-

What happened?

Repairs were completed on a wind turbine blade.

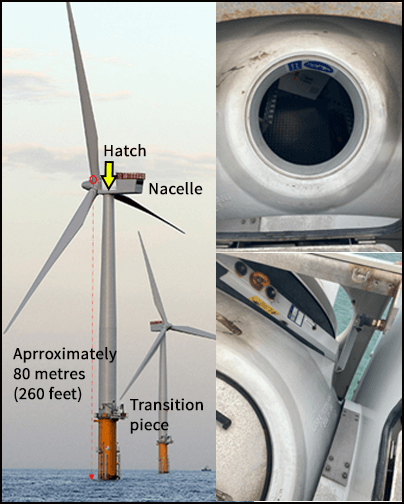

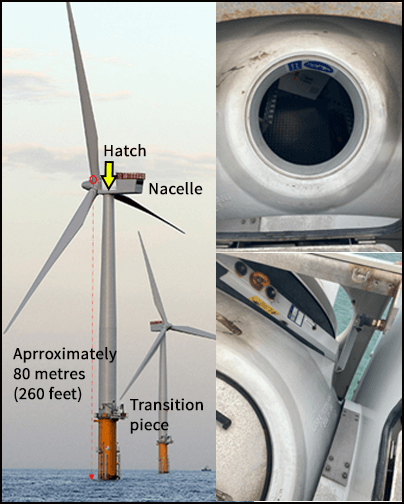

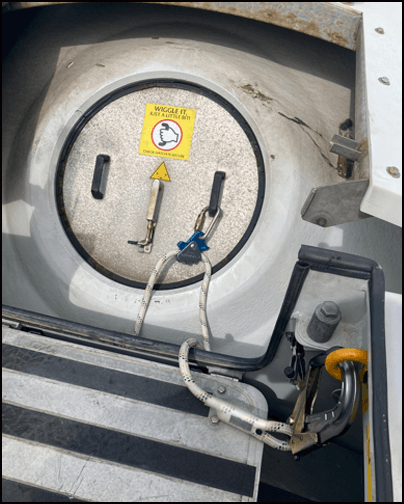

After restart, an inspection hatch weighing 5 kg (11 lbs.) dropped approximately 80 metres (260 ft.) to the sea.

No personnel were injured. The hatch could have impacted a technician standing on the transition piece below or personnel onboard the crew transfer vessel (CTV) as the exclusion zone established during repairs was no longer in force.

A safety stand down review was conducted.

-

Why did it happen?

The requirements of the approved written procedure (AWP) were not correctly adhered to:

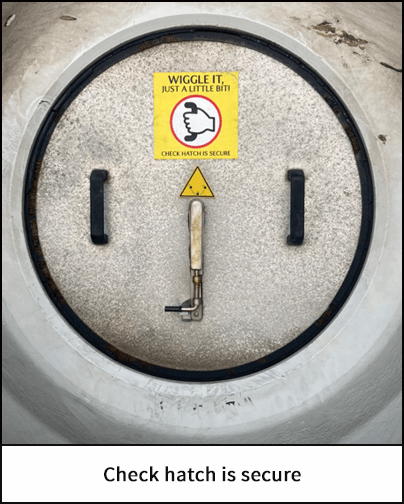

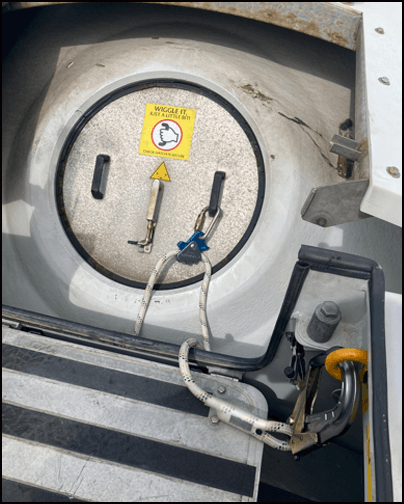

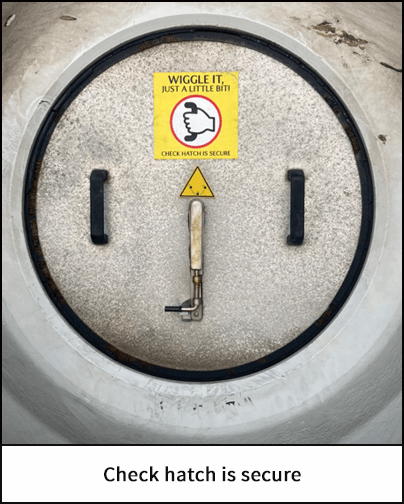

- The hub hatch was not correctly placed back after use during the repairs.

- The integrity checks were not carried out by the supervisor.

The procedures for removal and replacement were not detailed enough relative to the potential severity of a failure.

There was no designed permanent method to stop the hatch from falling.

Contractors’ understanding of the procedures (including stop work authority) was not assessed properly.

-

What did they learn?

Identify the requirement of putting back hatches in their place after use as a safety critical task within the procedure.

Consider a mechanical retrofit to ensure these types of hatches cannot fall.

Establish a safe zone under the blades when restarting after inspection or maintenance.

Assess the understanding of procedures amongst all personnel on site, including contractors.

-

Ask yourself or your crew

How can something similar happen here? Think of all types of hatches, including for larger turbines.

What steps should we follow when working at height and moving hatches and equipment?

What would be the consequences of something like this occurring on our site? How do we communicate this risk?

What safety measures (i.e. procedures, controls/barriers) do we have in place to mitigate the risk?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

Repairs were completed on a wind turbine blade.

After restart, an inspection hatch weighing 5 kg (11 lbs.) dropped approximately 80 metres (260 ft.) to the sea.

No personnel were injured. The hatch could have impacted a technician standing on the transition piece below or personnel onboard the crew transfer vessel (CTV) as the exclusion zone established during repairs was no longer in force.

A safety stand down review was conducted.

Why did it happen?

The requirements of the approved written procedure (AWP) were not correctly adhered to:

- The hub hatch was not correctly placed back after use during the repairs.

- The integrity checks were not carried out by the supervisor.

The procedures for removal and replacement were not detailed enough relative to the potential severity of a failure.

There was no designed permanent method to stop the hatch from falling.

Contractors’ understanding of the procedures (including stop work authority) was not assessed properly.

What did they learn?

Identify the requirement of putting back hatches in their place after use as a safety critical task within the procedure.

Consider a mechanical retrofit to ensure these types of hatches cannot fall.

Establish a safe zone under the blades when restarting after inspection or maintenance.

Assess the understanding of procedures amongst all personnel on site, including contractors.

Ask yourself or your crew

How can something similar happen here? Think of all types of hatches, including for larger turbines.

What steps should we follow when working at height and moving hatches and equipment?

What would be the consequences of something like this occurring on our site? How do we communicate this risk?

What safety measures (i.e. procedures, controls/barriers) do we have in place to mitigate the risk?

Repairs were completed on a wind turbine blade. After restart, an inspection hatch weighing dropped approximately 80 metres (260 ft.) to the sea. No personnel were injured. The hatch could have impacted a technician standing on the transition piece below or personnel onboard the crew transfer vessel (CTV) as the exclusion zone established during repairs was no longer in force.