-

What happened?

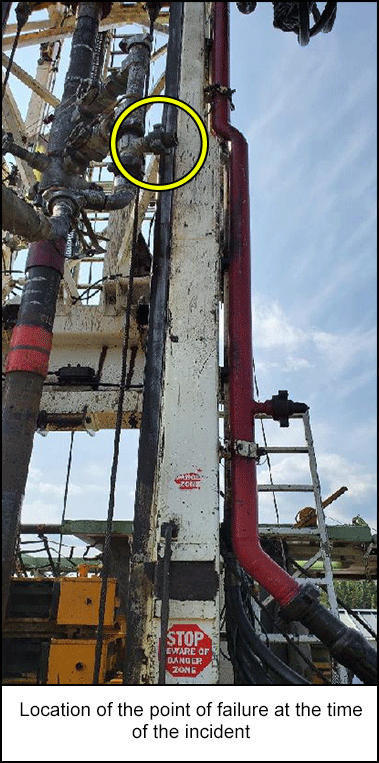

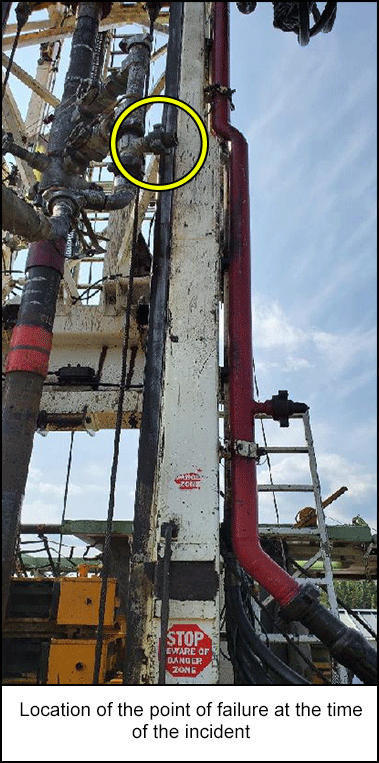

While reciprocating casing during a cement job, a valve weighing greater than 15 kg broke off at the threaded nipple union and fell approximately 5 to 6 m, striking a worker in the leg and causing serious injury.

Iron securement slings were installed on the treating iron on the rig floor. However, due to the location of the failure on the valve, it slipped through and fell.

-

Why did it happen?

- A non-integral valve—a valve that is an assembly of numerous parts rather than one piece—was used on the rig floor as a pump-out line. Although this was a low-pressure application and did not exceed the pressure rating on the valve, a non-integral component is more susceptible to mechanical failure than an integral component.

- Iron securement system and installation did not adequately prevent this valve from falling due to failure at the threaded connection.

-

What did they learn?

- Eliminate the use of non-integral components on the rig floor treating iron.

- Install secondary securement on components that have the potential to slip through the primary securement system.

- Develop and implement training on iron securement procedures with a focus on dropped object prevention.

- Increase awareness of potential dropped object hazards through hazard ID program.

-

Ask yourself or your crew

- How can something like this happen here (e.g. on our site)?

- What safety measures (i.e. procedures, controls/barriers) do we have in place to mitigate the risk?

- How do we know the risk controls/barriers are working?

- What improvements or changes should we make to the procedures, controls/barriers or the way we work?

Add to homescreen

If you want to add this app to home screen tap and then ‘Add to Home Screen’.

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

While reciprocating casing during a cement job, a valve weighing greater than 15 kg broke off at the threaded nipple union and fell approximately 5 to 6 m, striking a worker in the leg and causing serious injury.

Iron securement slings were installed on the treating iron on the rig floor. However, due to the location of the failure on the valve, it slipped through and fell.

Why did it happen?

- A non-integral valve—a valve that is an assembly of numerous parts rather than one piece—was used on the rig floor as a pump-out line. Although this was a low-pressure application and did not exceed the pressure rating on the valve, a non-integral component is more susceptible to mechanical failure than an integral component.

- Iron securement system and installation did not adequately prevent this valve from falling due to failure at the threaded connection.

What did they learn?

- Eliminate the use of non-integral components on the rig floor treating iron.

- Install secondary securement on components that have the potential to slip through the primary securement system.

- Develop and implement training on iron securement procedures with a focus on dropped object prevention.

- Increase awareness of potential dropped object hazards through hazard ID program.

Ask yourself or your crew

- How can something like this happen here (e.g. on our site)?

- What safety measures (i.e. procedures, controls/barriers) do we have in place to mitigate the risk?

- How do we know the risk controls/barriers are working?

- What improvements or changes should we make to the procedures, controls/barriers or the way we work?

Published on 14/04/23

977 Views

While reciprocating casing during a cement job, a valve weighing greater than 15 kg broke off at the threaded nipple union and fell approximately 5 to 6 m, striking a worker in the leg and causing serious injury.

Original material courtesy of Energy Safety Canada

Other resources:

Dropped Objects Best Practice

Dropped Objects Microlearning Video

Energy Safety Canada has partnered with DROPS (DropsOnline.org) in the establishment of a Canadian chapter. To become a member, review the Terms of Reference on the Canadian Chapter DROPS website and send an email to express your interest.

Are You in the “Line of Fire?” Program