-

What happened?

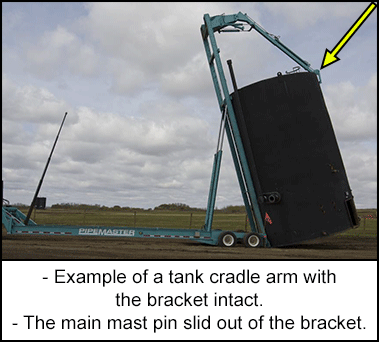

A 1,000-barrel tank was being moved into place when the cradle arm bracket failed.

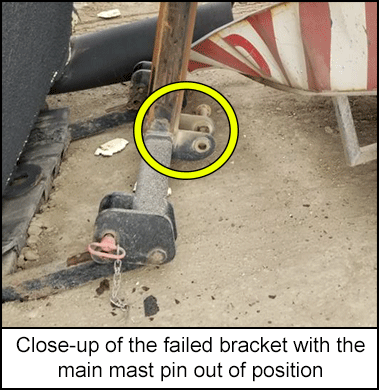

The bracket was held in place by the main mast pin, which was secured with a cotter pin. The cotter pin broke, allowing the main mast pin to slide out of place. As a result, the tank slid off the cradle, fell to the ground, and landed on its side, damaging the tank.

No injuries occurred.

-

Why did it happen?

The cotter pin was either not put in place correctly, or shifted during the move.

Contributing factors:

- No previous inspection records were available.

- Equipment was not visually inspected prior to use.

- Cotter pins used in this application are prone to damage while being transported.

- The cotter pin used may not have been made from the correct material for the equipment

-

What did they learn?

- Revise existing policies/procedures to include specific equipment inspection points prior

to use. - Cotter pin holding the main mast should be replaced with a grade 8 capture pin. (Note: the manufacturer of the equipment has not suggested an upgrade to the cotter pin design, however, it is possible that without frequent inspections of the current cotter pin design, this failure could happen again).

- Revise existing policies/procedures to include specific equipment inspection points prior

-

Ask yourself or your crew

- How can something like this happen here (e.g. on our site)?

- What safety measures (i.e. procedures, controls/barriers) do we have in place to mitigate the risk?

- How do we know the risk controls/barriers are working?

- What improvements or changes should we make to the procedures, controls/barriers or the way we work?

Add to homescreen

If you want to add this app to home screen tap and then ‘Add to Home Screen’.

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A 1,000-barrel tank was being moved into place when the cradle arm bracket failed.

The bracket was held in place by the main mast pin, which was secured with a cotter pin. The cotter pin broke, allowing the main mast pin to slide out of place. As a result, the tank slid off the cradle, fell to the ground, and landed on its side, damaging the tank.

No injuries occurred.

Why did it happen?

The cotter pin was either not put in place correctly, or shifted during the move.

Contributing factors:

- No previous inspection records were available.

- Equipment was not visually inspected prior to use.

- Cotter pins used in this application are prone to damage while being transported.

- The cotter pin used may not have been made from the correct material for the equipment

What did they learn?

- Revise existing policies/procedures to include specific equipment inspection points prior

to use. - Cotter pin holding the main mast should be replaced with a grade 8 capture pin. (Note: the manufacturer of the equipment has not suggested an upgrade to the cotter pin design, however, it is possible that without frequent inspections of the current cotter pin design, this failure could happen again).

Ask yourself or your crew

- How can something like this happen here (e.g. on our site)?

- What safety measures (i.e. procedures, controls/barriers) do we have in place to mitigate the risk?

- How do we know the risk controls/barriers are working?

- What improvements or changes should we make to the procedures, controls/barriers or the way we work?

Published on 20/04/23

1425 Views

A 1,000-barrel tank was being moved into place when the cradle arm bracket failed. The bracket was held in place by the main mast pin (which was secured with a cotter pin) and the cotter pin broke, allowing the main mast pin to slide out of place. As a result, the tank slid off the cradle, fell to the ground, and landed on its slide, damaging the tank. No injuries occurred.

Original material courtesy of Energy Safety Canada