-

What happened?

A worker was injured by tongs while working on a drill floor.

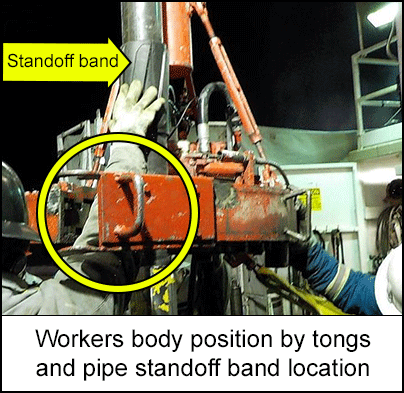

Two workers and a power tong operator placed the power tongs onto the casing string. The power tong door was left wide open and the impacted workers forearm was directly in the bite while holding a standoff* band onto the pipe.

As the worker began to retract his arm in order to close the power tong door, the controls were engaged and workers right forearm was caught in the main drive gear of the power tongs. The gear continued to move before the tong operator stopped the controls.

The worker sustained a serious wound to the flesh, muscle and tendons of his forearm.

* "A device used to keep a tool string in the center of the tubing, casing or wellbore. Tool centralization may be required for several reasons: to prevent the tool from hanging up on obstructions on the wellbore wall, to place fluid efficiently and to avoid excessive standoff.”

Reference: Schlumberger Oilfield Glossary

-

Why did it happen?

The worker held the standoff band by hand while positioned in the bite rather than using

a hands-free alternative.Contributing factors:

- Standoff band position above the workers heads.

- Tong operator did not have a clear view of worker positioned in the line fire.

- The worker was positioned in the bite of the power tongs with the door open.

- The rig and casing crews did not inspect or function test the power tongs prior to use.

- The power tong door interlock pin, cable, and hydraulic bypass system were not functional. The crew decided to use equipment that was in need of repair.

- The power tong controls would not isolate and disengage with the door open.

-

What did they learn?

- Use hands free tool when applicable.

- Develop a “Standard Operating Procedure” for the use, inspection & maintenance of 3rd party equipment.

- Third Party equipment must not be operated unless crew members have been trained and deemed competent.

-

Ask yourself or your crew

- How can something like this happen here (e.g. on our site)?

- What safety measures (i.e. procedures, controls/barriers) do we have in place to mitigate the risk?

- How do we know the risk controls/barriers are working?

- What improvements or changes should we make to the procedures, controls/barriers or the way we work?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A worker was injured by tongs while working on a drill floor.

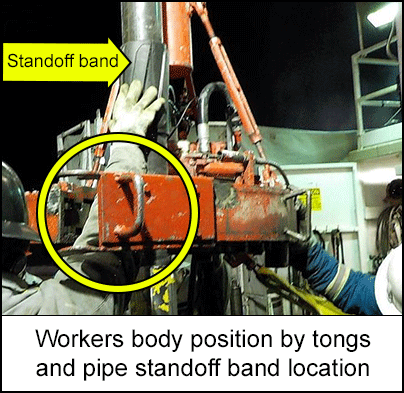

Two workers and a power tong operator placed the power tongs onto the casing string. The power tong door was left wide open and the impacted workers forearm was directly in the bite while holding a standoff* band onto the pipe.

As the worker began to retract his arm in order to close the power tong door, the controls were engaged and workers right forearm was caught in the main drive gear of the power tongs. The gear continued to move before the tong operator stopped the controls.

The worker sustained a serious wound to the flesh, muscle and tendons of his forearm.

* "A device used to keep a tool string in the center of the tubing, casing or wellbore. Tool centralization may be required for several reasons: to prevent the tool from hanging up on obstructions on the wellbore wall, to place fluid efficiently and to avoid excessive standoff.”

Reference: Schlumberger Oilfield Glossary

Why did it happen?

The worker held the standoff band by hand while positioned in the bite rather than using

a hands-free alternative.

Contributing factors:

- Standoff band position above the workers heads.

- Tong operator did not have a clear view of worker positioned in the line fire.

- The worker was positioned in the bite of the power tongs with the door open.

- The rig and casing crews did not inspect or function test the power tongs prior to use.

- The power tong door interlock pin, cable, and hydraulic bypass system were not functional. The crew decided to use equipment that was in need of repair.

- The power tong controls would not isolate and disengage with the door open.

What did they learn?

- Use hands free tool when applicable.

- Develop a “Standard Operating Procedure” for the use, inspection & maintenance of 3rd party equipment.

- Third Party equipment must not be operated unless crew members have been trained and deemed competent.

Ask yourself or your crew

- How can something like this happen here (e.g. on our site)?

- What safety measures (i.e. procedures, controls/barriers) do we have in place to mitigate the risk?

- How do we know the risk controls/barriers are working?

- What improvements or changes should we make to the procedures, controls/barriers or the way we work?

Two workers and a power tong operator placed the power tongs onto the casing string. The power tong door was left wide open and the impacted workers forearm was directly in the bite while holding a standoff band onto the pipe. As the worker began to retract his arm in order to close the power tong door, the controls were engaged and workers right forearm was caught in the main drive gear of the power tongs. The gear continued to move before the tong operator stopped the controls. The worker sustained a serious wound to the flesh, muscle and tendons of his forearm.

Original material courtesy of Energy Safety Canada