-

What happened?

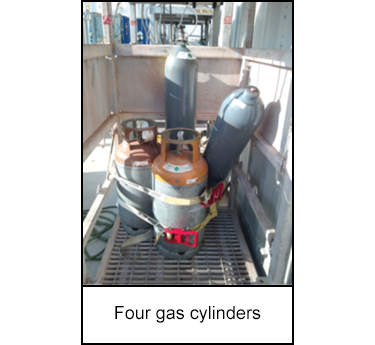

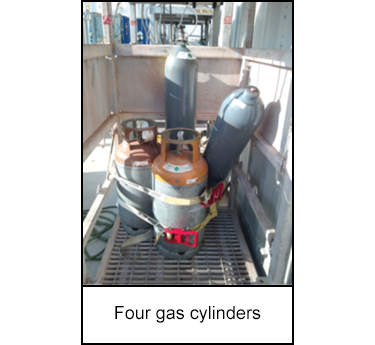

A gas cylinder cage was being lifted out of the floating production facility forward machinery space.

One of two “G” size nitrogen cylinders slipped out of the securing straps and through an opening in the lower back section of the cage.

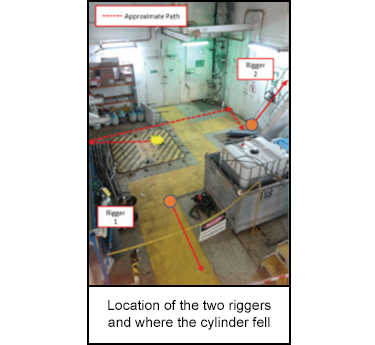

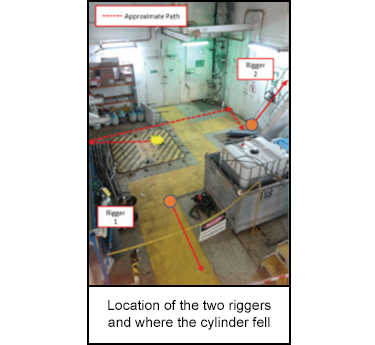

The 60kg (132lbs) cylinder fell 17m (56ft) to the 3rd deck of the machinery space.

The impact ruptured the neck of the cylinder causing it to be propelled within the confines of the machinery space.

Two riggers in the area were not impacted as they were outside of the drop zone. No injuries were sustained.

-

Why did it happen?

The gas cylinder cage supplied by the vendor lacked sufficient internal lashing points to adequately secure “G”, “D” and “E” size gas cylinders together.

The 415mm (16in) gap from the floor of the cage to the first rail was high enough to allow a cylinder to slip through.

-

What did they learn?

Review manufacturer requirements for stacking and securing gas cylinders in cages. Conduct training in the correct securing practices.

Review gas transport cage designs to ensure they can adequately contain gas cylinders should incorrect securing practices occur.

Consider if transport cages or containers for other materials will fail safe in the event of incorrect/inadequate stacking or securing.

-

Ask yourself or your crew

Do you handle gas cylinders in cages at your workplace? Are your cages specifically designed for gas cylinders?

Do you know the correct securing techniques? Are securing points adequate?

If a gas cylinder is not correctly secured, can it fall from the cage?

Do you erect barricades when handling gas cylinders in cages? Are they observed?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A gas cylinder cage was being lifted out of the floating production facility forward machinery space.

One of two “G” size nitrogen cylinders slipped out of the securing straps and through an opening in the lower back section of the cage.

The 60kg (132lbs) cylinder fell 17m (56ft) to the 3rd deck of the machinery space.

The impact ruptured the neck of the cylinder causing it to be propelled within the confines of the machinery space.

Two riggers in the area were not impacted as they were outside of the drop zone. No injuries were sustained.

Why did it happen?

The gas cylinder cage supplied by the vendor lacked sufficient internal lashing points to adequately secure “G”, “D” and “E” size gas cylinders together.

The 415mm (16in) gap from the floor of the cage to the first rail was high enough to allow a cylinder to slip through.

What did they learn?

Review manufacturer requirements for stacking and securing gas cylinders in cages. Conduct training in the correct securing practices.

Review gas transport cage designs to ensure they can adequately contain gas cylinders should incorrect securing practices occur.

Consider if transport cages or containers for other materials will fail safe in the event of incorrect/inadequate stacking or securing.

Ask yourself or your crew

Do you handle gas cylinders in cages at your workplace? Are your cages specifically designed for gas cylinders?

Do you know the correct securing techniques? Are securing points adequate?

If a gas cylinder is not correctly secured, can it fall from the cage?

Do you erect barricades when handling gas cylinders in cages? Are they observed?

While lifting a gas cylinder cage, a nitrogen cylinder slipped out and fell 17m (56ft), rupturing on impact and propelling within the machinery space. Fortunately, no injuries occurred as the riggers were outside the drop zone.

Original material courtesy of Safer Together (Australia)

To access the PDF and PowerPoint versions, please visit https://www.safertogether.com.au/resources/sharing-library/lifting-learning-event-bulletin