-

What happened?

Two workers were removing an alignment bolt from an out-of-service pumpjack horse head at a storage yard.

The horse head was connected to the walking beam and situated in an upright position, therefore containing stored energy.

“Worker A” was positioned under the walking beam. When “Worker B” began removing the alignment bolt, the walking beam collapsed, crushing and fatally injuring “Worker A”.

-

Why did it happen?

Failure to identify and control stored energy hazard: The stored energy hazard of the elevated horse head and walking beam was not identified or controlled.

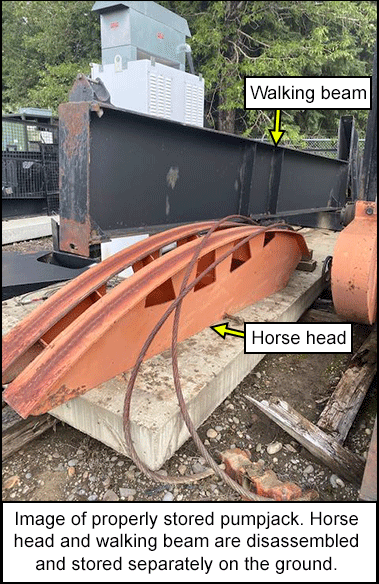

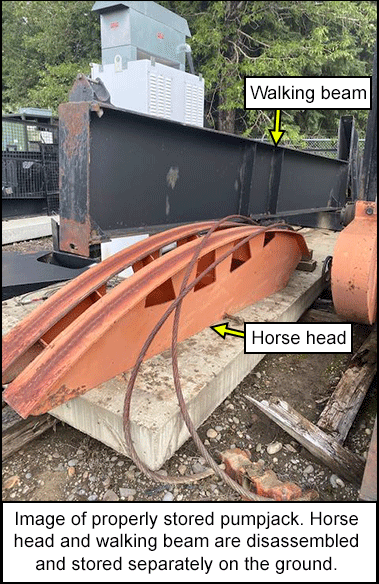

Improper storage and securing of out-of-service pumpjack: An out-of-service pumpjack was stored in an upright or elevated position and the horse head had remained attached to the walking beam. The safety bar that secures the horse head to the walking beam was not in place.

Unsafe work positioning: A worker was positioned in the line of fire when the alignment bolt was loosened and the walking beam fell.

-

What did they learn?

- The stored energy hazard of the elevated horse head and walking beam was not identified or controlled.

- An out-of-service pumpjack was stored in an upright or elevated position and the horse head had remained attached to the walking beam. The safety bar that secures the horse head to the walking beam was not in place.

- A worker was positioned in the line of fire when the alignment bolt was loosened and the walking beam fell.

- Inspect storage yards for stored energy hazards associated with pumpjacks, components and other equipment and ensure controls are in place.

- Disassemble and store out-of-service pumpjack components separately and on the ground.

- Perform a risk assessment of other stored materials or equipment that could fall or present a potential stored energy hazard and ensure the appropriate controls are in place.

- Discuss this incident at safety meetings to highlight the importance of completing a comprehensive hazard assessment before starting work.

-

Ask yourself or your crew

- How can something like this happen here (e.g. on our site)?

- What safety measures (i.e. procedures, controls/barriers) do we have in place to mitigate the risk?

- How do we know the risk controls/barriers are working?

- What improvements or changes should we make to the procedures, controls/barriers or the way we work?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

Two workers were removing an alignment bolt from an out-of-service pumpjack horse head at a storage yard.

The horse head was connected to the walking beam and situated in an upright position, therefore containing stored energy.

“Worker A” was positioned under the walking beam. When “Worker B” began removing the alignment bolt, the walking beam collapsed, crushing and fatally injuring “Worker A”.

Why did it happen?

Failure to identify and control stored energy hazard: The stored energy hazard of the elevated horse head and walking beam was not identified or controlled.

Improper storage and securing of out-of-service pumpjack: An out-of-service pumpjack was stored in an upright or elevated position and the horse head had remained attached to the walking beam. The safety bar that secures the horse head to the walking beam was not in place.

Unsafe work positioning: A worker was positioned in the line of fire when the alignment bolt was loosened and the walking beam fell.

What did they learn?

- The stored energy hazard of the elevated horse head and walking beam was not identified or controlled.

- An out-of-service pumpjack was stored in an upright or elevated position and the horse head had remained attached to the walking beam. The safety bar that secures the horse head to the walking beam was not in place.

- A worker was positioned in the line of fire when the alignment bolt was loosened and the walking beam fell.

- Inspect storage yards for stored energy hazards associated with pumpjacks, components and other equipment and ensure controls are in place.

- Disassemble and store out-of-service pumpjack components separately and on the ground.

- Perform a risk assessment of other stored materials or equipment that could fall or present a potential stored energy hazard and ensure the appropriate controls are in place.

- Discuss this incident at safety meetings to highlight the importance of completing a comprehensive hazard assessment before starting work.

Ask yourself or your crew

- How can something like this happen here (e.g. on our site)?

- What safety measures (i.e. procedures, controls/barriers) do we have in place to mitigate the risk?

- How do we know the risk controls/barriers are working?

- What improvements or changes should we make to the procedures, controls/barriers or the way we work?

Two workers were removing an alignment bolt from an out-of-service pumpjack horse head at a storage yard. Worker A was positioned under the walking beam. When worker B began removing the alignment bolt, the walking beam collapsed, fatally injuring worker A.