-

What happened?

The organisation was working on a pipeline replacement project in an inland waterway. They were preparing to lower the pipeline.

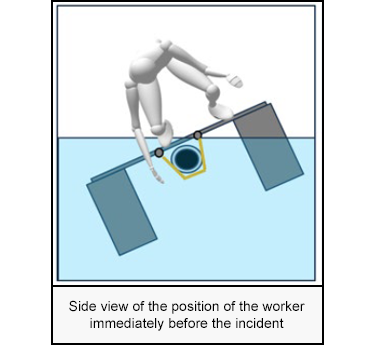

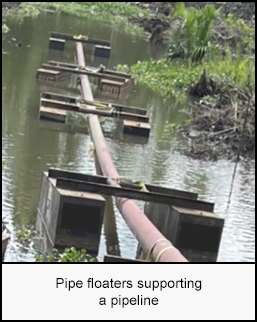

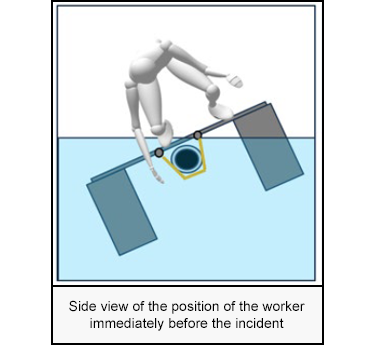

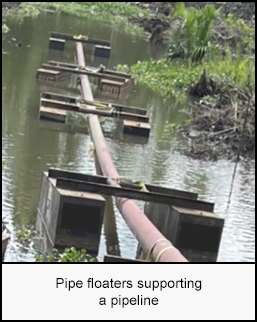

A worker in a remote location boarded a tilting pipe floater to access the rachet strap to release the pipe floater from the pipeline.

After unsuccessful attempts to use the rachet handle, the worker reached into the water and tried to cut the strap with a knife from a point that placed his arm in the line of fire between the 8 inch (20cm) pipeline release and one of the pontoons of the pipe floater.

Once his arm became trapped, the weight of the pipeline and the orientation of the floater dragged him underwater. The worker was wearing a personal floatation device at the time of the incident.

The worker was recovered from the water, CPR was administered, and he was later pronounced dead.

-

What did they learn?

Routine tasks are not without risks. Abnormal conditions may not be identified without sufficient breakdown of each step and proper risk assessment.

When working over water, personnel should stay within the confines of an approved vessel or platform; any deviation should be properly risk-assessed and approved.

Multiple contractors executing similar scope of work with different methods can introduce opportunity to benchmark, learn, and improve.

Assure the availability and use of tools or other mitigations to eliminate placing body or limbs in the line of fire.

Establish guardrails for site improvisation outside of project execution planning.

Evaluate the adequacy of onsite resources and oversight at work locations, including personnel, equipment, and emergency response.

-

Safeguards to consider for work over water:

Consider whether the following can be applied to reduce the risk of working over water:

- Remote or alternative means for performing a task over water.

- Training to improve ability to recognise abnormal or unsafe conditions where Stop Work should be used.

- Clear requirements or conditions for safe work progression.

- A change management process to control site improvisation during work execution.

- Appropriate tools or other mitigations to avoid putting bodies in the line of fire.

- Availability of adequate emergency response resources.

- Engineering design that eliminates pinch points.

-

Ask yourself or your crew

Have we assessed the risks for tasks associated with working over water? What are they?

What are the additional risks associated with working in a remote location?

Have we evaluated the adequacy of our resources at remote work locations, including work oversight?

What are the barriers to assuring safe execution when working in a remote location?

Did we confirm the design specification/certification of equipment to execute work at the site? How assured are we in our ability to respond effectively to an emergency?

How effectively have we evaluated and mitigated potential hazards associated with each step in a ‘routine’ task?

How can we reduce or eliminate the human interface in tasks with potential pinch points/ getting caught underwater?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

The organisation was working on a pipeline replacement project in an inland waterway. They were preparing to lower the pipeline.

A worker in a remote location boarded a tilting pipe floater to access the rachet strap to release the pipe floater from the pipeline.

After unsuccessful attempts to use the rachet handle, the worker reached into the water and tried to cut the strap with a knife from a point that placed his arm in the line of fire between the 8 inch (20cm) pipeline release and one of the pontoons of the pipe floater.

Once his arm became trapped, the weight of the pipeline and the orientation of the floater dragged him underwater. The worker was wearing a personal floatation device at the time of the incident.

The worker was recovered from the water, CPR was administered, and he was later pronounced dead.

What did they learn?

Routine tasks are not without risks. Abnormal conditions may not be identified without sufficient breakdown of each step and proper risk assessment.

When working over water, personnel should stay within the confines of an approved vessel or platform; any deviation should be properly risk-assessed and approved.

Multiple contractors executing similar scope of work with different methods can introduce opportunity to benchmark, learn, and improve.

Assure the availability and use of tools or other mitigations to eliminate placing body or limbs in the line of fire.

Establish guardrails for site improvisation outside of project execution planning.

Evaluate the adequacy of onsite resources and oversight at work locations, including personnel, equipment, and emergency response.

Safeguards to consider for work over water:

Consider whether the following can be applied to reduce the risk of working over water:

- Remote or alternative means for performing a task over water.

- Training to improve ability to recognise abnormal or unsafe conditions where Stop Work should be used.

- Clear requirements or conditions for safe work progression.

- A change management process to control site improvisation during work execution.

- Appropriate tools or other mitigations to avoid putting bodies in the line of fire.

- Availability of adequate emergency response resources.

- Engineering design that eliminates pinch points.

Ask yourself or your crew

Have we assessed the risks for tasks associated with working over water? What are they?

What are the additional risks associated with working in a remote location?

Have we evaluated the adequacy of our resources at remote work locations, including work oversight?

What are the barriers to assuring safe execution when working in a remote location?

Did we confirm the design specification/certification of equipment to execute work at the site? How assured are we in our ability to respond effectively to an emergency?

How effectively have we evaluated and mitigated potential hazards associated with each step in a ‘routine’ task?

How can we reduce or eliminate the human interface in tasks with potential pinch points/ getting caught underwater?

A worker in a remote location boarded a tilting pipe floater to access the rachet strap to release the pipe floater from the pipeline. His arm became trapped, the weight of the pipeline and the orientation of the floater dragged him underwater.