-

What happened?

The crew was lowering a slant rig mast and heard a ‘pop’.

The mast was leaning towards the side of the carrier.

-

Why did it happen?

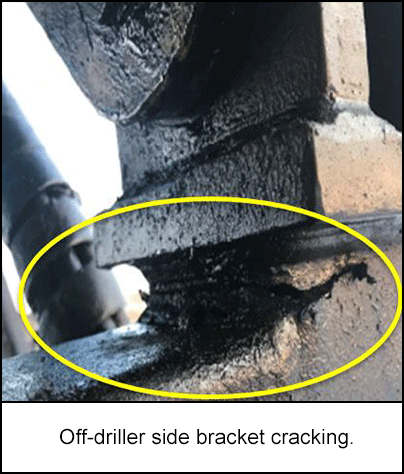

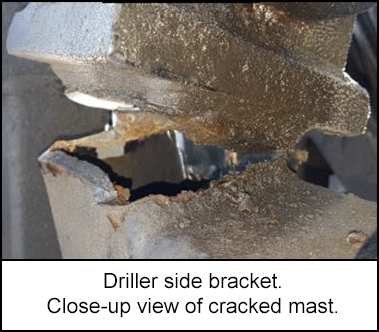

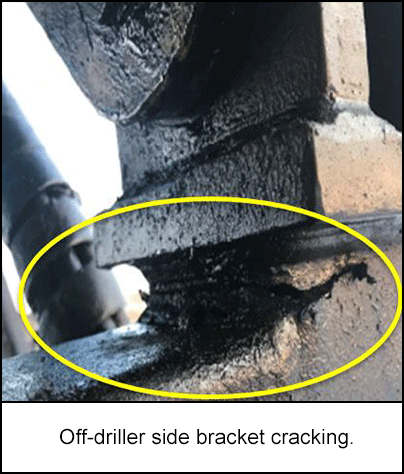

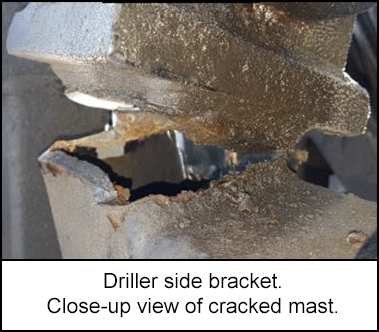

A third-party inspection revealed two weld failures at the brackets that pin the mast to the A-frame.

Contributing factors:

- Previous engineering quality control, assurance and repair added to the difficulty for inspection.

- Workers required a higher level of inspection experience to recognize cracking in the welds.

-

What did they learn?

Regular Level I and II inspections as per the CAODC recommended practice did not include inspection the welded areas under the mast brackets.

Some corrective actions were taken:

The company had been following the CAODC Canadian Well Servicing Industry; Recommended Practice 3.0: Inspection and Certification of Masts (SR), including the hours of service inspection intervals. More frequent Level III inspections may have brought attention to cracks in the mast by the A-frame.

The company focused on the following actions:

- Engineers certified in Level III and higher inspections will train field supervisors, rig managers and drillers for awareness of overall component inspections.

- Rig managers and drillers will continue to perform Level II inspections of entire mast structures, paying special attention to the carrier, ears, mast derrick pins and A-frame.

-

Ask yourself or your crew

- How can something like this happen here (e.g. on our site)?

- What safety measures (i.e. procedures, controls/barriers) do we have in place to mitigate the risk?

- How do we know the risk controls/barriers are working?

- What improvements or changes should we make to the procedures, controls/barriers or the way we work?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

The crew was lowering a slant rig mast and heard a ‘pop’.

The mast was leaning towards the side of the carrier.

Why did it happen?

A third-party inspection revealed two weld failures at the brackets that pin the mast to the A-frame.

Contributing factors:

- Previous engineering quality control, assurance and repair added to the difficulty for inspection.

- Workers required a higher level of inspection experience to recognize cracking in the welds.

What did they learn?

Regular Level I and II inspections as per the CAODC recommended practice did not include inspection the welded areas under the mast brackets.

Some corrective actions were taken:

The company had been following the CAODC Canadian Well Servicing Industry; Recommended Practice 3.0: Inspection and Certification of Masts (SR), including the hours of service inspection intervals. More frequent Level III inspections may have brought attention to cracks in the mast by the A-frame.

The company focused on the following actions:

- Engineers certified in Level III and higher inspections will train field supervisors, rig managers and drillers for awareness of overall component inspections.

- Rig managers and drillers will continue to perform Level II inspections of entire mast structures, paying special attention to the carrier, ears, mast derrick pins and A-frame.

Ask yourself or your crew

- How can something like this happen here (e.g. on our site)?

- What safety measures (i.e. procedures, controls/barriers) do we have in place to mitigate the risk?

- How do we know the risk controls/barriers are working?

- What improvements or changes should we make to the procedures, controls/barriers or the way we work?

The crew was lowering a slant rig mast and heard a ‘pop’. The mast was leaning towards the side of the carrier. A third-party inspection revealed two weld failures at the brackets that pin the mast to the A-frame.

Original material courtesy of Energy Safety Canada

![]()

Other external resources: CAODC Level III Inspection Checklist