-

What happened?

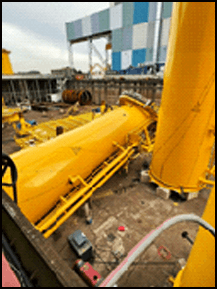

A transition piece (TP) was prepared for load out.

Shortly after the start of the lift, the internal system detected a difference in the loads between the three hooks, and it was automatically stopped.

Hook 1 was not able to hold the load which meant it descended, while hook 2 and 3 stayed at the same height.

This caused the transition piece to fall into a vertical unstable position.

The spreader then came down and pulled the transition piece into a horizontal position on the cellar deck platform.

-

Why did it happen?

There was a mechanical failure in hook 1, which allowed the load to descend.

Although the maintenance of the overhead crane was performed by an experienced external company and witnessed by third party inspection:

- no full load test was performed on the system

- there were no predefined points for inspection after or during maintenance

- the technician did not have sufficient technical knowledge

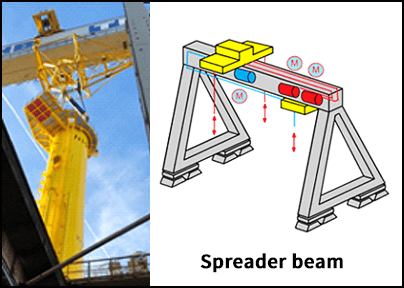

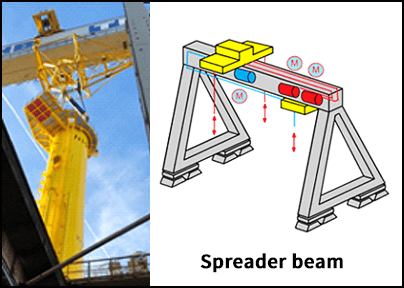

The risk of the spreader beam falling was not considered.

-

What did they learn?

An extra set of safety breaks should be fitted on the rotors (working as a parallel safety option).

Full load tests should be undertaken after adaptation or replacement of critical components.

Ensure that the basis of the support system is large enough, so if there is movement in the TP, the support does not fall.

Maintenance procedures should be reviewed regularly to ensure that they are fit for purpose and suitable for any new or modified task carried out by the crane.

-

Ask yourself or your crew

What controls do we have in place to prevent this from happening on our site? How do we know this will be effective?

Why should we have predefined inspection points after maintenance activities?

What other hazards should you look out for during lifting operations on transition pieces?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A transition piece (TP) was prepared for load out.

Shortly after the start of the lift, the internal system detected a difference in the loads between the three hooks, and it was automatically stopped.

Hook 1 was not able to hold the load which meant it descended, while hook 2 and 3 stayed at the same height.

This caused the transition piece to fall into a vertical unstable position.

The spreader then came down and pulled the transition piece into a horizontal position on the cellar deck platform.

Why did it happen?

There was a mechanical failure in hook 1, which allowed the load to descend.

Although the maintenance of the overhead crane was performed by an experienced external company and witnessed by third party inspection:

- no full load test was performed on the system

- there were no predefined points for inspection after or during maintenance

- the technician did not have sufficient technical knowledge

The risk of the spreader beam falling was not considered.

What did they learn?

An extra set of safety breaks should be fitted on the rotors (working as a parallel safety option).

Full load tests should be undertaken after adaptation or replacement of critical components.

Ensure that the basis of the support system is large enough, so if there is movement in the TP, the support does not fall.

Maintenance procedures should be reviewed regularly to ensure that they are fit for purpose and suitable for any new or modified task carried out by the crane.

Ask yourself or your crew

What controls do we have in place to prevent this from happening on our site? How do we know this will be effective?

Why should we have predefined inspection points after maintenance activities?

What other hazards should you look out for during lifting operations on transition pieces?

A transition piece (TP) was prepared for load out. Shortly after the start of the lift, the internal system detected a difference in the loads between the three hooks. Following a sequence of events, the transition piece to fell on the cellar deck platform.