-

What happened?

A wellsite operator noticed a hydraulic power unit (HPU) making an abnormal noise. While troubleshooting the noise source, the operator’s personal gas monitor alarmed on high carbon monoxide.

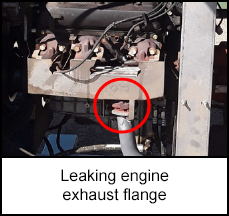

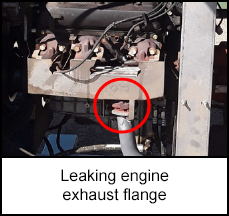

The operator continued troubleshooting and identified the source of the noise as a leaking engine exhaust flange.

On return to their vehicle, the operator felt increasingly unwell and activated their radio distress button to request emergency assistance.

The operator was later hospitalised exhibiting symptoms of carbon monoxide poisoning.

-

Why did it happen?

The engine exhaust flange was loose (chattering) at the ‘donut’ gasket (spring loaded flange) between the engine manifold and exhaust pipework.

Exhaust gas containing carbon monoxide was being released.

The operator perceived the risk of carbon monoxide exposure to be low and continued to work in the vicinity of the leak after acknowledging a personal gas monitoring alarm indicating high carbon monoxide.

-

What did they learn?

Communicate the risk of carbon monoxide poisoning when exposed to exhaust gases from combustion engines (including HPUs). This risk can be present outside of a confined space.

Reinforce the importance of following procedures when personal gas monitors alarm.

Determine and document flange management requirements for spring loaded joint types.

-

Ask yourself or your crew

Could you be exposed to carbon monoxide in the course of your work? How? How do you manage this risk?

Do you know the symptoms of carbon monoxide poisoning?

Do you know how to respond if your personal gas monitor alarms? Does your response change depending on the type of alarm (e.g. methane; carbon monoxide; hydrogen sulphide, low oxygen)?

Do you feel empowered to escalate concerns? Would you activate your distress button in an emergency?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A wellsite operator noticed a hydraulic power unit (HPU) making an abnormal noise. While troubleshooting the noise source, the operator’s personal gas monitor alarmed on high carbon monoxide.

The operator continued troubleshooting and identified the source of the noise as a leaking engine exhaust flange.

On return to their vehicle, the operator felt increasingly unwell and activated their radio distress button to request emergency assistance.

The operator was later hospitalised exhibiting symptoms of carbon monoxide poisoning.

Why did it happen?

The engine exhaust flange was loose (chattering) at the ‘donut’ gasket (spring loaded flange) between the engine manifold and exhaust pipework.

Exhaust gas containing carbon monoxide was being released.

The operator perceived the risk of carbon monoxide exposure to be low and continued to work in the vicinity of the leak after acknowledging a personal gas monitoring alarm indicating high carbon monoxide.

What did they learn?

Communicate the risk of carbon monoxide poisoning when exposed to exhaust gases from combustion engines (including HPUs). This risk can be present outside of a confined space.

Reinforce the importance of following procedures when personal gas monitors alarm.

Determine and document flange management requirements for spring loaded joint types.

Ask yourself or your crew

Could you be exposed to carbon monoxide in the course of your work? How? How do you manage this risk?

Do you know the symptoms of carbon monoxide poisoning?

Do you know how to respond if your personal gas monitor alarms? Does your response change depending on the type of alarm (e.g. methane; carbon monoxide; hydrogen sulphide, low oxygen)?

Do you feel empowered to escalate concerns? Would you activate your distress button in an emergency?

A wellsite operator was hospitalised with carbon monoxide poisoning after troubleshooting a hydraulic power unit following a high carbon monoxide alarm. The incident was caused by a leaking engine exhaust flange, which released exhaust gas containing carbon monoxide.

Original material courtesy of Safer Together (Australia)

To access the PDF and PowerPoint versions, please visit https://www.safertogether.com.au/resources/sharing-library/exposure-to-toxic-gas-chemical-learning-event-bulletin