-

What happened?

During shutdown, a work group arrived at a job site to activate a work permit.

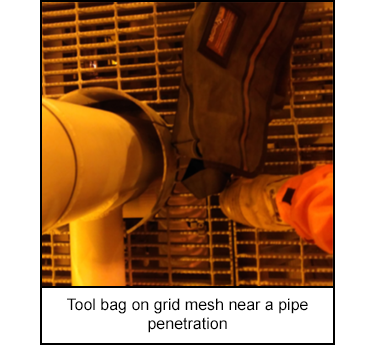

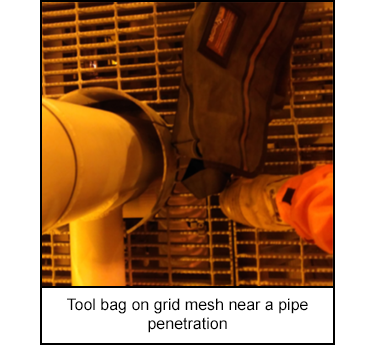

When arriving, a worker placed their tool bag down on grid mesh which resulted in a 1.5 kg (3.3 lbs) pinch bar slipping out of the tool bag and falling through a pipe penetration in the grid mesh.

The pinch bar fell approximately 20m (66ft), striking structural steel before landing on the ground near another worker.

The area where the pinch bar landed was a thoroughfare for multiple work groups.

-

Why did it happen?

The bag used to transport tools was not large enough to fully contain the pinch bar.

The bag was placed near a pipe penetration (dropped object hazard area without protection).

Dropped object matting had not yet been installed at the work location, as the work permit had not yet been activated.

-

What did they learn?

Adequately secure tools being transported to work site by effective means to fully contain contents (e.g. tool bags, backpacks, or alternative mechanical means).

Procure and promote sitewide use of larger bags to fully contain tools.

Procure and install rubber guards on pinch bars to reduce the likelihood of the tool falling between gaps or grid-mesh.

Initiate sitewide standdown and conduct site inspections to review dropped object risks and controls.

-

Ask yourself or your crew

Do you perform regular inspections of equipment and work areas at your work site to identify dropped object hazard areas?

When a potential dropped object is identified, do you and your work mates discuss the “what if” question? (e.g. What if that falls - could it hit people or plant? What is the worst outcome if it did?)

When an actual or potential dropped object is identified, do you report it to your supervisor?

What do you do at your worksite to prevent non-secured tools and equipment, and small pieces (e.g. nuts and bolts), from slipping through openings such as walkway gratings and deck penetrations?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

During shutdown, a work group arrived at a job site to activate a work permit.

When arriving, a worker placed their tool bag down on grid mesh which resulted in a 1.5 kg (3.3 lbs) pinch bar slipping out of the tool bag and falling through a pipe penetration in the grid mesh.

The pinch bar fell approximately 20m (66ft), striking structural steel before landing on the ground near another worker.

The area where the pinch bar landed was a thoroughfare for multiple work groups.

Why did it happen?

The bag used to transport tools was not large enough to fully contain the pinch bar.

The bag was placed near a pipe penetration (dropped object hazard area without protection).

Dropped object matting had not yet been installed at the work location, as the work permit had not yet been activated.

What did they learn?

Adequately secure tools being transported to work site by effective means to fully contain contents (e.g. tool bags, backpacks, or alternative mechanical means).

Procure and promote sitewide use of larger bags to fully contain tools.

Procure and install rubber guards on pinch bars to reduce the likelihood of the tool falling between gaps or grid-mesh.

Initiate sitewide standdown and conduct site inspections to review dropped object risks and controls.

Ask yourself or your crew

Do you perform regular inspections of equipment and work areas at your work site to identify dropped object hazard areas?

When a potential dropped object is identified, do you and your work mates discuss the “what if” question? (e.g. What if that falls - could it hit people or plant? What is the worst outcome if it did?)

When an actual or potential dropped object is identified, do you report it to your supervisor?

What do you do at your worksite to prevent non-secured tools and equipment, and small pieces (e.g. nuts and bolts), from slipping through openings such as walkway gratings and deck penetrations?

During a shutdown, a worker’s tool bag was placed on grid mesh, causing a 1.5 kg (3.3 lbs) pinch bar to fall 20 meters (66 feet) through a pipe penetration. The bar struck structural steel before landing near another worker in a busy path.

Original material courtesy of Safer Together (Australia)

To access the PDF and PowerPoint versions, please visit https://www.safertogether.com.au/resources/sharing-library/working-at-height-dropped-object-learning-event-bulletin