-

What happened?

A drill pad build crew requested a water cart to come to site and refill a water pod on the back of the crew’s truck tray. When the water cart arrived at site it parked next to the tray truck.

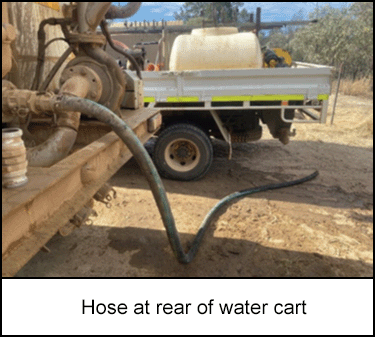

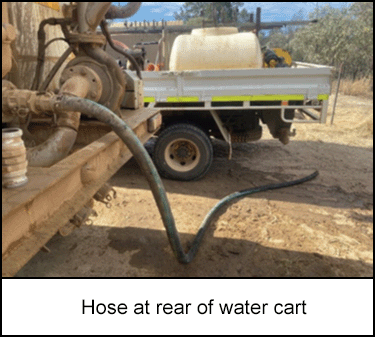

The operator of the water cart connected a 50mm (2 inches) hose to the rear of the water cart. The hose was given to one of the pad build crew to insert into the water pod – who then got up onto the back of the crew’s truck tray, between the tailgate and the pod, to hold the hose while it filled the water pod.

The water cart operator climbed back into their truck’s cab to operate the tanker power take-off (PTO). Noting that the pad build crew member was holding the hose in place, the water cart operator started up the PTO.

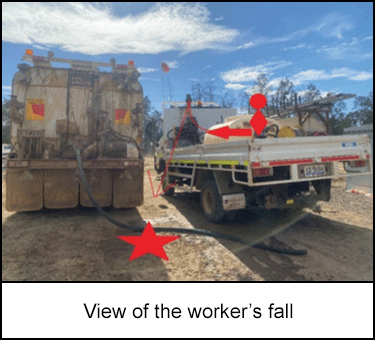

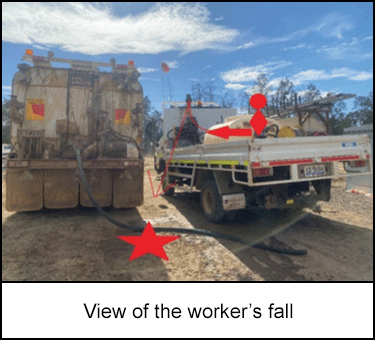

The water cart operator noticed that the hose had kicked out and turned off the PTO/water flow. They then went to the back of the water cart to investigate, and noticed the pad build crew worker had fallen approximately 1.2m (3.9 feet) to the ground. The pad build crew worker sustained fractures to both wrists.

-

Why did it happen?

The operating pressure had been set at 60-70 psi (4.1-4.8 bar).

The 50mm (2 inches) hose did not have a fitting at its outlet.

As such, the water came out at the set pressure in one continuous flow (i.e. didn’t start at a lower pressure and build up to the set pressure).

The hose kicked the pad build crew member from the tray truck.

-

What did they learn?

Use “transition to work” and “step 7 process”, or more relevant local standards, to review tasks. Ensure the hazards associated with the work method are identified and controls implemented prior to starting work. A job hazard analysis (JHA) had been developed for the work but did not include filling of the water pod.

A full review of water pod placement has been conducted across all sites. Water pods were previously used on trailers, which are at a lower height than crew trucks, but these had been removed from all sites and replaced by water pods on the back of crew trucks. There is no record of a management of change process / risk assessment.

The only way to fill the pods is through an opening at the top of the water pod. Full review of water pod filling process has been conducted across all sites ensuring correct equipment is used to transfer water.

Do not access or work on truck trays without adequate fall prevention controls.

-

Ask yourself or your crew

Does your work involve filling water pods? Do you have the correct equipment for this task?

How do you manage water pressure while filling water pods?

Do you need to work at height to fill water pods? How do you manage this risk?

Do you need to access truck trays to conduct your work?

What fall prevention controls do you have in place when accessing truck trays?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A drill pad build crew requested a water cart to come to site and refill a water pod on the back of the crew’s truck tray. When the water cart arrived at site it parked next to the tray truck.

The operator of the water cart connected a 50mm (2 inches) hose to the rear of the water cart. The hose was given to one of the pad build crew to insert into the water pod – who then got up onto the back of the crew’s truck tray, between the tailgate and the pod, to hold the hose while it filled the water pod.

The water cart operator climbed back into their truck’s cab to operate the tanker power take-off (PTO). Noting that the pad build crew member was holding the hose in place, the water cart operator started up the PTO.

The water cart operator noticed that the hose had kicked out and turned off the PTO/water flow. They then went to the back of the water cart to investigate, and noticed the pad build crew worker had fallen approximately 1.2m (3.9 feet) to the ground. The pad build crew worker sustained fractures to both wrists.

Why did it happen?

The operating pressure had been set at 60-70 psi (4.1-4.8 bar).

The 50mm (2 inches) hose did not have a fitting at its outlet.

As such, the water came out at the set pressure in one continuous flow (i.e. didn’t start at a lower pressure and build up to the set pressure).

The hose kicked the pad build crew member from the tray truck.

What did they learn?

Use “transition to work” and “step 7 process”, or more relevant local standards, to review tasks. Ensure the hazards associated with the work method are identified and controls implemented prior to starting work. A job hazard analysis (JHA) had been developed for the work but did not include filling of the water pod.

A full review of water pod placement has been conducted across all sites. Water pods were previously used on trailers, which are at a lower height than crew trucks, but these had been removed from all sites and replaced by water pods on the back of crew trucks. There is no record of a management of change process / risk assessment.

The only way to fill the pods is through an opening at the top of the water pod. Full review of water pod filling process has been conducted across all sites ensuring correct equipment is used to transfer water.

Do not access or work on truck trays without adequate fall prevention controls.

Ask yourself or your crew

Does your work involve filling water pods? Do you have the correct equipment for this task?

How do you manage water pressure while filling water pods?

Do you need to work at height to fill water pods? How do you manage this risk?

Do you need to access truck trays to conduct your work?

What fall prevention controls do you have in place when accessing truck trays?

A pad build crew member fell from a truck and fractured both wrists after a high-pressure water hose, lacking an outlet fitting, kicked out and knocked them off the truck during a water refill operation.

Original material courtesy of Safer Together (Australia)

To access the PDF and PowerPoint versions, please visit https://www.safertogether.com.au/resources/sharing-library/loading-unloading-person-fall-from-height-leb-toolbox