-

What happened?

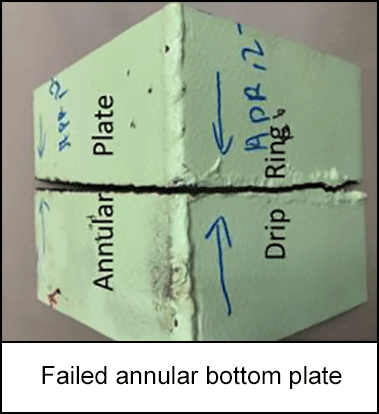

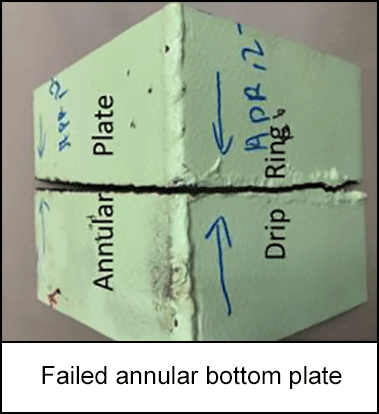

During a visual inspection of a product storage tank, a trace of solidified product was identified, indicating a crack along the drip ring and the annular bottom plate.

The tank specification called for the steel to have a minimum design metal temperature (MDMT) of -40 C but the material became brittle at lower temperatures (-15 C and below), resulting in a crack.

-

Why did it happen?

- The supplier substituted a higher quality steel product not knowing that it had a different MDMT.

- A risk assessment using an international standard, such as API 650 Welded Tanks for Oil Storage, was not performed.

- The tank material vendors and internal company supply chain both assumed the appropriate tests were conducted, and specifications were met.

-

What did they learn?

- Ensure that any steel material tank substitutions are risk assessed in relation to MDMT as part of a management of change process.

- Material vendors and supply chain teams must communicate clearly and in detail about material specifications and design requirements.

- Use the tools provided in the international standards (charts, grades of metals, etc.) to ensure material specifications are met.

- Always consider the impact of temperature variability in the selection or substitution of materials.

-

Ask yourself or your crew

- What is the potential for something similar to happen at my work site?

- How do we verify that new and existing materials meet design specifications?

- Are integrity checks in relation to material specifications part of the existing process?

- What are the potential consequences of not adhering to material specifications in changing temperatures/weather conditions?

- What systems do we have in place for proactive adherence to material specifications? How can we improve?

Add to homescreen

If you want to add this app to home screen tap and then ‘Add to Home Screen’.

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

During a visual inspection of a product storage tank, a trace of solidified product was identified, indicating a crack along the drip ring and the annular bottom plate.

The tank specification called for the steel to have a minimum design metal temperature (MDMT) of -40 C but the material became brittle at lower temperatures (-15 C and below), resulting in a crack.

Why did it happen?

- The supplier substituted a higher quality steel product not knowing that it had a different MDMT.

- A risk assessment using an international standard, such as API 650 Welded Tanks for Oil Storage, was not performed.

- The tank material vendors and internal company supply chain both assumed the appropriate tests were conducted, and specifications were met.

What did they learn?

- Ensure that any steel material tank substitutions are risk assessed in relation to MDMT as part of a management of change process.

- Material vendors and supply chain teams must communicate clearly and in detail about material specifications and design requirements.

- Use the tools provided in the international standards (charts, grades of metals, etc.) to ensure material specifications are met.

- Always consider the impact of temperature variability in the selection or substitution of materials.

Ask yourself or your crew

- What is the potential for something similar to happen at my work site?

- How do we verify that new and existing materials meet design specifications?

- Are integrity checks in relation to material specifications part of the existing process?

- What are the potential consequences of not adhering to material specifications in changing temperatures/weather conditions?

- What systems do we have in place for proactive adherence to material specifications? How can we improve?

Published on 09/06/23

1679 Views

During a visual inspection of a product storage tank, a trace of solidified product was identified, indicating a crack along the drip ring and the annular bottom plate. The tank specification called for the steel to have a minimum design metal temperature (MDMT) but the material became brittle at lower temperatures, resulting in a crack.

Original material courtesy of Energy Safety Canada