-

What happened?

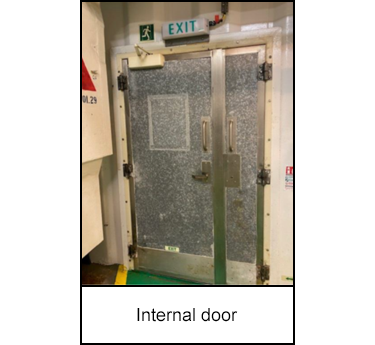

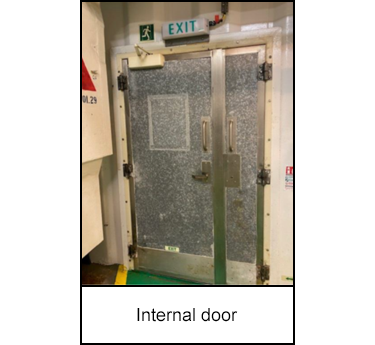

The injured party (IP) was leaving their worksite on the utilities level of the installation and were attempting to open an internal door.

The door was found to be harder to open than normal, so they used their foot as leverage against the wall, but in one motion their foot slipped, and they twisted their shoulder causing sudden pain.

The IP reported to the medic where they received non-prescription pain relief. After consultation with the doctor, the IP was medevac’d on a routine flight to the A&E department of the local hospital.

After the IP completed an MRI scan, it was established that there was some ligament damage between the collar bone and shoulder.

-

Why did it happen?

The investigation has indicated that the heating, ventilation, and air conditioning (HVAC) in the area was not operating, causing a pressure differential, and making the door harder to open than normal.

As a result of the door being harder to open, the IP adopted an improper body position or posture to attempt to ‘lever’ the door open.

This improper position caused the IP to slip and twist, causing the injury to their shoulder.

The potential hazard was not identified as part of HVAC failure risk assessment or management of change (MoC) process and subsequently appropriate mitigations (e.g. identifying alternative routes) were not put in place.

-

What did they learn?

Aim to identify all potential hazards as part of risk assessments and management of change processes and put appropriate mitigations in place.

Always consider your ‘spatial awareness’ when moving around work areas.

Ensure that when completing risk assessments and MoC processes that, as far as is practicable, that all potential introduced hazards are considered.

If you identify potential hazards in the workplace, STOP THE JOB, and report them. Use the 20-second scan before, during and after completing work scopes.

-

Ask yourself or your crew

How can we better detect and report HVAC or environmental system issues before they lead to unsafe conditions?

Are we confident that our current MoC process would catch a similar issue? If not, what’s missing?

Do we have a clear process for reporting minor facility issues (like a stiff door) before they lead to injuries? How well is that process working?

If a similar HVAC failure happened in our area, what alternative routes or workarounds do we have, and are they clearly communicated?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

The injured party (IP) was leaving their worksite on the utilities level of the installation and were attempting to open an internal door.

The door was found to be harder to open than normal, so they used their foot as leverage against the wall, but in one motion their foot slipped, and they twisted their shoulder causing sudden pain.

The IP reported to the medic where they received non-prescription pain relief. After consultation with the doctor, the IP was medevac’d on a routine flight to the A&E department of the local hospital.

After the IP completed an MRI scan, it was established that there was some ligament damage between the collar bone and shoulder.

Why did it happen?

The investigation has indicated that the heating, ventilation, and air conditioning (HVAC) in the area was not operating, causing a pressure differential, and making the door harder to open than normal.

As a result of the door being harder to open, the IP adopted an improper body position or posture to attempt to ‘lever’ the door open.

This improper position caused the IP to slip and twist, causing the injury to their shoulder.

The potential hazard was not identified as part of HVAC failure risk assessment or management of change (MoC) process and subsequently appropriate mitigations (e.g. identifying alternative routes) were not put in place.

What did they learn?

Aim to identify all potential hazards as part of risk assessments and management of change processes and put appropriate mitigations in place.

Always consider your ‘spatial awareness’ when moving around work areas.

Ensure that when completing risk assessments and MoC processes that, as far as is practicable, that all potential introduced hazards are considered.

If you identify potential hazards in the workplace, STOP THE JOB, and report them. Use the 20-second scan before, during and after completing work scopes.

Ask yourself or your crew

How can we better detect and report HVAC or environmental system issues before they lead to unsafe conditions?

Are we confident that our current MoC process would catch a similar issue? If not, what’s missing?

Do we have a clear process for reporting minor facility issues (like a stiff door) before they lead to injuries? How well is that process working?

If a similar HVAC failure happened in our area, what alternative routes or workarounds do we have, and are they clearly communicated?

While attempting to open a stiff internal door, an employee slipped and twisted their shoulder, later found to have ligament damage, due to a pressure differential caused by a HVAC failure.