-

What happened?

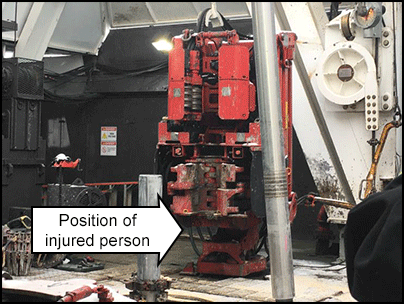

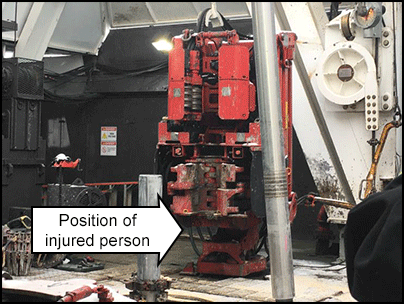

A rig crew was making up the bottom-hole assembly (BHA) with a third-party worker.

The iron roughneck was inadvertently activated from the doghouse, extending it forward and pinning the third-party worker against the stump.

The rig crew activated the emergency stop and the iron roughneck was retracted, releasing the injured person. The onsite medic assessed the injured person who had sustained a hairline fracture at the pelvis and a contusion to the leg. The worker was taken to the hospital.

-

Why did it happen?

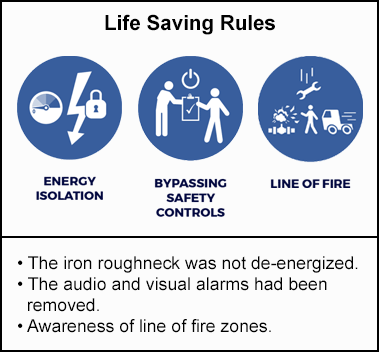

- The worker hit the sequence button and inadvertently activated the iron roughneck.

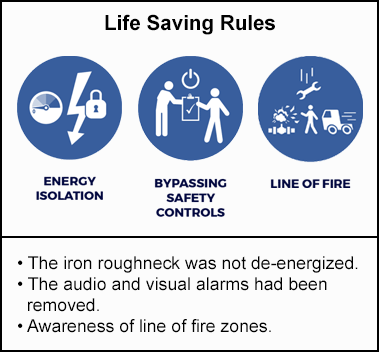

- The iron roughneck had not been de-energized when not in use.

- Manufacturer-supplied visual and audible safeguards were not installed on this piece of equipment.

-

What did they learn?

The iron roughneck had been moved from another rig, and the warning light and alarm had been removed for transport but not re-installed.

The iron roughneck was inadvertently activated with the ‘sequence’ button, which is seldom used. Safety meeting was held to review the job safety analysis (JSA) for handling BHA and the exclusion zone was reviewed.

An additional safety meeting was held, including the third-party worker, to review the tool-specific JSA.

The following measures/recommendations were taken:

- The ‘Sequence button’ has been disabled to prevent it from activating the iron roughneck. Operation is now only done from the rig-floor controls.

- A beacon light and audible alarm have been installed to indicate when the iron roughneck is operating.

- Inspection procedures are being updated to include function testing the iron roughneck’s audible and

visual alarms. - The JSAs’s are being updated to verify the iron roughneck is isolated during activities it is not

required for (e.g. handling BHA, running casing, drilling ahead, etc.). - Line of fire area between the iron roughneck and the stump is highlighted with high visibility

matting. - All parties must be present for the safety meeting to review the relevant JSA(s).

-

Ask yourself or your crew

- How can something like this happen here (e.g. on our site)?

- What safety measures (i.e. procedures, controls/barriers) do we have in place to mitigate the risk?

- How do we know the risk controls/barriers are working?

- What improvements or changes should we make to the procedures, controls/barriers or the way we work?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A rig crew was making up the bottom-hole assembly (BHA) with a third-party worker.

The iron roughneck was inadvertently activated from the doghouse, extending it forward and pinning the third-party worker against the stump.

The rig crew activated the emergency stop and the iron roughneck was retracted, releasing the injured person. The onsite medic assessed the injured person who had sustained a hairline fracture at the pelvis and a contusion to the leg. The worker was taken to the hospital.

Why did it happen?

- The worker hit the sequence button and inadvertently activated the iron roughneck.

- The iron roughneck had not been de-energized when not in use.

- Manufacturer-supplied visual and audible safeguards were not installed on this piece of equipment.

What did they learn?

The iron roughneck had been moved from another rig, and the warning light and alarm had been removed for transport but not re-installed.

The iron roughneck was inadvertently activated with the ‘sequence’ button, which is seldom used. Safety meeting was held to review the job safety analysis (JSA) for handling BHA and the exclusion zone was reviewed.

An additional safety meeting was held, including the third-party worker, to review the tool-specific JSA.

The following measures/recommendations were taken:

- The ‘Sequence button’ has been disabled to prevent it from activating the iron roughneck. Operation is now only done from the rig-floor controls.

- A beacon light and audible alarm have been installed to indicate when the iron roughneck is operating.

- Inspection procedures are being updated to include function testing the iron roughneck’s audible and

visual alarms. - The JSAs’s are being updated to verify the iron roughneck is isolated during activities it is not

required for (e.g. handling BHA, running casing, drilling ahead, etc.). - Line of fire area between the iron roughneck and the stump is highlighted with high visibility

matting. - All parties must be present for the safety meeting to review the relevant JSA(s).

Ask yourself or your crew

- How can something like this happen here (e.g. on our site)?

- What safety measures (i.e. procedures, controls/barriers) do we have in place to mitigate the risk?

- How do we know the risk controls/barriers are working?

- What improvements or changes should we make to the procedures, controls/barriers or the way we work?

A rig crew was making up the bottom-hole assembly with a third-party worker. The iron roughneck was inadvertently activated, extending it forward and pinning the third-party worker against the stump. The emergency stop was activated, and the iron roughneck was retracted, releasing the injured person who had sustained a hairline fracture at the pelvis and a contusion to the leg.