-

What happened?

A worker performing maintenance on a coiled tubing unit fell while exiting the control cabin

when the stairs became detached. The worker was seriously injured in the fall.

-

Why did it happen?

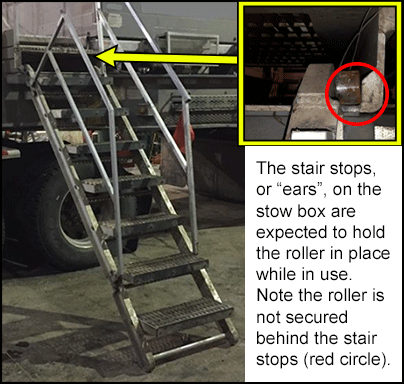

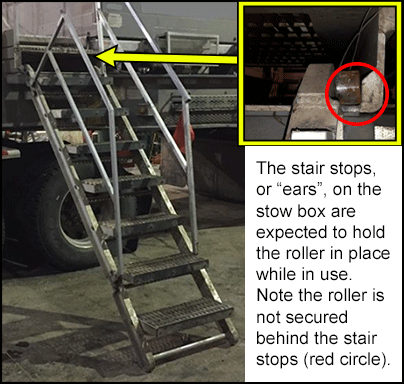

The stops holding the stairs in position did not hold. The stair stops “ears” were slightly bent,

allowing the stairs to escape the tracks.Contributing factors:

The original design of the stairs did not prevent this occurrence. It allowed movement within the stair roller and stop, which ultimately failed when worker exited the control cabin and stepped onto the stairs.

-

What did they learn?

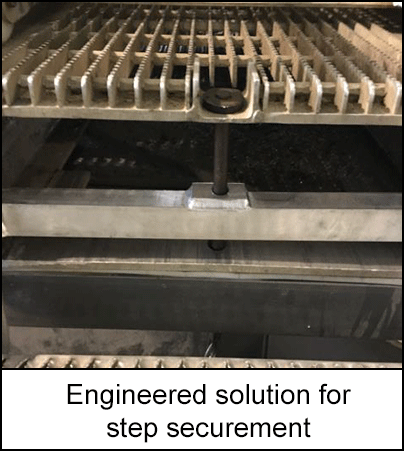

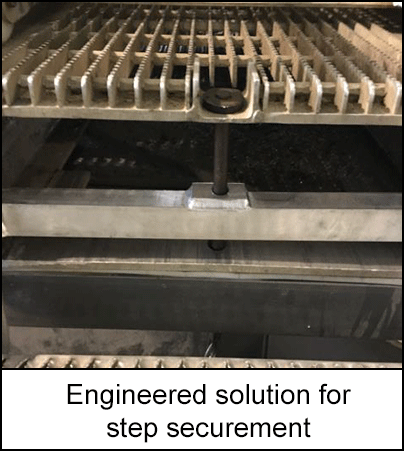

- The company inspected all stairs on other coil tubing units and developed a

permanent modification with the original equipment manufacturer. - Check stairs periodically to ensure they are secured and not damaged.

- The company inspected all stairs on other coil tubing units and developed a

-

Ask yourself or your crew

- How can something like this happen here (e.g. on our site)?

- What safety measures (i.e. procedures, controls/barriers) do we have in place to mitigate the risk?

- How do we know the risk controls/barriers are working?

- What improvements or changes should we make to the procedures, controls/barriers or the way we work?

Add to homescreen

If you want to add this app to home screen tap and then ‘Add to Home Screen’.

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A worker performing maintenance on a coiled tubing unit fell while exiting the control cabin

when the stairs became detached. The worker was seriously injured in the fall.

Why did it happen?

The stops holding the stairs in position did not hold. The stair stops “ears” were slightly bent,

allowing the stairs to escape the tracks.

Contributing factors:

The original design of the stairs did not prevent this occurrence. It allowed movement within the stair roller and stop, which ultimately failed when worker exited the control cabin and stepped onto the stairs.

What did they learn?

- The company inspected all stairs on other coil tubing units and developed a

permanent modification with the original equipment manufacturer. - Check stairs periodically to ensure they are secured and not damaged.

Ask yourself or your crew

- How can something like this happen here (e.g. on our site)?

- What safety measures (i.e. procedures, controls/barriers) do we have in place to mitigate the risk?

- How do we know the risk controls/barriers are working?

- What improvements or changes should we make to the procedures, controls/barriers or the way we work?

Published on 03/06/23

1669 Views

A worker performing maintenance on a coiled tubing unit fell while exiting the control cabin when the stairs became detached. The worker was seriously injured in the fall.

Original material courtesy of Energy Safety Canada