-

What happened?

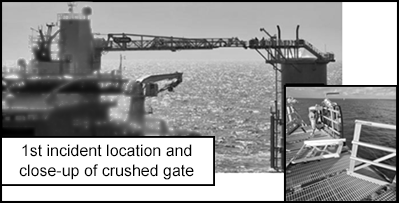

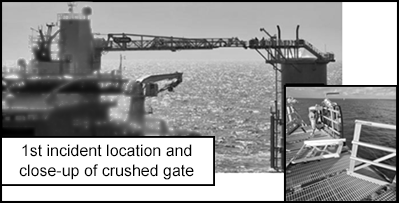

1st incident: Slip-off during the connection process – material damage

A vessel experienced rapid movement caused by a 90-degree incoming residual swell, leading to the W2W slipping off the landing beam.

The walk to work (W2W) gangway continued to extend through the transition piece (TP) gates onto the TP platform, crushing the gate and damaging equipment.

When retracting, the gangway moved sideways exposing three passengers at the TP deck that were waiting to transfer to the service operation vessel (SOV).

No injuries occurred but the gangway narrowly missed hitting individuals.

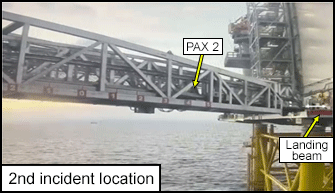

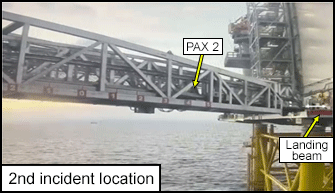

2nd incident: Gangway retraction during personnel transfer – no injuries

The gangway detected a lost connection to the offshore support platform and retracted.

An individual located on the gangway was in the brace position but lost his balance and stumbled to the floor.

Once the gangway stabilised, the individual managed to regain footing and safely return to the vessel.

It's worth noting that the sea-state and weather conditions remained calm throughout the incident.

There were no material damages or injuries, although a fall into the sea with serious consequences was a potential risk.

-

Why did it happen?

Causes identified following the first incident.

The software settings were found to be incorrect and the telescope speed too slow when connected.

There was a lack of manual interaction to minimise gangway movement.

The automatic slip off system (safety system) did not work.

The load cells showed incorrect readings.

The load cell tensions rod was not secured and working loose.

Additional causes identified following the second incident.

There was a false slip-off detection due to incorrect load cells and rod coming loose.

The control system was designed to immediately disconnect. The gangway operator manually stopped further retraction.

There was insufficient quality control during fabrication.

-

What did they learn?

Learnings from both incidents

Regular inspections should include assessment of load cells to ensure their proper functioning.

The slip-off detection function is a barrier itself. Ensure that the hardware and arrangement providing input to the slip-off detection function are regularly inspected and maintained to prevent inadvertent activation of the barrier.

The W2W gangway operator should be able to read the bumper load directly from the main screen.

Training and instruction relating to the gangway should focus on the slip off detection function, associated arrangement and actions/awareness required to the level relevant to the full and safe operation of the function.

Users should receive training on maintaining a safe distance.

Suppliers of equipment like the W2W gangway should issue notices to customers regarding load cell installation and software updates.

Quality control during fabrication should be enforced.

During the second incident, several intact barriers were noted:

The individual followed their training.

The gangway operator promptly halted further retraction manually.

Prechecks and connection of the W2W gangway were completed in accordance with procedures and checklists.

-

Ask yourself or your crew

How can something similar happen here? What specific factors or conditions might lead to a similar incident occurring in our work environment?

What procedures and checklists do you follow when conducting prechecks and connecting the walk-to-work gangway?

Can you describe your understanding of the slip-off detection function and how it operates during gangway operation? What would the consequences be if this function were to fail?

How do we anticipate the weather/sea conditions? Does the software need to be updated accordingly to factor in these conditions?

What measures do we have in place to prevent similar incidents on our site? What else can we do to enhance safety in your workplace?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

1st incident: Slip-off during the connection process – material damage

A vessel experienced rapid movement caused by a 90-degree incoming residual swell, leading to the W2W slipping off the landing beam.

The walk to work (W2W) gangway continued to extend through the transition piece (TP) gates onto the TP platform, crushing the gate and damaging equipment.

When retracting, the gangway moved sideways exposing three passengers at the TP deck that were waiting to transfer to the service operation vessel (SOV).

No injuries occurred but the gangway narrowly missed hitting individuals.

2nd incident: Gangway retraction during personnel transfer – no injuries

The gangway detected a lost connection to the offshore support platform and retracted.

An individual located on the gangway was in the brace position but lost his balance and stumbled to the floor.

Once the gangway stabilised, the individual managed to regain footing and safely return to the vessel.

It's worth noting that the sea-state and weather conditions remained calm throughout the incident.

There were no material damages or injuries, although a fall into the sea with serious consequences was a potential risk.

Why did it happen?

Causes identified following the first incident.

The software settings were found to be incorrect and the telescope speed too slow when connected.

There was a lack of manual interaction to minimise gangway movement.

The automatic slip off system (safety system) did not work.

The load cells showed incorrect readings.

The load cell tensions rod was not secured and working loose.

Additional causes identified following the second incident.

There was a false slip-off detection due to incorrect load cells and rod coming loose.

The control system was designed to immediately disconnect. The gangway operator manually stopped further retraction.

There was insufficient quality control during fabrication.

What did they learn?

Learnings from both incidents

Regular inspections should include assessment of load cells to ensure their proper functioning.

The slip-off detection function is a barrier itself. Ensure that the hardware and arrangement providing input to the slip-off detection function are regularly inspected and maintained to prevent inadvertent activation of the barrier.

The W2W gangway operator should be able to read the bumper load directly from the main screen.

Training and instruction relating to the gangway should focus on the slip off detection function, associated arrangement and actions/awareness required to the level relevant to the full and safe operation of the function.

Users should receive training on maintaining a safe distance.

Suppliers of equipment like the W2W gangway should issue notices to customers regarding load cell installation and software updates.

Quality control during fabrication should be enforced.

During the second incident, several intact barriers were noted:

The individual followed their training.

The gangway operator promptly halted further retraction manually.

Prechecks and connection of the W2W gangway were completed in accordance with procedures and checklists.

Ask yourself or your crew

How can something similar happen here? What specific factors or conditions might lead to a similar incident occurring in our work environment?

What procedures and checklists do you follow when conducting prechecks and connecting the walk-to-work gangway?

Can you describe your understanding of the slip-off detection function and how it operates during gangway operation? What would the consequences be if this function were to fail?

How do we anticipate the weather/sea conditions? Does the software need to be updated accordingly to factor in these conditions?

What measures do we have in place to prevent similar incidents on our site? What else can we do to enhance safety in your workplace?

In two separate incidents, both involving gangway operations during personnel transfers, notable safety concerns arose. Despite no injuries occurring in either incident, the potential risks, especially in the context of calm sea-state and weather conditions, highlight the importance of stringent safety protocols during gangway operations to prevent accidents and ensure personnel safety.