-

What happened?

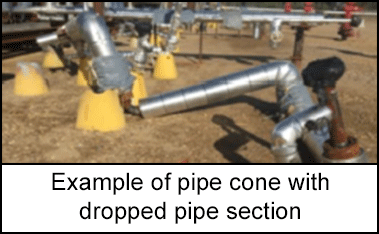

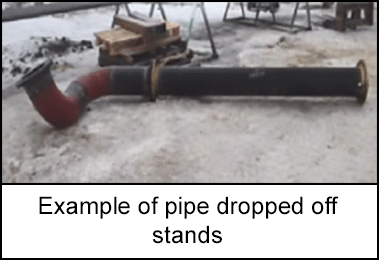

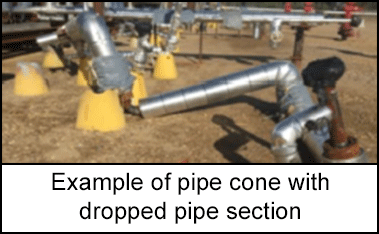

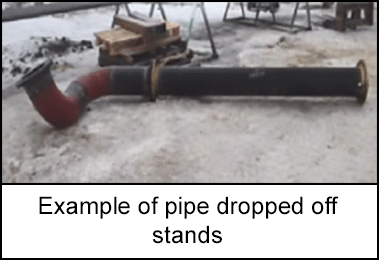

Multiple incidents of pipe drops occurred in the recent year.

These incidents resulted in injuries to workers that had the potential to be more serious. It also resulted in damage to pipe sections.

-

Why did it happen?

The incidents all have a common cause, safe staging and securement of pipe at the worksite did not take place.

-

What did they learn?

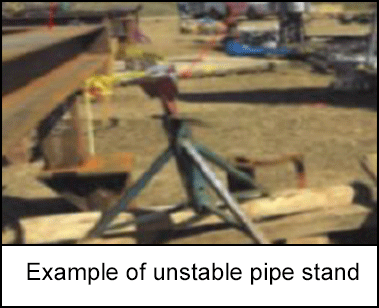

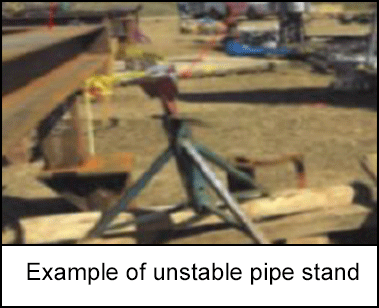

- Procedures for the use of pipe stands, cones, and positioning must be understood.

- The use of pipe stands and cones are meant to be temporary.

- Equipment specifications, such as placement and weight capacity, must be adequate to secure the potential energy of heavy objects.

- Check security of pipe prior to task.

Recommendations:

- Selection of material handling equipment (types of pipe stands, use of adjustable pipe stands, cones and securing methodology) should be appropriate for the intended use.

- Procedures for the safe staging and securement of pipe, and related components, should be made known to workers and validated by regular inspections.

- Before and during tasks, confirm that pipe is stable and secure.

- When planning work include field level hazard assessments that adequately address line of fire and drop hazards.

-

Ask yourself or your crew

How can something like this happen here (e.g. on our site)?

What safety measures (i.e. procedures, controls/barriers) do we have in place to mitigate the risk?

How do we know the risk controls/barriers are working?

What improvements or changes should we make to the procedures, controls/barriers or the way we work?

Add to homescreen

If you want to add this app to home screen tap and then ‘Add to Home Screen’.

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

Multiple incidents of pipe drops occurred in the recent year.

These incidents resulted in injuries to workers that had the potential to be more serious. It also resulted in damage to pipe sections.

Why did it happen?

The incidents all have a common cause, safe staging and securement of pipe at the worksite did not take place.

What did they learn?

- Procedures for the use of pipe stands, cones, and positioning must be understood.

- The use of pipe stands and cones are meant to be temporary.

- Equipment specifications, such as placement and weight capacity, must be adequate to secure the potential energy of heavy objects.

- Check security of pipe prior to task.

Recommendations:

- Selection of material handling equipment (types of pipe stands, use of adjustable pipe stands, cones and securing methodology) should be appropriate for the intended use.

- Procedures for the safe staging and securement of pipe, and related components, should be made known to workers and validated by regular inspections.

- Before and during tasks, confirm that pipe is stable and secure.

- When planning work include field level hazard assessments that adequately address line of fire and drop hazards.

Ask yourself or your crew

How can something like this happen here (e.g. on our site)?

What safety measures (i.e. procedures, controls/barriers) do we have in place to mitigate the risk?

How do we know the risk controls/barriers are working?

What improvements or changes should we make to the procedures, controls/barriers or the way we work?

Published on 10/04/24

1264 Views

Multiple incidents of pipe drops occurred in the recent year. These incidents resulted in injuries to workers and potential for more serious incidents and fatalities. It also resulted in damage to pipe sections. The incidents all have a common cause; safe staging and securement of pipe and worksite did not take place.

Original material courtesy of Energy Safety Canada