-

What happened?

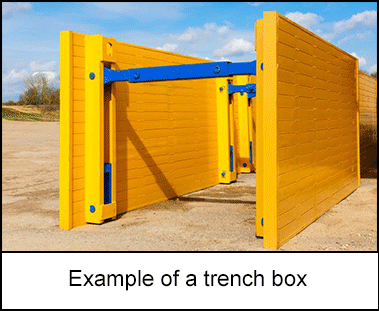

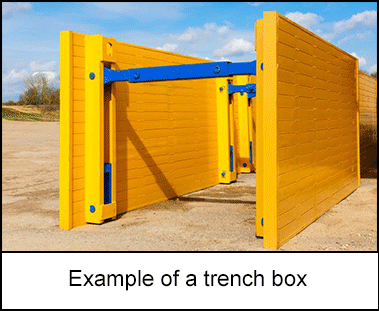

A work crew was on location to dismantle a high arch trench box and then transport the disassembled box from one project work site to another.

The disassembly process did not follow the manufacturer’s instructions for the safe removal of the strut support pins holding the box together. Consequently, when the last strut support pin was removed from the box, it collapsed, causing a support arch to strike and fatally injure a worker.

-

Why did it happen?

The disassembly process did not follow the manufacturer’s instructions for the safe removal of the strut support pins holding the box together.

-

What did they learn?

Trench boxes are a protective system used to protect workers from the pressure and weight of soil in the event of a cave-in. It is critical to ensure that processes are followed to prevent unexpected movement of trench box panels which can cause serious harm or death. Not all trench boxes are the same – identify and know the specifications for the equipment that is being used.

These were the recommendations following the incident:

- Ensure supervisors, workers and inspectors are trained in the use and inspection of the specific

trench box being used. All trench box systems come with assembly, use and disassembly instructions.

Always follow the manufacturer’s instructions. - The installation, removal, assembly and disassembly of any trench box must only be done by a

competent and qualified person(s) including workers, supervisors and inspectors. - Never stand in the line of fire. Ensure everyone on site is positioned to avoid moving objects,

vehicles, pressure releases and dropped objects.

- Ensure supervisors, workers and inspectors are trained in the use and inspection of the specific

-

Ask yourself or your crew

- How can something like this happen here (e.g. on our site)?

- What safety measures (i.e. procedures, controls/barriers) do we have in place to mitigate the risk?

- How do we know the risk controls/barriers are working?

- What improvements or changes should we make to the procedures, controls/barriers or the way we work?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A work crew was on location to dismantle a high arch trench box and then transport the disassembled box from one project work site to another.

The disassembly process did not follow the manufacturer’s instructions for the safe removal of the strut support pins holding the box together. Consequently, when the last strut support pin was removed from the box, it collapsed, causing a support arch to strike and fatally injure a worker.

Why did it happen?

The disassembly process did not follow the manufacturer’s instructions for the safe removal of the strut support pins holding the box together.

What did they learn?

Trench boxes are a protective system used to protect workers from the pressure and weight of soil in the event of a cave-in. It is critical to ensure that processes are followed to prevent unexpected movement of trench box panels which can cause serious harm or death. Not all trench boxes are the same – identify and know the specifications for the equipment that is being used.

These were the recommendations following the incident:

- Ensure supervisors, workers and inspectors are trained in the use and inspection of the specific

trench box being used. All trench box systems come with assembly, use and disassembly instructions.

Always follow the manufacturer’s instructions. - The installation, removal, assembly and disassembly of any trench box must only be done by a

competent and qualified person(s) including workers, supervisors and inspectors. - Never stand in the line of fire. Ensure everyone on site is positioned to avoid moving objects,

vehicles, pressure releases and dropped objects.

Ask yourself or your crew

- How can something like this happen here (e.g. on our site)?

- What safety measures (i.e. procedures, controls/barriers) do we have in place to mitigate the risk?

- How do we know the risk controls/barriers are working?

- What improvements or changes should we make to the procedures, controls/barriers or the way we work?

A work crew was on location to dismantle a high arch trench box and then transport the disassembled box from one project work site to another. When the last strut support pin was removed from the box, it collapsed, causing a support arch to strike and fatally injure a worker.

Original material courtesy of Energy Safety Canada

Other resources:

The Trenching and Excavation Fact Sheet by The Canadian Centre for Occupational Health and Safety.

Line of fire - watch video

Safe mechanical lifting - watch video

Life saving rules