-

What happened?

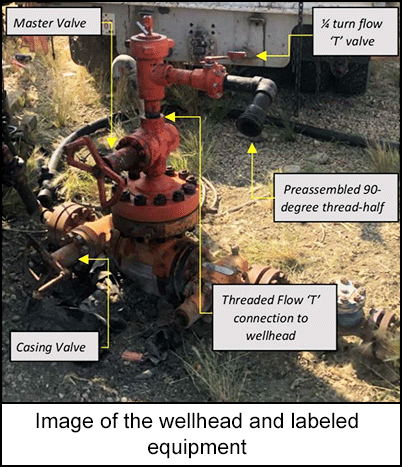

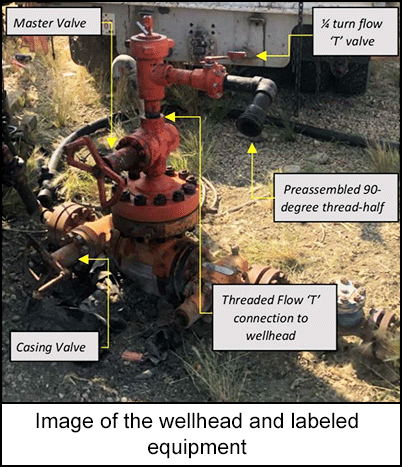

A worker was injured when a sudden release of wellbore pressure caused the disconnection of the flow ‘T’ from the wellhead.

A rig crew was on location to begin abandonment of an orphaned well. The task required the rig manager to check and record the shut-in wellhead pressure. The crew heard a hissing sound and observed the rig manager rotating on top of the flow ‘T’, until the flow 'T' disconnected from the wellhead master valve. The rig manager was taken to hospital with multiple head lacerations.

-

Why did it happen?

- Often, historical information is unavailable for orphaned wells.

- Sudden release of wellbore pressure through the 90 degree thread created enough force in the counter-clockwise direction to disconnect the flow 'T' from the wellhead master valve.

- The rig manager, who did not recall any of the event, was positioned in the line of fire.

-

What did they learn?

- The use of a 90-degree elbow with thread-half on the flow ‘T’ should be avoided. Equipment should be connected and oriented to account for the potential of pressure.

- Do not assume that wellhead components are in good working order, including valve function, valve orientation, and that component connections are secure.

- Prior to checking pressures, verify orientation of wellhead master valve (in the closed position) and orientation of valves above the master valve are closed.

- No work to be performed on wellhead components above the master valve, unless master valve is closed, and trapped pressure is bled off.

- Verification of wellbore pressure must be performed prior to connecting components to the flow ‘T’ ¼ turn valve.

-

Ask yourself or your crew

- How can something like this happen here (e.g. on our site)?

- What safety measures (i.e. procedures, controls/barriers) do we have in place to mitigate the risk?

- How do we know the risk controls/barriers are working?

- What improvements or changes should we make to the procedures, controls/barriers or the way we work?

Add to homescreen

If you want to add this app to home screen tap and then ‘Add to Home Screen’.

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A worker was injured when a sudden release of wellbore pressure caused the disconnection of the flow ‘T’ from the wellhead.

A rig crew was on location to begin abandonment of an orphaned well. The task required the rig manager to check and record the shut-in wellhead pressure. The crew heard a hissing sound and observed the rig manager rotating on top of the flow ‘T’, until the flow 'T' disconnected from the wellhead master valve. The rig manager was taken to hospital with multiple head lacerations.

Why did it happen?

- Often, historical information is unavailable for orphaned wells.

- Sudden release of wellbore pressure through the 90 degree thread created enough force in the counter-clockwise direction to disconnect the flow 'T' from the wellhead master valve.

- The rig manager, who did not recall any of the event, was positioned in the line of fire.

What did they learn?

- The use of a 90-degree elbow with thread-half on the flow ‘T’ should be avoided. Equipment should be connected and oriented to account for the potential of pressure.

- Do not assume that wellhead components are in good working order, including valve function, valve orientation, and that component connections are secure.

- Prior to checking pressures, verify orientation of wellhead master valve (in the closed position) and orientation of valves above the master valve are closed.

- No work to be performed on wellhead components above the master valve, unless master valve is closed, and trapped pressure is bled off.

- Verification of wellbore pressure must be performed prior to connecting components to the flow ‘T’ ¼ turn valve.

Ask yourself or your crew

- How can something like this happen here (e.g. on our site)?

- What safety measures (i.e. procedures, controls/barriers) do we have in place to mitigate the risk?

- How do we know the risk controls/barriers are working?

- What improvements or changes should we make to the procedures, controls/barriers or the way we work?

Published on 31/05/23

1332 Views

A worker was injured when a sudden release of wellbore pressure caused the disconnection of the flow of ‘T’ from the wellhead. The task required the worker to check and record the shut-in wellhead pressure however the crew heard a hissing sound and then the ‘T’ disconnected from the wellhead master valve. The worker was taken to hospital with multiple head lacerations.

Original material courtesy of Energy Safety Canada