-

What happened?

A rig crew was attempting to manually latch a running tool onto the top of a tubing liner pump downhole.

A rod wheel was installed onto the rod string.

Workers on the rig floor held 10 to 15 turns of torque into the rod string with the wheel as the rod string was lifted.

The running tool detached from the lock assembly causing the workers to lose their grip on the rod wheel.

The release of torque caused the rod wheel to backspin uncontrolled.

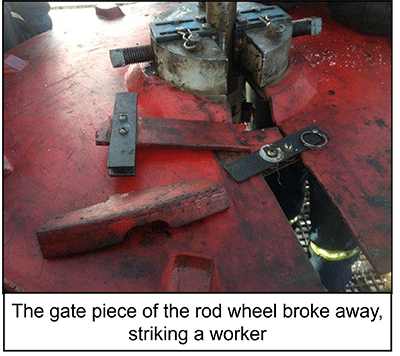

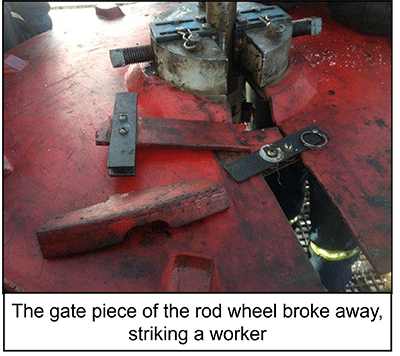

While spinning, the gate piece of the rod wheel broke away from the main body of the wheel, striking a worker in the face and resulting in major facial injuries.

-

Why did it happen?

Defective tools:

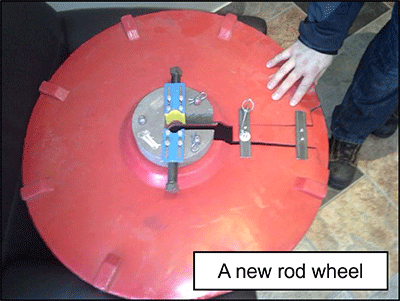

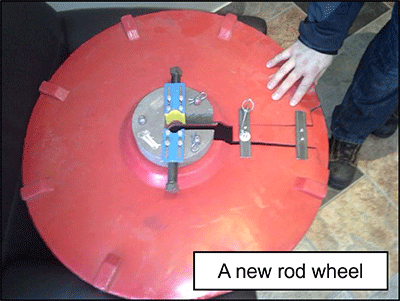

- The rod wheel is made of plastic and if the rod wheel backspins from torque, the gate in the wheel is subject to failure.

Improper procedures:

- There is no safe method of placing torque into a rod string using a rod wheel. If control of the wheel is lost, the resulting backspin places workers at risk from disintegration of the gate.

-

What did they learn?

Investigation provided the following learnings/recommendations:

- There are no manufacturer operating specifications for the rod wheel to identify torque limitations or maximum number of turns on a rod string before it becomes a hazard.

- Use of a rod wheel relies on workers manually holding a device with torque applied and, if they lose control of the wheel and it fails, there is no way to protect the workers.

- Recommended engineering control: The use of jaw-type rod tong dies coupled with a backup arm to rotate the rod string removes the hazard to workers.

-

Ask yourself or your crew

- How can something like this happen here (e.g. on our site)?

- What safety measures (i.e. procedures, controls/barriers) do we have in place to mitigate the risk?

- How do we know the risk controls/barriers are working?

- What improvements or changes should we make to the procedures, controls/barriers or the way we work?

Add to homescreen

If you want to add this app to home screen tap and then ‘Add to Home Screen’.

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A rig crew was attempting to manually latch a running tool onto the top of a tubing liner pump downhole.

A rod wheel was installed onto the rod string.

Workers on the rig floor held 10 to 15 turns of torque into the rod string with the wheel as the rod string was lifted.

The running tool detached from the lock assembly causing the workers to lose their grip on the rod wheel.

The release of torque caused the rod wheel to backspin uncontrolled.

While spinning, the gate piece of the rod wheel broke away from the main body of the wheel, striking a worker in the face and resulting in major facial injuries.

Why did it happen?

Defective tools:

- The rod wheel is made of plastic and if the rod wheel backspins from torque, the gate in the wheel is subject to failure.

Improper procedures:

- There is no safe method of placing torque into a rod string using a rod wheel. If control of the wheel is lost, the resulting backspin places workers at risk from disintegration of the gate.

What did they learn?

Investigation provided the following learnings/recommendations:

- There are no manufacturer operating specifications for the rod wheel to identify torque limitations or maximum number of turns on a rod string before it becomes a hazard.

- Use of a rod wheel relies on workers manually holding a device with torque applied and, if they lose control of the wheel and it fails, there is no way to protect the workers.

- Recommended engineering control: The use of jaw-type rod tong dies coupled with a backup arm to rotate the rod string removes the hazard to workers.

Ask yourself or your crew

- How can something like this happen here (e.g. on our site)?

- What safety measures (i.e. procedures, controls/barriers) do we have in place to mitigate the risk?

- How do we know the risk controls/barriers are working?

- What improvements or changes should we make to the procedures, controls/barriers or the way we work?

Published on 22/04/24

933 Views

A rig crew was attempting to manually latch a running tool onto the tip of a tubing liner pump downhole. A rod wheel was installed onto the rod string. Workers on the rig floor held turns of torque into the rod string with the wheel as the rod string was lifted. The workers lost their grip on the rod wheel. The release of torque caused the rod wheel to backspin uncontrolled. While spinning, the gate piece of the rod wheel broke away from the main body of the wheel, striking a worker in the face resulting in major facial injuries.

Original material courtesy of Energy Safety Canada