-

What happened?

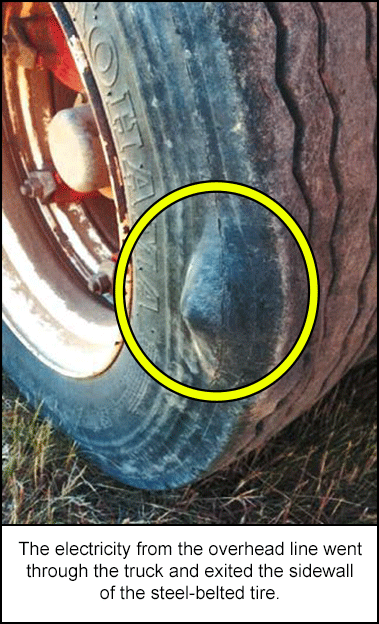

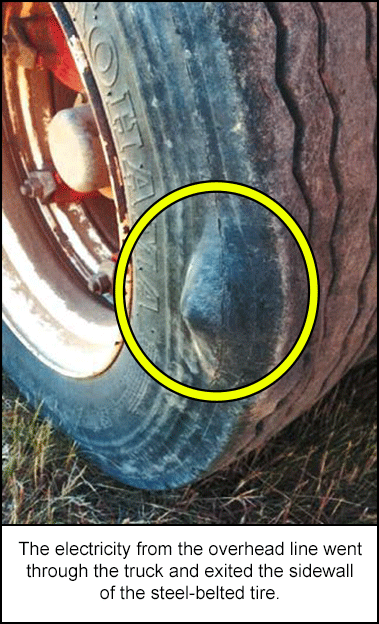

Electricity from a 15,000-volt overhead powerline damaged a mud tank and trailer as they were being transported.

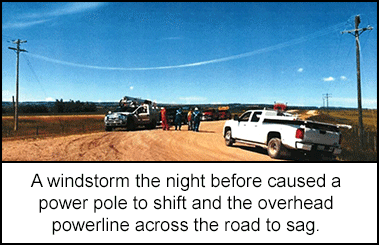

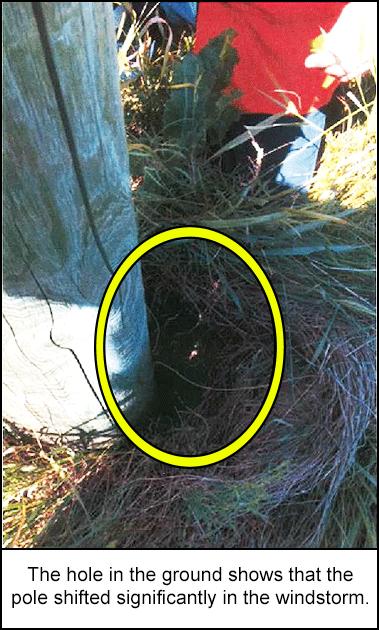

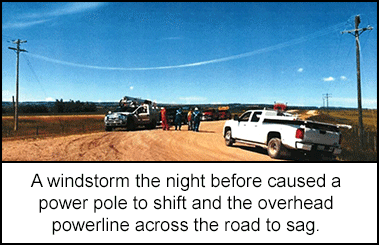

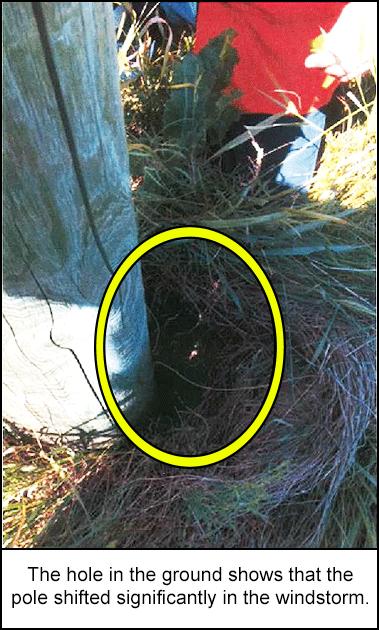

The line and load were measured four days prior and deemed within the safe distance as per provincial OH&S regulations. However, a wind storm occurred the night before the tank move and the power pole had shifted, causing the line to sag. When the truck drove underneath, the overhead powerline arced on the roof of the mud tank.

The tank and trailer sustained extensive damage, and while the driver remained safe, this had the potential to be a very serious incident.

-

Why did it happen?

A violent wind storm moved the power pole, causing the line to sag more than 0.7m so that it was no longer a safe distance from the load being transported. In addition, the pole’s anchor line was at a 90 degree angle, so the pole was not properly supported.

Contributing factors:

- Line height was not measured immediately prior to transporting the load.

- No spotter was used.

-

What did they learn?

- Include conducting a hazard assessment of travel route prior to transportation of equipment.

- Mark and measure all power lines prior to equipment movement.

- Ensure the document containing line measurements and locations is on site and that those measurements are communicated to all personnel.

- Pre-travel the route to ensure all appropriate signage is in place.

- Re-measure height of line immediately prior to moving equipment.

- Use a spotter equipped with two-way communications.

- Be aware of provincial guidelines on overhead powerlines, and safe distances.

- Contact the Owner for any overhead line concerns, including reporting of incidents.

-

Ask yourself or your crew

- How can something like this happen here (e.g. on our site)?

- What safety measures (i.e. procedures, controls/barriers) do we have in place to mitigate the risk?

- How do we know the risk controls/barriers are working?

- What improvements or changes should we make to the procedures, controls/barriers or the way we work?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

Electricity from a 15,000-volt overhead powerline damaged a mud tank and trailer as they were being transported.

The line and load were measured four days prior and deemed within the safe distance as per provincial OH&S regulations. However, a wind storm occurred the night before the tank move and the power pole had shifted, causing the line to sag. When the truck drove underneath, the overhead powerline arced on the roof of the mud tank.

The tank and trailer sustained extensive damage, and while the driver remained safe, this had the potential to be a very serious incident.

Why did it happen?

A violent wind storm moved the power pole, causing the line to sag more than 0.7m so that it was no longer a safe distance from the load being transported. In addition, the pole’s anchor line was at a 90 degree angle, so the pole was not properly supported.

Contributing factors:

- Line height was not measured immediately prior to transporting the load.

- No spotter was used.

What did they learn?

- Include conducting a hazard assessment of travel route prior to transportation of equipment.

- Mark and measure all power lines prior to equipment movement.

- Ensure the document containing line measurements and locations is on site and that those measurements are communicated to all personnel.

- Pre-travel the route to ensure all appropriate signage is in place.

- Re-measure height of line immediately prior to moving equipment.

- Use a spotter equipped with two-way communications.

- Be aware of provincial guidelines on overhead powerlines, and safe distances.

- Contact the Owner for any overhead line concerns, including reporting of incidents.

Ask yourself or your crew

- How can something like this happen here (e.g. on our site)?

- What safety measures (i.e. procedures, controls/barriers) do we have in place to mitigate the risk?

- How do we know the risk controls/barriers are working?

- What improvements or changes should we make to the procedures, controls/barriers or the way we work?

Electricity from an overhead powerline damaged a mud tank and trailer as they were being transported. The line and load were measured several days prior and deemed within safe distance as per regulations. However, a wind storm occurred the night before the tank move and the power pole shifted, causing the line to sag. When the truck drove underneath, the overhead powerline arced on the roof of the mud tank. The tank and trailer sustained extensive damage, and while the driver remained safe, this had a potential to be a very serious incident.