-

What happened?

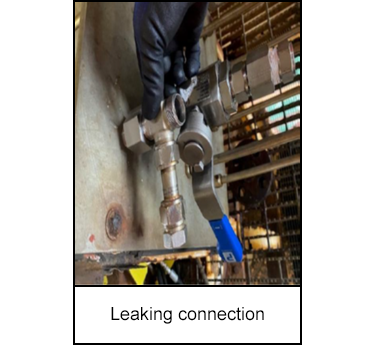

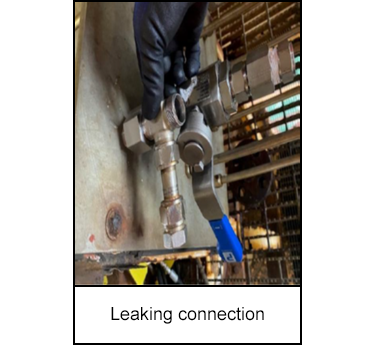

During the start of a flushing operation, which involved pressurising the system to clean the pipework, the vendor crew observed a leak at the connection point between a hose and a valve.

This connection serves as the initial point in which pressure is introduced. The pressure was at around 10 bar when the leak was discovered.

The operation was immediately stopped, and the system depressurised to ambient pressure to allow for an investigation to be completed on the platform by the Offshore Installation Manager (OIM) and Instrument Technician.

The fitting was found to still be leaking at ambient pressure. The OIM and Instrument Technician attended the worksite to carry out a check of the leaking fittings and surrounding fittings.

The Instrument technician identified that a Parker style fitting had been tied into an adjacent incompatible ¾ inch (1.9cm) national pipe thread (NPT) fitting with force, and the thread was damaged.

The full working pressure for the task was 50 bar. There was potential for this connection to fail if this pressure was reached resulting in potential for projectiles and / or pressure injury.

-

Why did it happen?

Incompatible fittings were used despite compatible fittings being available.

Suitability of fittings was not challenged and stop work authority not enforced.

Technician had completed small bore tubing training, but not the required technical test or job-based assessment to demonstrate competency.

Competency records were not accessed or reviewed to ensure competency of technician.

Shortage of core crew Instrument Technicians available in the field.

-

What did they learn?

Technical test and job-based assessment should be completed prior to working with small bore tubing.

Safety briefing to be completed across the field to all personnel on the topic of ‘stop work’ authority.

Ensure the activity is monitored and all personnel are reminded to use the correct tools and equipment prior to start of work.

Issue regarding shortage of Instrument Technicians in the field to be flagged and addressed by asset/project management.

Ensure personnel competencies are reviewed prior to mobilisation and a robust process for reviewing competency is in place.

-

Ask yourself or your crew

How do we verify that fittings and tools are compatible before use?

What improvements or changes should we make to the procedures, controls/barriers, or the way we work?

How do we verify competency of personnel?

How can we better support the use of stop work authority in the field?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

During the start of a flushing operation, which involved pressurising the system to clean the pipework, the vendor crew observed a leak at the connection point between a hose and a valve.

This connection serves as the initial point in which pressure is introduced. The pressure was at around 10 bar when the leak was discovered.

The operation was immediately stopped, and the system depressurised to ambient pressure to allow for an investigation to be completed on the platform by the Offshore Installation Manager (OIM) and Instrument Technician.

The fitting was found to still be leaking at ambient pressure. The OIM and Instrument Technician attended the worksite to carry out a check of the leaking fittings and surrounding fittings.

The Instrument technician identified that a Parker style fitting had been tied into an adjacent incompatible ¾ inch (1.9cm) national pipe thread (NPT) fitting with force, and the thread was damaged.

The full working pressure for the task was 50 bar. There was potential for this connection to fail if this pressure was reached resulting in potential for projectiles and / or pressure injury.

Why did it happen?

Incompatible fittings were used despite compatible fittings being available.

Suitability of fittings was not challenged and stop work authority not enforced.

Technician had completed small bore tubing training, but not the required technical test or job-based assessment to demonstrate competency.

Competency records were not accessed or reviewed to ensure competency of technician.

Shortage of core crew Instrument Technicians available in the field.

What did they learn?

Technical test and job-based assessment should be completed prior to working with small bore tubing.

Safety briefing to be completed across the field to all personnel on the topic of ‘stop work’ authority.

Ensure the activity is monitored and all personnel are reminded to use the correct tools and equipment prior to start of work.

Issue regarding shortage of Instrument Technicians in the field to be flagged and addressed by asset/project management.

Ensure personnel competencies are reviewed prior to mobilisation and a robust process for reviewing competency is in place.

Ask yourself or your crew

How do we verify that fittings and tools are compatible before use?

What improvements or changes should we make to the procedures, controls/barriers, or the way we work?

How do we verify competency of personnel?

How can we better support the use of stop work authority in the field?

A leaking connection during pressure testing revealed the use of incompatible fittings. The system was depressurised and the issue traced to a damaged thread.