-

What happened?

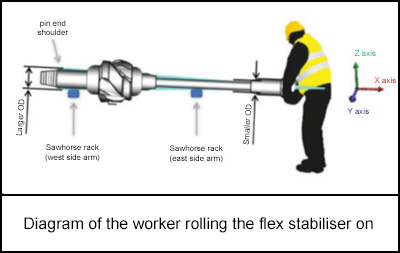

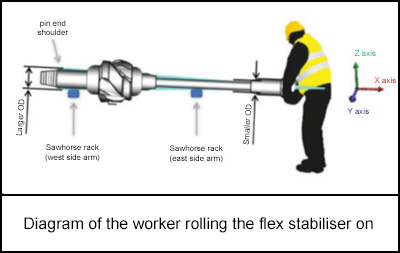

A warehouse and yard worker was rolling a flex stabiliser on a sawhorse rack.

One end of the tool dropped from the rack, causing the opposite end to fatally strike him.

-

Why did it happen?

The worker approached the flex stabiliser intending to move it along the sawhorse rack by rolling it.

As the tool started rolling along the sawhorse rack, the worker followed the movement parallel to the sawhorse rack arms.

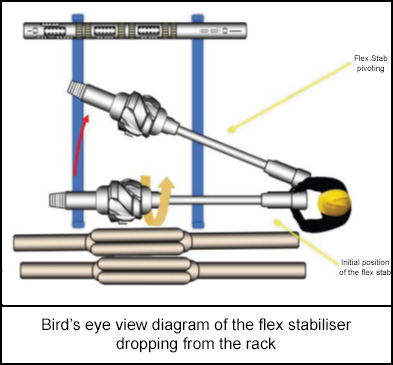

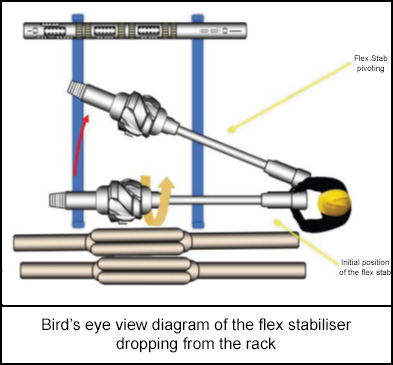

The flex stabiliser has different outer diameters (OD) on each end and completed about 3 to 4 rotations around the X axis, when the difference in OD caused the tool to pivot. The pin end of the flex stabiliser rotated approximately 7 inches (18 cm) inside the sawhorse rack arms.

As the flex stabiliser began to pivot, the pin end of the tool started to drop off the sawhorse rack arm. The worker reacted by grabbing the other end of the tool to stop the movement.

As the pin end dropped, it caused the other end of the tool to rapidly raise and lift the worker into the air, who then fell on two other tools located in front of the sawhorse rack.

Upon falling on the other tools, the flex stabiliser came to rest on top of the worker.

-

What did they learn?

Immediately stop storing tools with different outer diameters on sawhorse racks.

Confirm systems that store enough energy to potentially cause a fatality or serious injury are designed with adequate barriers to further reduce risk.

Safety training should include hazard identification and risk management.

-

Ask yourself or your crew

How do you store items with cylindrical shapes at your site, and how do you manage those with varying outer diameters at each end?

How do you ensure the safe storage of these items, such as using sawhorse racks?

What training have you received on the proper handling techniques for cylindrical items, and how it has influenced your approach? What should you do if you need additional training or a refresher?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A warehouse and yard worker was rolling a flex stabiliser on a sawhorse rack.

One end of the tool dropped from the rack, causing the opposite end to fatally strike him.

Why did it happen?

The worker approached the flex stabiliser intending to move it along the sawhorse rack by rolling it.

As the tool started rolling along the sawhorse rack, the worker followed the movement parallel to the sawhorse rack arms.

The flex stabiliser has different outer diameters (OD) on each end and completed about 3 to 4 rotations around the X axis, when the difference in OD caused the tool to pivot. The pin end of the flex stabiliser rotated approximately 7 inches (18 cm) inside the sawhorse rack arms.

As the flex stabiliser began to pivot, the pin end of the tool started to drop off the sawhorse rack arm. The worker reacted by grabbing the other end of the tool to stop the movement.

As the pin end dropped, it caused the other end of the tool to rapidly raise and lift the worker into the air, who then fell on two other tools located in front of the sawhorse rack.

Upon falling on the other tools, the flex stabiliser came to rest on top of the worker.

What did they learn?

Immediately stop storing tools with different outer diameters on sawhorse racks.

Confirm systems that store enough energy to potentially cause a fatality or serious injury are designed with adequate barriers to further reduce risk.

Safety training should include hazard identification and risk management.

Ask yourself or your crew

How do you store items with cylindrical shapes at your site, and how do you manage those with varying outer diameters at each end?

How do you ensure the safe storage of these items, such as using sawhorse racks?

What training have you received on the proper handling techniques for cylindrical items, and how it has influenced your approach? What should you do if you need additional training or a refresher?

A warehouse and yard worker was rolling a flex stabiliser on a sawhorse rack. One end of the tool dropped from the rack, causing the opposite end to fatally strike him.

Original material, and accompanying slideshow, courtesy of Safer Together (Australia)

To access the PDF and PowerPoint versions, please visit https://www.safertogether.com.au/resources/sharing-library/manual-handling-peson-in-line-of-fire-leb-toolbox