-

What happened?

A steam hose was placed inside a wellhead shack to heat and thaw equipment.

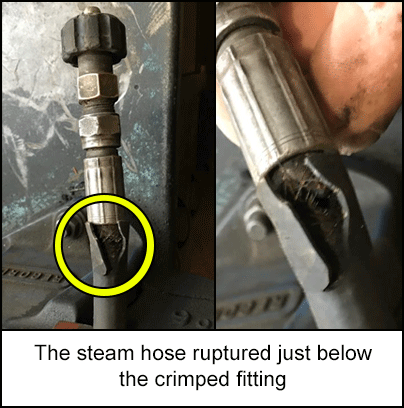

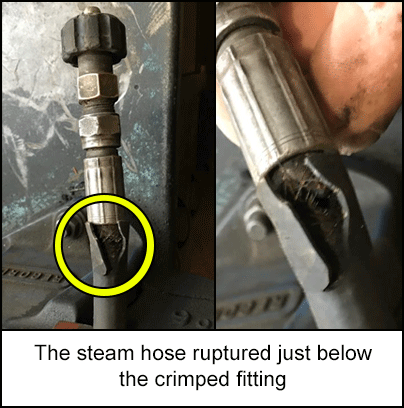

The worker wanted to check the pressure gauge on a piece of equipment in the shack, and was unable to clearly see the gauge because of the accumulation of steam. The worker tugged on the hose to remove it from the shack, unaware that the hose had ruptured at a crimped fitting. As he tugged the hose, it bounced toward the worker, sending steam up the worker’s jacket sleeve and scalding the skin.

The worker sustained a minor burn on the forearm. First aid was administered immediately, and the worker was able to resume work. If the hose had turned towards the worker’s face, the injuries could have been much more severe.

-

Why did it happen?

- The steam hose ruptured while in use.

Contributing factors:

- The worker removed the hose from the shack without turning off the steam first.

- The position of the hose within the wellhead shack may have contributed to its failure. Bending a hose sharply by a coupling could result in weakening the hose and causing a rupture.

-

What did they learn?

- Steam hoses have a finite life and they gradually deteriorate; hoses should be inspected before and after each use.

- Use manufacturer standards for inspection and replacement. Hoses with any damage should be removed from service. Inspection of hoses could include: looking for cover blisters, worn spots, kinking, basketing, cuts and gouges, cover cracking and lumps.

- Check tightness of clamps and valves before and after each use.

- Avoid extreme flexing of hoses near couplings.

- Consider turning off steam to move hoses.

- Appropriate personal protective equipment should be worn when working with steam.

- Consider using a shut off valve between the steam source and the wand.

-

Ask yourself or your crew

How can we prevent something like this from happening here?

What are other risks are associated with forklift operations? How can you mitigate those risks at your work site?

What safety recommendations should be included in the operational instructions?

How can we, as a company, implement a practical training plan that focuses on the job position, and make sure pedestrians are safer from forklifts in the future?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A steam hose was placed inside a wellhead shack to heat and thaw equipment.

The worker wanted to check the pressure gauge on a piece of equipment in the shack, and was unable to clearly see the gauge because of the accumulation of steam. The worker tugged on the hose to remove it from the shack, unaware that the hose had ruptured at a crimped fitting. As he tugged the hose, it bounced toward the worker, sending steam up the worker’s jacket sleeve and scalding the skin.

The worker sustained a minor burn on the forearm. First aid was administered immediately, and the worker was able to resume work. If the hose had turned towards the worker’s face, the injuries could have been much more severe.

Why did it happen?

- The steam hose ruptured while in use.

Contributing factors:

- The worker removed the hose from the shack without turning off the steam first.

- The position of the hose within the wellhead shack may have contributed to its failure. Bending a hose sharply by a coupling could result in weakening the hose and causing a rupture.

What did they learn?

- Steam hoses have a finite life and they gradually deteriorate; hoses should be inspected before and after each use.

- Use manufacturer standards for inspection and replacement. Hoses with any damage should be removed from service. Inspection of hoses could include: looking for cover blisters, worn spots, kinking, basketing, cuts and gouges, cover cracking and lumps.

- Check tightness of clamps and valves before and after each use.

- Avoid extreme flexing of hoses near couplings.

- Consider turning off steam to move hoses.

- Appropriate personal protective equipment should be worn when working with steam.

- Consider using a shut off valve between the steam source and the wand.

Ask yourself or your crew

How can we prevent something like this from happening here?

What are other risks are associated with forklift operations? How can you mitigate those risks at your work site?

What safety recommendations should be included in the operational instructions?

How can we, as a company, implement a practical training plan that focuses on the job position, and make sure pedestrians are safer from forklifts in the future?

In a wellhead shack, a steam hose was placed for equipment heating and thawing. The worker attempted to check the pressure gauge but struggled due to steam obstruction. Unaware of a hose rupture, the worker pulled it, causing steam to scald their forearm when it rebounded.

Original material courtesy of Energy Safety Canada