-

What happened?

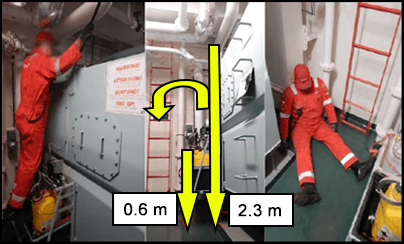

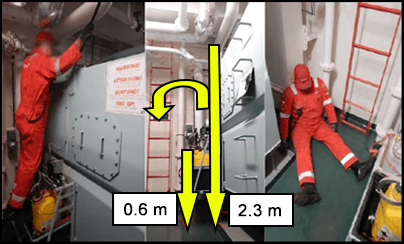

A sewage tank inspection hatch on a vessel had to be opened to check the condition of a faulty sensor.

The inspecting crew member was standing on a fixed rack to gain access.

He was overcome by a H2S plume from the tank.

The crew member fell onto the deck and was unconscious for 90 seconds. Luckily only minor cuts and bruises were experienced.

-

Why did it happen?

Sewage treatment plant had not been operated and maintained in line with manufacturer’s instructions, leading to build-up of H2S.

The manufacturer’s instructions for opening the inspection tank were not followed.

Safe systems of work were not followed.

Risk assessments and permit to work procedures were not adhered to. Potential for hazardous gases was not identified as part of the risk assessment.

Inadequate working at height controls.

Inadequate tool box talks held.

-

What did they learn?

Follow safe systems of work and procedures for all maintenance activities. Adhere to permit to work, task risk assessment, toolbox talks, working at height and associated procedures.

Ensure that all relevant personnel are familiar with the maintenance operation, required maintenance activities, associated risks and required safety controls as defined by the manufacturer’s instructions.

Ensure staff are aware of risks associated with H2S and control measures are implemented, including breathing apparatus if there is potential for H2S release.

Stop the job if new risks emerge or you feel unsafe or uncomfortable.

-

Ask yourself or your crew

How can something like this happen here?

Have we identified a risk of H2S on today’s job?

How comfortable do you feel when working around H2S?

What controls do we have in place to prevent this?

How can we improve these controls?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A sewage tank inspection hatch on a vessel had to be opened to check the condition of a faulty sensor.

The inspecting crew member was standing on a fixed rack to gain access.

He was overcome by a H2S plume from the tank.

The crew member fell onto the deck and was unconscious for 90 seconds. Luckily only minor cuts and bruises were experienced.

Why did it happen?

Sewage treatment plant had not been operated and maintained in line with manufacturer’s instructions, leading to build-up of H2S.

The manufacturer’s instructions for opening the inspection tank were not followed.

Safe systems of work were not followed.

Risk assessments and permit to work procedures were not adhered to. Potential for hazardous gases was not identified as part of the risk assessment.

Inadequate working at height controls.

Inadequate tool box talks held.

What did they learn?

Follow safe systems of work and procedures for all maintenance activities. Adhere to permit to work, task risk assessment, toolbox talks, working at height and associated procedures.

Ensure that all relevant personnel are familiar with the maintenance operation, required maintenance activities, associated risks and required safety controls as defined by the manufacturer’s instructions.

Ensure staff are aware of risks associated with H2S and control measures are implemented, including breathing apparatus if there is potential for H2S release.

Stop the job if new risks emerge or you feel unsafe or uncomfortable.

Ask yourself or your crew

How can something like this happen here?

Have we identified a risk of H2S on today’s job?

How comfortable do you feel when working around H2S?

What controls do we have in place to prevent this?

How can we improve these controls?

A sewage tank inspection hatch on a vessel had to be opened to check the condition of a faulty sensor. The inspecting crew member was overcome by a H2S plume from the tank.