-

What happened?

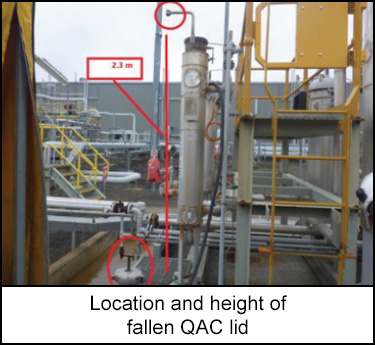

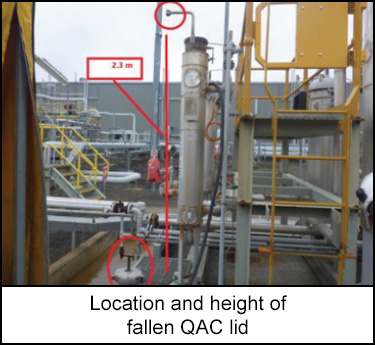

A quick actuating closure (QAC) lid weighing 16kg (35lbs) fell to a skid platform below from a height of 2.3 metres (7 feet 7 inches).

The lid is part of a triethylene glycol (TEG) particulate filter and was open to allow for a filter change.

An operator was working in a bunded area in close proximity to the drop zone, with no barricading (not on the skid itself, under the load) while waiting for the vessel to drain.

A combination of the component mass and height of the drop had the potential to cause a fatality.

-

Why did it happen?

The lid of the closure is threaded to allow easy opening. This is connected to a davit arm via a threaded spindle which has a mechanical stop washer to prevent the lid from falling from the davit.

The QAC lid unwound off the threaded spindle under its own weight.

The mechanical stop washer failed, allowing the lid to fall, because it was subject to a load that it was not designed for.

The hazard of a suspended object was not recognised.

-

What did they learn?

Inspections of the filter vessels do not typically capture the condition of the davit arm and mechanical stop washer.

Wear and tear on aged equipment can compromise its integrity, which places onus on having the correct inspection and maintenance regime to ensure its ongoing fitness for service.

The capability guide for this task does not highlight the hazard of working under a suspended object, or dropped tools. Therefore these hazards were not recognised and the appropriate controls (engineering and procedural) were not maintained or implemented. Since the incident a method to stop the lid rotating (chain / wire) has been developed, which adds another layer of control.

The hazard of a suspended object that only presents itself during inspection and maintenance activities is not always obvious during normal operations.

A personal task assessment or other type of risk assessment is not typically completed for this activity. It is a routine activity that is done multiple times a swing.

Hazards from operation and maintenance practices can become normalised (habituated) over time with repetition (e.g. use of a mallet to close a QAC lid; potential for suspended objects when performing a task). This makes it less likely that these hazards will be recognised over time.

A hammer is used to open and close the QAC lid. This is against the original equipment manufacturer (OEM) recommendations, but the recommended OEM practice is not practical in this application.

The OEM recommends inspection of the closure threads. This inspection and findings are not well documented.

OEM recommendations must be considered for the installation and operation of equipment.

-

Ask yourself or your crew

Do you have equipment with QAC lids at your workplace? What engineering controls do you have in place to prevent the lid from rotating free from the davit?

Do you know and follow the correct procedures for opening and closing QAC lids?

When did you last conduct an inspection of the lid assemblies to assess the condition of the stop washers?

Does your inspection and maintenance regime adequately address wear and tear on aged equipment and ensure its ongoing fitness for service?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A quick actuating closure (QAC) lid weighing 16kg (35lbs) fell to a skid platform below from a height of 2.3 metres (7 feet 7 inches).

The lid is part of a triethylene glycol (TEG) particulate filter and was open to allow for a filter change.

An operator was working in a bunded area in close proximity to the drop zone, with no barricading (not on the skid itself, under the load) while waiting for the vessel to drain.

A combination of the component mass and height of the drop had the potential to cause a fatality.

Why did it happen?

The lid of the closure is threaded to allow easy opening. This is connected to a davit arm via a threaded spindle which has a mechanical stop washer to prevent the lid from falling from the davit.

The QAC lid unwound off the threaded spindle under its own weight.

The mechanical stop washer failed, allowing the lid to fall, because it was subject to a load that it was not designed for.

The hazard of a suspended object was not recognised.

What did they learn?

Inspections of the filter vessels do not typically capture the condition of the davit arm and mechanical stop washer.

Wear and tear on aged equipment can compromise its integrity, which places onus on having the correct inspection and maintenance regime to ensure its ongoing fitness for service.

The capability guide for this task does not highlight the hazard of working under a suspended object, or dropped tools. Therefore these hazards were not recognised and the appropriate controls (engineering and procedural) were not maintained or implemented. Since the incident a method to stop the lid rotating (chain / wire) has been developed, which adds another layer of control.

The hazard of a suspended object that only presents itself during inspection and maintenance activities is not always obvious during normal operations.

A personal task assessment or other type of risk assessment is not typically completed for this activity. It is a routine activity that is done multiple times a swing.

Hazards from operation and maintenance practices can become normalised (habituated) over time with repetition (e.g. use of a mallet to close a QAC lid; potential for suspended objects when performing a task). This makes it less likely that these hazards will be recognised over time.

A hammer is used to open and close the QAC lid. This is against the original equipment manufacturer (OEM) recommendations, but the recommended OEM practice is not practical in this application.

The OEM recommends inspection of the closure threads. This inspection and findings are not well documented.

OEM recommendations must be considered for the installation and operation of equipment.

Ask yourself or your crew

Do you have equipment with QAC lids at your workplace? What engineering controls do you have in place to prevent the lid from rotating free from the davit?

Do you know and follow the correct procedures for opening and closing QAC lids?

When did you last conduct an inspection of the lid assemblies to assess the condition of the stop washers?

Does your inspection and maintenance regime adequately address wear and tear on aged equipment and ensure its ongoing fitness for service?

A 16kg (35lbs) quick actuating closure (QAC) lid fell from a height of 2.3 meters (7 feet 7 inches) during a filter change, posing a fatal risk to an operator working nearby without barricades.

Original material courtesy of Safer Together (Australia)

To access the PDF and PowerPoint versions, please visit https://www.safertogether.com.au/resources/sharing-library/maintaining-process-equipment-dropped-object-leb-toolbox