-

What happened?

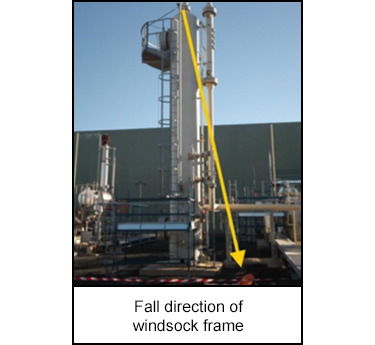

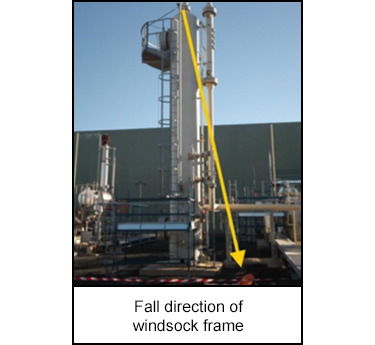

A processing plant operator undertaking routine facility checks discovered that the facility’s windsock frame had fallen to the ground during a storm on the previous night.

The windsock pole had been bent over and was resting on a vent support.

The windsock frame weighing about 1.5 kg (3.3 lbs) had dislodged from the end of the pole and fallen about 9.5 m (31.2 ft) to the ground.

No personnel were on site at the time of the event.

-

Why did it happen?

The windsock frame structure was temporary and not designed for the wind loading experienced during the storm.

It was difficult to access for inspection. Cracks in the post were undetected.

A preventive inspection/maintenance program was not in place for the structure.

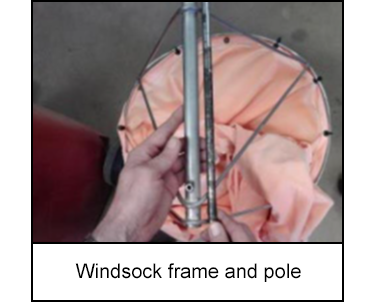

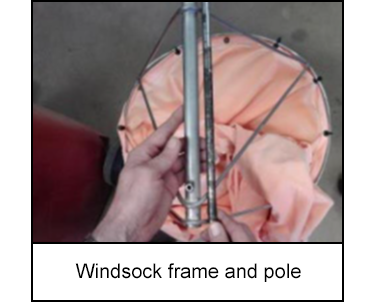

The windsock frame (with retainer screw) had been updated with a new design. However, the shaft retained the old design.

The design change had not been subject to Management of Change processes.

-

What did they learn?

Review all windsock structures to ensure they are adequately designed and subject to preventive inspection/maintenance programs.

Identify temporary structures. Confirm that they have been subject to Management of Change processes and included in ongoing preventative inspection/maintenance programs and/or decide to replace with a permanent structure.

-

Ask yourself or your crew

Are the windsock structures on your facility adequately designed? Are they routinely inspected and maintained?

Are there any temporary structures at your site? Were they subjected to Management of Change processes? Are they inspected / maintained? Should they be replaced with permanent structures?

Have you identified the potential for dropped objects caused by inadequate securing, corrosion, vibration or environmental factors (e.g. wind)? Have you reported these potential dropped objects?

Do you check for potential dropped objects before and after storms?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A processing plant operator undertaking routine facility checks discovered that the facility’s windsock frame had fallen to the ground during a storm on the previous night.

The windsock pole had been bent over and was resting on a vent support.

The windsock frame weighing about 1.5 kg (3.3 lbs) had dislodged from the end of the pole and fallen about 9.5 m (31.2 ft) to the ground.

No personnel were on site at the time of the event.

Why did it happen?

The windsock frame structure was temporary and not designed for the wind loading experienced during the storm.

It was difficult to access for inspection. Cracks in the post were undetected.

A preventive inspection/maintenance program was not in place for the structure.

The windsock frame (with retainer screw) had been updated with a new design. However, the shaft retained the old design.

The design change had not been subject to Management of Change processes.

What did they learn?

Review all windsock structures to ensure they are adequately designed and subject to preventive inspection/maintenance programs.

Identify temporary structures. Confirm that they have been subject to Management of Change processes and included in ongoing preventative inspection/maintenance programs and/or decide to replace with a permanent structure.

Ask yourself or your crew

Are the windsock structures on your facility adequately designed? Are they routinely inspected and maintained?

Are there any temporary structures at your site? Were they subjected to Management of Change processes? Are they inspected / maintained? Should they be replaced with permanent structures?

Have you identified the potential for dropped objects caused by inadequate securing, corrosion, vibration or environmental factors (e.g. wind)? Have you reported these potential dropped objects?

Do you check for potential dropped objects before and after storms?

During a routine check, a processing plant operator discovered that a storm had caused the facility’s windsock frame to fall from a height of 9.5 metres (31.2 feet) after the pole bent and dislodged the frame. Fortunately, no personnel were present at the time of the incident.

Original material courtesy of Safer Together (Australia)

To access the PDF and PowerPoint versions, please visit https://www.safertogether.com.au/resources/sharing-library/working-on-near-fixed-equipment-line-of-fire-learning-event-bulletin