-

What happened?

A portable fire water monitor was set up on night shift to provide coverage for a fixed firewater system which was about to be isolated.

During testing of the portable monitor, the unit separated under full system pressure.

The top section of the unit struck an operator in the upper chest, requiring first aid treatment.

-

Why did it happen?

The fire water monitor had not been left in a state that was ready to operate.

Although the operator performed rudimentary checks prior to use, they failed to identify that the spring loaded locking pins were not fully engaged.

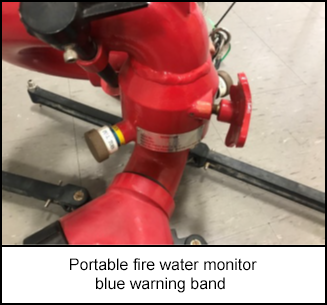

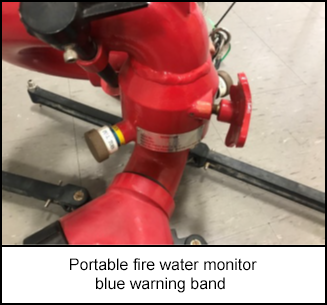

The width of the blue warning band on the fire water monitor’s spring loaded locking pins reduced when partially engaged. Therefore the warning band was not easily visible to the operator. This was worsened by the work occurring at night time.

The fire water monitor separated under full pressure. The operator was in the line of fire when separation occurred.

-

What did they learn?

Ensure personnel are adequately trained to operate fire suppression equipment that is not frequently used. Conduct adequate checks prior to use.

Fire suppression equipment must be left in a state that is ready to operate. Tag out any equipment that is not ready to operate.

Body positioning and line of fire risks should be considered when working with pressurised fire suppression systems.

-

Ask yourself or your crew

Do you have any fire suppression equipment that is not frequently used at your work site? Are you involved in using or testing this equipment?

Is all your emergency response equipment left in a ready state or tagged out accordingly?

Are line of fire exposures identified during routine operations tasks?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A portable fire water monitor was set up on night shift to provide coverage for a fixed firewater system which was about to be isolated.

During testing of the portable monitor, the unit separated under full system pressure.

The top section of the unit struck an operator in the upper chest, requiring first aid treatment.

Why did it happen?

The fire water monitor had not been left in a state that was ready to operate.

Although the operator performed rudimentary checks prior to use, they failed to identify that the spring loaded locking pins were not fully engaged.

The width of the blue warning band on the fire water monitor’s spring loaded locking pins reduced when partially engaged. Therefore the warning band was not easily visible to the operator. This was worsened by the work occurring at night time.

The fire water monitor separated under full pressure. The operator was in the line of fire when separation occurred.

What did they learn?

Ensure personnel are adequately trained to operate fire suppression equipment that is not frequently used. Conduct adequate checks prior to use.

Fire suppression equipment must be left in a state that is ready to operate. Tag out any equipment that is not ready to operate.

Body positioning and line of fire risks should be considered when working with pressurised fire suppression systems.

Ask yourself or your crew

Do you have any fire suppression equipment that is not frequently used at your work site? Are you involved in using or testing this equipment?

Is all your emergency response equipment left in a ready state or tagged out accordingly?

Are line of fire exposures identified during routine operations tasks?

During a night shift, a portable fire water monitor separated under full system pressure, striking an operator in the chest and requiring first aid. The incident occurred because the monitor's spring-loaded locking pins were not fully engaged, which was difficult to detect in low light conditions.

Original material courtesy of Safer Together (Australia)

To access the PDF and PowerPoint versions, please visit https://www.safertogether.com.au/resources/sharing-library/operating-fire-suppression-systems-learning-event-bulletin