-

What happened?

A rig crew was pulling a 1 ¼” (32mm) rod string out of a well.

As one of the rods was being laid out in the trough, it detached from the rod elevator and fell 1.5 metres (4.9 feet) into the trough.

The rod eventually came to rest with one end on the ground and the other end on the handrail of the workfloor.

All personnel were standing clear of the potential line of fire. No injuries were sustained.

-

Why did it happen?

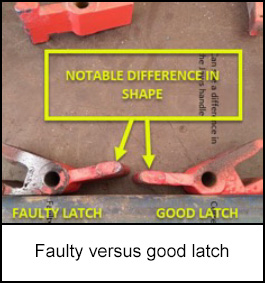

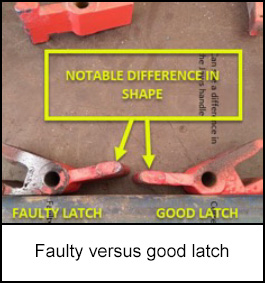

The shape of the 1 ¼” (32mm) front latches installed by the original equipment manufacturer (OEM) were different to other 1 ¼” (32mm) latches from the same OEM with identical part number and size marking.

The variation in shape increased the gap between the front latches when closed.

This resulted in the rod being able to force open the latch without the latch lever being operated.

The rod elevators could be released from a rod (pulled off by hand) without operating the latch release levers. When the rod was suspended, the latches allowed the rod to drop.

The rod elevator assembly was inspected prior to use. However, as the rod elevator was new, it had only previously been used on one well and the latches had been installed by the OEM, the increased gap between front latches was not flagged as a concern during inspection.

-

What did they learn?

Ensure rod elevator checks include assessing the gap between front latches. Highlight, communicate and emphasise what is/is not acceptable.

Inspect rod elevators for a similar defect. Remove or replace defective equipment or parts.

Ensure standard work procedures for tripping rods include set-up and demarcation of exclusion zones around the rod trough. Require rig crew working on the rig floor to stand clear as equipment (e.g. rods) are lowered or raised.

-

Ask yourself or your crew

How often do you check your rod elevators? What is your inspection criteria? Where is this captured? How detailed is it?

Are you aware that rods may be released from rod elevators during tripping operations?

What key controls do you have in place to remove yourself and your team members from the potential line of fire when tripping rods?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A rig crew was pulling a 1 ¼” (32mm) rod string out of a well.

As one of the rods was being laid out in the trough, it detached from the rod elevator and fell 1.5 metres (4.9 feet) into the trough.

The rod eventually came to rest with one end on the ground and the other end on the handrail of the workfloor.

All personnel were standing clear of the potential line of fire. No injuries were sustained.

Why did it happen?

The shape of the 1 ¼” (32mm) front latches installed by the original equipment manufacturer (OEM) were different to other 1 ¼” (32mm) latches from the same OEM with identical part number and size marking.

The variation in shape increased the gap between the front latches when closed.

This resulted in the rod being able to force open the latch without the latch lever being operated.

The rod elevators could be released from a rod (pulled off by hand) without operating the latch release levers. When the rod was suspended, the latches allowed the rod to drop.

The rod elevator assembly was inspected prior to use. However, as the rod elevator was new, it had only previously been used on one well and the latches had been installed by the OEM, the increased gap between front latches was not flagged as a concern during inspection.

What did they learn?

Ensure rod elevator checks include assessing the gap between front latches. Highlight, communicate and emphasise what is/is not acceptable.

Inspect rod elevators for a similar defect. Remove or replace defective equipment or parts.

Ensure standard work procedures for tripping rods include set-up and demarcation of exclusion zones around the rod trough. Require rig crew working on the rig floor to stand clear as equipment (e.g. rods) are lowered or raised.

Ask yourself or your crew

How often do you check your rod elevators? What is your inspection criteria? Where is this captured? How detailed is it?

Are you aware that rods may be released from rod elevators during tripping operations?

What key controls do you have in place to remove yourself and your team members from the potential line of fire when tripping rods?

During a well operation, a rod detached from the rod elevator and fell 1.5 metres (4.9 feet) into the trough due to a design flaw in the latches. Fortunately, no injuries occurred as all personnel were clear of the potential line of fire.

Original material courtesy of Safer Together (Australia)

To access the PDF and PowerPoint versions, please visit https://www.safertogether.com.au/resources/sharing-library/working-with-suspended-load-learning-event-bulletin