-

What happened?

This Safety Alert was initiated by a producer after several incidents were reported relating to loading and unloading heated production fluids.

Workers performing these activities are at risk of chemical exposure and burns when the fluids are heated.

In one incident, a worker suffered a burn injury after coming into direct contact with heated production fluids.

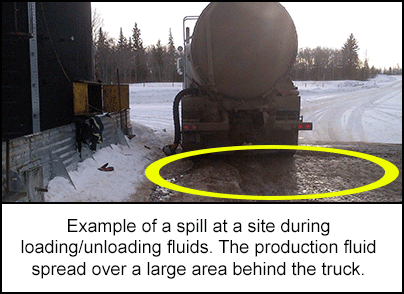

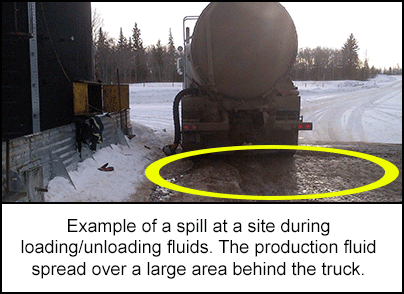

There is also potential for spills and sprays which require clean up and reporting.

-

Why did it happen?

This type of incident occurs when the truck load line is disconnected before the production valve is closed and residual pressure remains in the line. As a result, when the line is disconnected, fluid escapes and can come into direct contact with the worker and the environment.

Contributing factors:

- Residual pressure in the load line was not released.

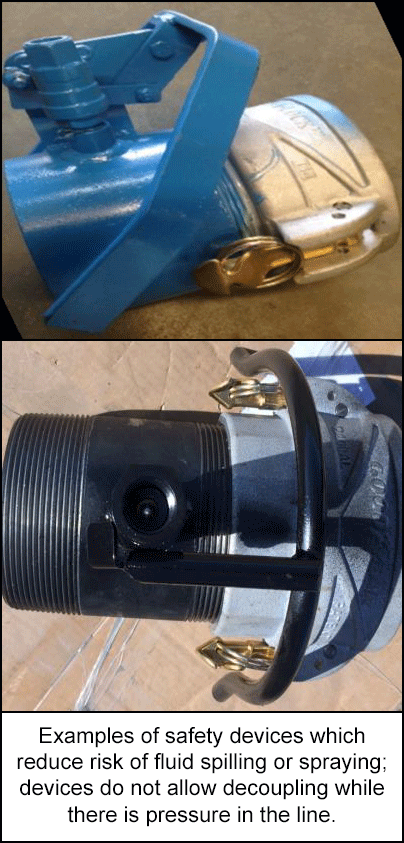

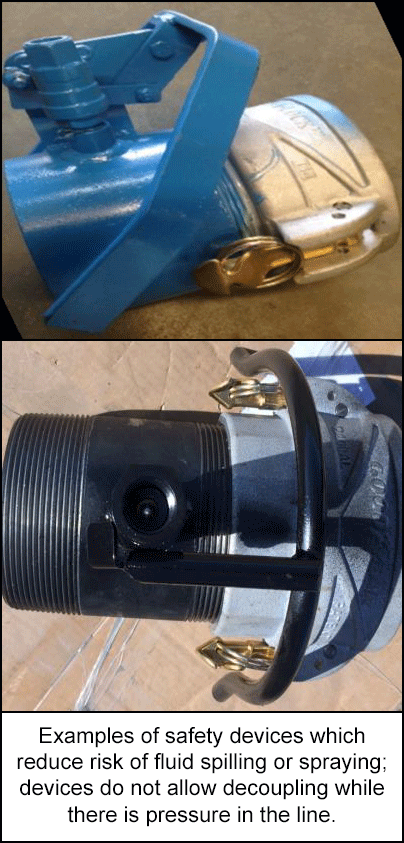

- A safety device (pictured below) was not used.

- Unaware of physical characteristics of fluids being handled/hauled.

- Complacency because it is a routine task.

-

What did they learn?

- Fluid hauling companies should consider requiring company-wide use of a safety device, like the ones in the photos below, which are specially-designed to protect workers and reduce risk of spills.

- Workers must wear personal protective equipment (PPE) appropriate for the product being loaded and unloaded, e.g. face shield and not just goggles.

- Operating companies should ensure fluid hauling companies have written loading/unloading procedures and trained workers.

- Operating companies must communicate the following site specific information:

- Load line hazards, including heat, pressure and contents

- Copies of Safety Data Sheets (SDS) for fluids

- Site specific contacts and emergency procedure

-

Ask yourself or your crew

- How can something like this happen here (e.g. on our site)?

- What safety measures (i.e. procedures, controls/barriers) do we have in place to mitigate the risk?

- How do we know the risk controls/barriers are working?

- What improvements or changes should we make to the procedures, controls/barriers or the way we work?

Add to homescreen

If you want to add this app to home screen tap and then ‘Add to Home Screen’.

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

This Safety Alert was initiated by a producer after several incidents were reported relating to loading and unloading heated production fluids.

Workers performing these activities are at risk of chemical exposure and burns when the fluids are heated.

In one incident, a worker suffered a burn injury after coming into direct contact with heated production fluids.

There is also potential for spills and sprays which require clean up and reporting.

Why did it happen?

This type of incident occurs when the truck load line is disconnected before the production valve is closed and residual pressure remains in the line. As a result, when the line is disconnected, fluid escapes and can come into direct contact with the worker and the environment.

Contributing factors:

- Residual pressure in the load line was not released.

- A safety device (pictured below) was not used.

- Unaware of physical characteristics of fluids being handled/hauled.

- Complacency because it is a routine task.

What did they learn?

- Fluid hauling companies should consider requiring company-wide use of a safety device, like the ones in the photos below, which are specially-designed to protect workers and reduce risk of spills.

- Workers must wear personal protective equipment (PPE) appropriate for the product being loaded and unloaded, e.g. face shield and not just goggles.

- Operating companies should ensure fluid hauling companies have written loading/unloading procedures and trained workers.

- Operating companies must communicate the following site specific information:

- Load line hazards, including heat, pressure and contents

- Copies of Safety Data Sheets (SDS) for fluids

- Site specific contacts and emergency procedure

Ask yourself or your crew

- How can something like this happen here (e.g. on our site)?

- What safety measures (i.e. procedures, controls/barriers) do we have in place to mitigate the risk?

- How do we know the risk controls/barriers are working?

- What improvements or changes should we make to the procedures, controls/barriers or the way we work?

Published on 10/06/23

1561 Views

Workers performing loading and unloading of production fluids are at risk of chemical exposure and burns when the fluids are heated. In one incident, a worker suffered a burn injury after coming into direct contact with heated production fluids. There is also potential for spills and sprays which require clean up and reporting.