-

What happened?

A silencer (muffler) is a device for reducing noise. It is often found on steam vents to atmosphere (e.g. boiler startup vents, blowdown systems, and pressure relief valve discharges).

A 17 lbs (8 kg) internal component of a steam silencer was ejected through a vent stack, during start-up of a steam boiler. The internal component landed in a parking lot 500 ft (152 m) away. No injuries occurred.

This and 14 other incidents involving silencers were reviewed for broader learnings.

-

Why did it happen?

Incidents involving silencers mostly occurred during start-up and shutdown. The most common type of silencer involved was on a boiler. The most common failure mechanism is corrosion, and the most common consequence is ejection of silencer internals.

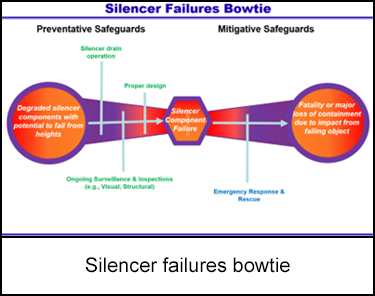

Key causal factors are:

- Material selection – carbon steel components exposed to the atmosphere.

- Inspection frequency – long service life with no/limited inspection & maintenance.

- Drain operations – inadequate silencer drain operation allowing water to collect, causing blockage/corrosion.

-

What did they learn?

Appropriate drain operation – ensure water does not collect within silencer.

Inspection – identify silencer internal and structural degradation and correct with timely maintenance.

Proper design (material selection) – follow appropriate company practices (original and retrofits).

Emergency response – Consider that timely emergency responses can minimise consequences.

-

Ask yourself or your crew

How do you know if silencer design includes appropriate material selection (e.g. silencer internals typically constructed of stainless steel or galvanised carbon steel materials)?

What is the location of atmospheric vent silencers onsite? Are these silencers documented on piping and instrumentation diagrams (P&IDs)?

Do you periodically physically inspect silencer internals (e.g. via borescope) and structural components for degradation?

Do you monitor silencer pressure drop to ensure silencer operating within design parameters?

Does your site operator rounds periodically check silencer drain lines for water accumulation / free flowing? Are you aware that a blocked drain can allow backup of water within the silencer body and/or the upstream piping and that, in these circumstances, sudden release of high pressure steam can result in a high energy water slug can carry enough impingement momentum to cause sudden and catastrophic failure of the silencer internal components?

Does your site winterisation plan include checks of the silencer (e.g. damage from freeze, frozen/plugged drain and/or silencer internals)?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A silencer (muffler) is a device for reducing noise. It is often found on steam vents to atmosphere (e.g. boiler startup vents, blowdown systems, and pressure relief valve discharges).

A 17 lbs (8 kg) internal component of a steam silencer was ejected through a vent stack, during start-up of a steam boiler. The internal component landed in a parking lot 500 ft (152 m) away. No injuries occurred.

This and 14 other incidents involving silencers were reviewed for broader learnings.

Why did it happen?

Incidents involving silencers mostly occurred during start-up and shutdown. The most common type of silencer involved was on a boiler. The most common failure mechanism is corrosion, and the most common consequence is ejection of silencer internals.

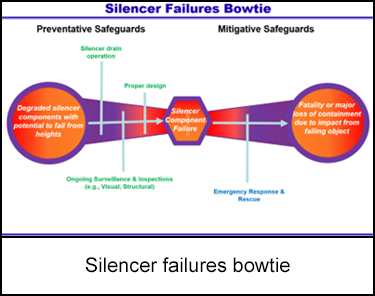

Key causal factors are:

- Material selection – carbon steel components exposed to the atmosphere.

- Inspection frequency – long service life with no/limited inspection & maintenance.

- Drain operations – inadequate silencer drain operation allowing water to collect, causing blockage/corrosion.

What did they learn?

Appropriate drain operation – ensure water does not collect within silencer.

Inspection – identify silencer internal and structural degradation and correct with timely maintenance.

Proper design (material selection) – follow appropriate company practices (original and retrofits).

Emergency response – Consider that timely emergency responses can minimise consequences.

Ask yourself or your crew

How do you know if silencer design includes appropriate material selection (e.g. silencer internals typically constructed of stainless steel or galvanised carbon steel materials)?

What is the location of atmospheric vent silencers onsite? Are these silencers documented on piping and instrumentation diagrams (P&IDs)?

Do you periodically physically inspect silencer internals (e.g. via borescope) and structural components for degradation?

Do you monitor silencer pressure drop to ensure silencer operating within design parameters?

Does your site operator rounds periodically check silencer drain lines for water accumulation / free flowing? Are you aware that a blocked drain can allow backup of water within the silencer body and/or the upstream piping and that, in these circumstances, sudden release of high pressure steam can result in a high energy water slug can carry enough impingement momentum to cause sudden and catastrophic failure of the silencer internal components?

Does your site winterisation plan include checks of the silencer (e.g. damage from freeze, frozen/plugged drain and/or silencer internals)?

A 17 lbs (8 kg) internal component of a steam silencer was ejected through a vent stack, during start-up of a steam boiler, and landed in a parking lot 500 ft (152 m) away. No injuries occurred.