-

What happened?

During grouting operations on an offshore platform, a valve on the overflow system was ejected unexpectedly.

Grout sprayed across the platform’s outer ring, damaging equipment but not injuring personnel.

The incident occurred despite personal protective equipment (PPE) use, lockout/tagout (LOTO) procedures, and phase separation between bolting and grouting.

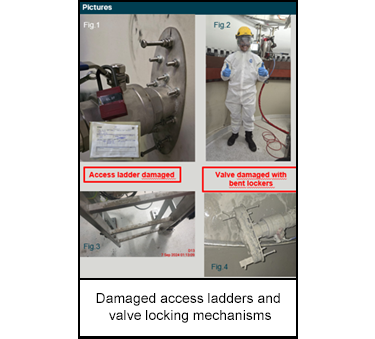

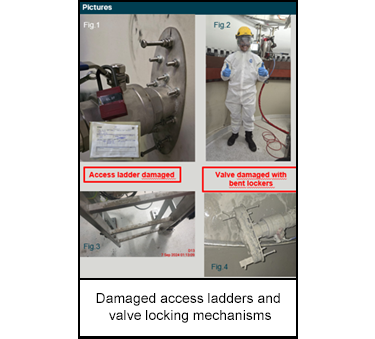

The access ladder and valve locking mechanisms were visibly damaged.

-

Why did it happen?

A valve failed under pressure during grout overflow, despite being part of a controlled process.

The physical forces behind the grout blow were not fully accounted for in the system design.

Previous similar incidents suggest a recurring issue with valve integrity under pressure.

The mitigation measures in place did not prevent equipment damage.

A detailed root cause analysis is underway to understand the failure mechanism.

-

What did they learn?

Overflow systems must be reassessed for pressure resilience and valve reliability.

Damage to equipment highlights the need for improved physical safeguards.

Incident documentation is essential for refining investigation and mitigation strategies.

PPE used and procedural controls were effective in preventing injury but not asset damage.

Future mitigation plans must include engineering and procedural updates.

-

Ask yourself or your crew

Are our overflow systems designed to withstand unexpected pressure surges?

How do we verify valve integrity before and during grouting operations?

What improvements can be made to protect equipment from grout blow incidents?

Are our mitigation strategies based on lessons from previous similar events?

How can we better separate high-risk phases of operations to reduce exposure?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

During grouting operations on an offshore platform, a valve on the overflow system was ejected unexpectedly.

Grout sprayed across the platform’s outer ring, damaging equipment but not injuring personnel.

The incident occurred despite personal protective equipment (PPE) use, lockout/tagout (LOTO) procedures, and phase separation between bolting and grouting.

The access ladder and valve locking mechanisms were visibly damaged.

Why did it happen?

A valve failed under pressure during grout overflow, despite being part of a controlled process.

The physical forces behind the grout blow were not fully accounted for in the system design.

Previous similar incidents suggest a recurring issue with valve integrity under pressure.

The mitigation measures in place did not prevent equipment damage.

A detailed root cause analysis is underway to understand the failure mechanism.

What did they learn?

Overflow systems must be reassessed for pressure resilience and valve reliability.

Damage to equipment highlights the need for improved physical safeguards.

Incident documentation is essential for refining investigation and mitigation strategies.

PPE used and procedural controls were effective in preventing injury but not asset damage.

Future mitigation plans must include engineering and procedural updates.

Ask yourself or your crew

Are our overflow systems designed to withstand unexpected pressure surges?

How do we verify valve integrity before and during grouting operations?

What improvements can be made to protect equipment from grout blow incidents?

Are our mitigation strategies based on lessons from previous similar events?

How can we better separate high-risk phases of operations to reduce exposure?

A valve was unexpectedly ejected during offshore grouting, spraying grout and damaging equipment. PPE and LOTO were in place; no injuries occurred.