-

What happened?

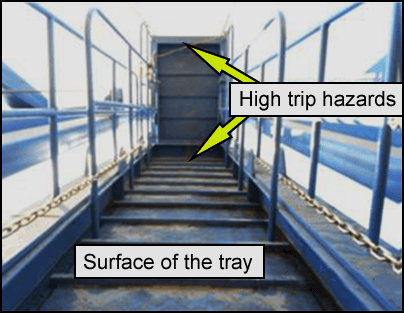

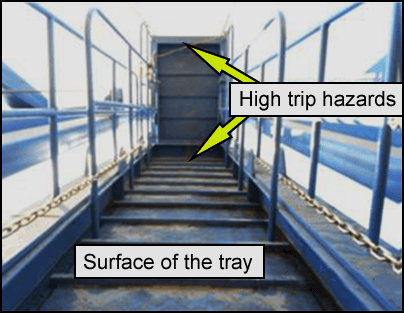

A gangway had been newly installed, and the first transfer test was performed.

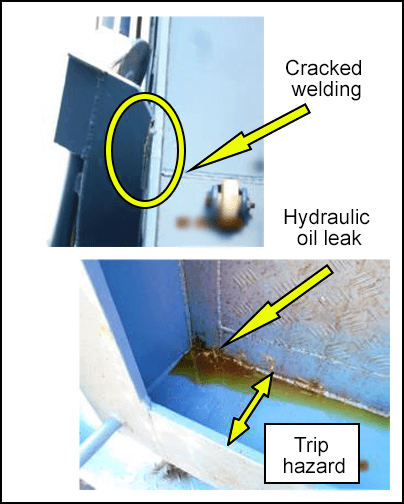

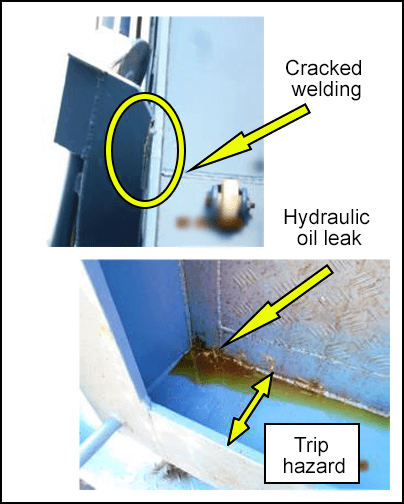

The captain observed several unsafe conditions – a trip hazard and a minor hydraulic leak.

He immediately exercised the ‘stop work authority’.

On further inspection of the gangway, cracks were found on the welding seams.

The gangway was quarantined until the corrective actions could be implemented.

-

Why did it happen?

The crew thoroughly inspected the gangway before use.

The captain implemented the ‘stop work authority’ when the gangway was found to be unsafe.

The gangway was quarantined until necessary repairs were completed and it was safe to use.

-

What did they learn?

Remind crew that they are authorised and expected to exercise the stop work policy if they are in doubt about any aspect of safety.

Conduct a pre-job/installation inspection of all equipment to ensure that it is fit for purpose and safe to use.

Any equipment found to be unsafe should be quarantined.

-

Ask yourself or your crew

Have you ever issued a stop work authority?

- What for?

- Were you worried about issuing it?

- How was it received?

What should you check for when inspecting new equipment? Do you perform the same checks on older equipment?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A gangway had been newly installed, and the first transfer test was performed.

The captain observed several unsafe conditions – a trip hazard and a minor hydraulic leak.

He immediately exercised the ‘stop work authority’.

On further inspection of the gangway, cracks were found on the welding seams.

The gangway was quarantined until the corrective actions could be implemented.

Why did it happen?

The crew thoroughly inspected the gangway before use.

The captain implemented the ‘stop work authority’ when the gangway was found to be unsafe.

The gangway was quarantined until necessary repairs were completed and it was safe to use.

What did they learn?

Remind crew that they are authorised and expected to exercise the stop work policy if they are in doubt about any aspect of safety.

Conduct a pre-job/installation inspection of all equipment to ensure that it is fit for purpose and safe to use.

Any equipment found to be unsafe should be quarantined.

Ask yourself or your crew

Have you ever issued a stop work authority?

- What for?

- Were you worried about issuing it?

- How was it received?

What should you check for when inspecting new equipment? Do you perform the same checks on older equipment?

A gangway had been newly installed and the first transfer test was performed. The captain observed several unsafe conditions and issued a stop work authority. The gangway was quarantined until it could be repaired.