident occurring.

What did they learn?

Review the substructure SOPs and ensure that they are relevant to the contractor crew of the rig, and clearly state that pins shall only be removed on the lower substructure with the crane is in place.

Ensure that the lifting plan for the lower substructure clearly covers supporting the load before removing pins.

Communicate the incident in safety meetings to emphasise the importance of following instructions and checking with supervisors before starting any new tasks.

Implement a line of fire safety campaign covering a line of fire and heavy impact tools utilised during rig site operations.

Ask yourself or your crew

What factors might cause this type of incident happening here? Consider communications, and a ‘can do’ attitude.

How can we improve communication during this type of task?

What would you have done if you saw someone doing this?

Think about today’s operation: what parts of the procedure are unclear?

A worker removed a securing pin without being instructed to do so, leading to a 5 ton (5080kg) support leg dropping onto the drift bar, which deflected towards the worker and fractured his jaw.