-

What happened?

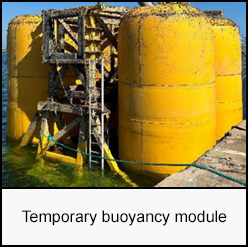

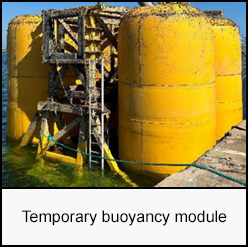

During the removal of a Temporary buoyancy module (TBM) from a Floating offshore wind turbine (FOWT), the TBM unexpectedly rolled while moored at the quay.

Two riggers were on the TBM deck during the instability; one jumped into the water, and the other fell between the quay fender and TBM.

The second rigger was compressed underwater between the TBM and fender but was wearing an activated lifejacket.

Two coworkers jumped in and successfully rescued both riggers.

One rigger was unharmed but in shock; the other received on-site first aid and was airlifted to hospital.

-

Why did it happen?

The TBM was inflated to 1.4 psi instead of the 6 psi required for towing, this decreased stability and increased rollover risk.

The task plan lacked operational pressure limits and did not warn about minimum pressure or stability risks.

Personnel were not removed from the TBM during movement, despite the capsize hazard.

HSE and Rigging teams were not involved in Job safety analysis (JSA).

A Management of change removed the use of a crane without proper risk acknowledgement or mitigation.

The crane, used in the previous removal for stability, was not used during this incident.

-

What did they learn?

TBM movements must be performed without personnel onboard to prevent injury during instability.

TBM should be inflated to 6 psi before towing or movement to ensure structural stability.

Contingency cranes should remain connected throughout the operation to control unexpected shifts.

All operational plans must involve HSE and technical teams for proper risk identification.

MoCs must assess and mitigate new risks when control measures are removed or altered.

Work must be stopped if any unexpected or unsafe condition is observed, and risks must be reassessed

-

Ask yourself or your crew

Are all pressure and stability requirements clearly defined and followed during similar operations?

How do we ensure people are not exposed to unnecessary risks during equipment movements?

Are HSE, rigging, and engineering teams consistently involved in planning and risk assessments?

How do we fully assess and mitigate risks when modifying task plans or removing safety controls?

Would we be able recognise and act on signs of instability or unexpected behaviour during a task?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

During the removal of a Temporary buoyancy module (TBM) from a Floating offshore wind turbine (FOWT), the TBM unexpectedly rolled while moored at the quay.

Two riggers were on the TBM deck during the instability; one jumped into the water, and the other fell between the quay fender and TBM.

The second rigger was compressed underwater between the TBM and fender but was wearing an activated lifejacket.

Two coworkers jumped in and successfully rescued both riggers.

One rigger was unharmed but in shock; the other received on-site first aid and was airlifted to hospital.

Why did it happen?

The TBM was inflated to 1.4 psi instead of the 6 psi required for towing, this decreased stability and increased rollover risk.

The task plan lacked operational pressure limits and did not warn about minimum pressure or stability risks.

Personnel were not removed from the TBM during movement, despite the capsize hazard.

HSE and Rigging teams were not involved in Job safety analysis (JSA).

A Management of change removed the use of a crane without proper risk acknowledgement or mitigation.

The crane, used in the previous removal for stability, was not used during this incident.

What did they learn?

TBM movements must be performed without personnel onboard to prevent injury during instability.

TBM should be inflated to 6 psi before towing or movement to ensure structural stability.

Contingency cranes should remain connected throughout the operation to control unexpected shifts.

All operational plans must involve HSE and technical teams for proper risk identification.

MoCs must assess and mitigate new risks when control measures are removed or altered.

Work must be stopped if any unexpected or unsafe condition is observed, and risks must be reassessed

Ask yourself or your crew

Are all pressure and stability requirements clearly defined and followed during similar operations?

How do we ensure people are not exposed to unnecessary risks during equipment movements?

Are HSE, rigging, and engineering teams consistently involved in planning and risk assessments?

How do we fully assess and mitigate risks when modifying task plans or removing safety controls?

Would we be able recognise and act on signs of instability or unexpected behaviour during a task?

Temporary buoyancy module rolled at quay during removal; 2 riggers fell and 1 trapped underwater. Both rescued; 1 airlifted, 1 in shock but unharmed.