-

What happened?

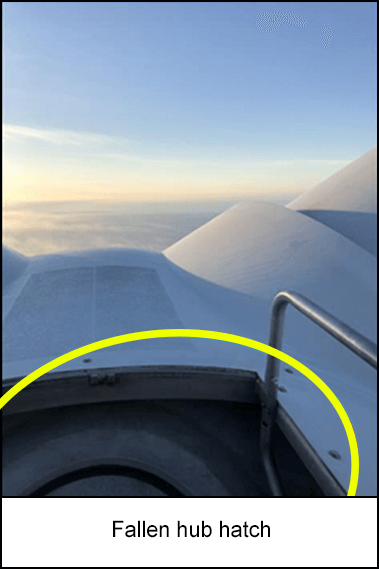

During a maintenance task to exchange the main bearing and remove blades on a wind turbine, a missing lower interior hub hatch was discovered.

As the exterior hatches had been removed previously on this turbine type, there was no mechanism to secure a loose interior hatch.

To continue to work safely, the team of technicians removed a hatch from the 12 o'clock position and used it to plug the empty lower hatch.

While the technicians were removing the blades inside the hub, the second opposite hub hatch fell from the turbine into the water.

-

Why did it happen?

The incident was caused by several factors:

- No or insufficient pull/push test was conducted when refitting the hub hatch, and there was no cross-check with another technician.

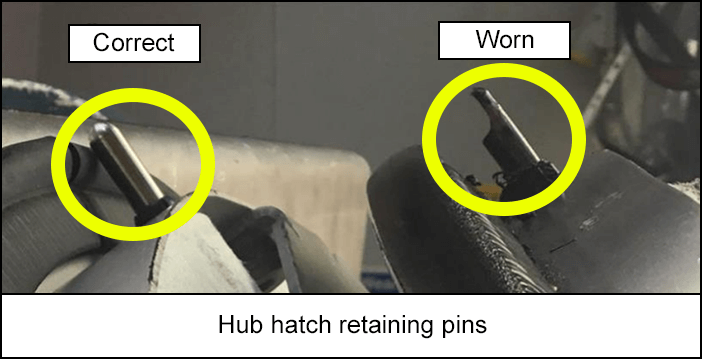

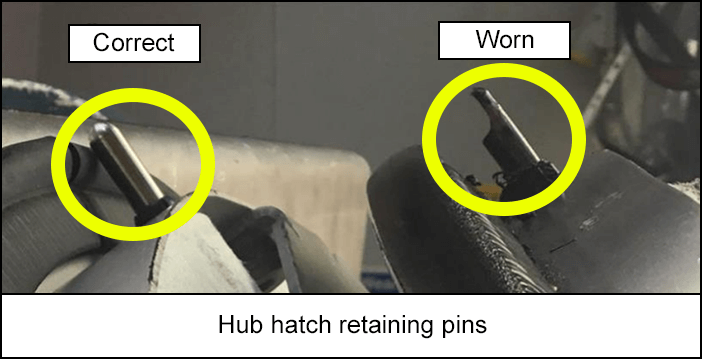

- It was possible to lock the handle of the hub hatch without the hub pins being properly located in the hub receiving groove.

- The design lacked a visual indicator to confirm that the hub hatch was correctly positioned and locked in place by retaining pins.

- The work package did not adequately emphasize the risk of dropped hub hatches if they were not fitted correctly and the need for a push/pull test.

- The aging of the hub hatch seals and the subsequent motion/wear were not anticipated as operational problems during the design stage.

-

What did they learn?

There is a possibility of incorrectly fitting the platform hub hatch and closing the locking handle without the hatch being properly inserted into the hub opening, preventing the pins from engaging and locking into the hub.

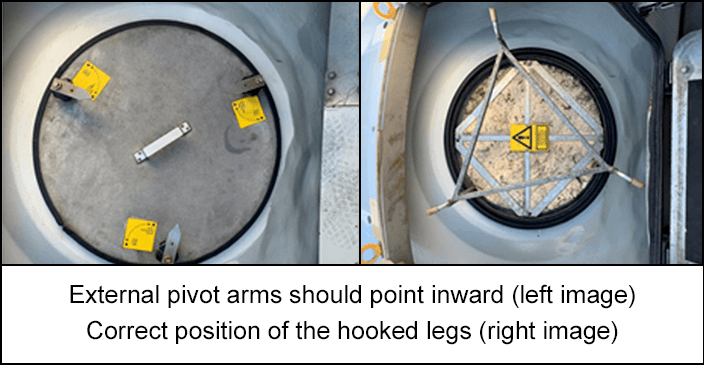

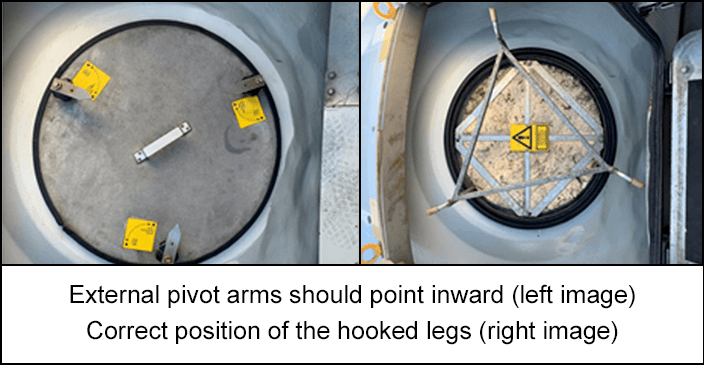

To ensure proper alignment, the external pivot arms should be directed inward, positioning the hooked legs as shown in the image. Below the pivot arms, there are black locking nuts that need to be fully tightened.

Missing hatches during the operation of a wind turbine generator (WTG) are more common than hatches being dropped while personnel are present.

-

Ask yourself or your crew

How do you ensure that hub hatches are correctly positioned and locked during maintenance tasks? What challenges do you face in this process?

What additional safety measures or visual indicators do you think could be implemented to reduce the risk of incorrectly fitting hub hatches?

What improvements or changes should we make to the procedures, controls/barriers, or the way we work?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

During a maintenance task to exchange the main bearing and remove blades on a wind turbine, a missing lower interior hub hatch was discovered.

As the exterior hatches had been removed previously on this turbine type, there was no mechanism to secure a loose interior hatch.

To continue to work safely, the team of technicians removed a hatch from the 12 o'clock position and used it to plug the empty lower hatch.

While the technicians were removing the blades inside the hub, the second opposite hub hatch fell from the turbine into the water.

Why did it happen?

The incident was caused by several factors:

- No or insufficient pull/push test was conducted when refitting the hub hatch, and there was no cross-check with another technician.

- It was possible to lock the handle of the hub hatch without the hub pins being properly located in the hub receiving groove.

- The design lacked a visual indicator to confirm that the hub hatch was correctly positioned and locked in place by retaining pins.

- The work package did not adequately emphasize the risk of dropped hub hatches if they were not fitted correctly and the need for a push/pull test.

- The aging of the hub hatch seals and the subsequent motion/wear were not anticipated as operational problems during the design stage.

What did they learn?

There is a possibility of incorrectly fitting the platform hub hatch and closing the locking handle without the hatch being properly inserted into the hub opening, preventing the pins from engaging and locking into the hub.

To ensure proper alignment, the external pivot arms should be directed inward, positioning the hooked legs as shown in the image. Below the pivot arms, there are black locking nuts that need to be fully tightened.

Missing hatches during the operation of a wind turbine generator (WTG) are more common than hatches being dropped while personnel are present.

Ask yourself or your crew

How do you ensure that hub hatches are correctly positioned and locked during maintenance tasks? What challenges do you face in this process?

What additional safety measures or visual indicators do you think could be implemented to reduce the risk of incorrectly fitting hub hatches?

What improvements or changes should we make to the procedures, controls/barriers, or the way we work?

During a maintenance task to exchange the main bearing and remove blades on a wind turbine, a missing lower interior hub hatch was discovered. To continue to work safely, the team of technicians removed a hatch from the 12 o'clock position and used it to plug the empty lower hatch. While the technicians were removing the blades inside the hub, the second opposite hub hatch fell from the turbine into the water.